PHBH™: Environmental-friendly Biodegradable Polymer

PHBH™: Environmental-friendly Biodegradable Polymer

HPBH™ is a novel biopolymer produced with sustainable raw materials. It is 100% bio-based and with excellent biodegradability.

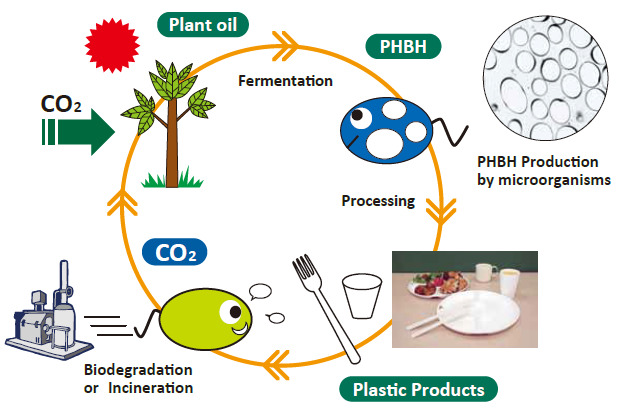

It is produced through Kaneka’s unique microbial fermentation process and could be used in a variety of applications for biodegradable and durable goods. Our resent research shows that PHBH™ also has excellent biodegradable property in marine environment, which contributes to the reduction of marine plastic waste.

Major Features and Advantages

- Excellent biodegradability for composting and bio-gasification

- Biodegradability in sea water which provides a solution to marine microplastics waste

- Usable in a variety of applications as an alternative resin to polyethylene or polypropylene

- 100% bio-based biopolymer, produced by sustainable raw materials, that contributes to an implementable circular economy

Technology Data

Technology data

Possible Applications

PHBH™ is a polyester similar to polyethylene (PE) and polypropylene (PP) and has excellent biodegradable property in various different conditions. For examples, it is compostable at ambient temperature (Home compost), and also biodegradable in soil and sea water. As an alternative resin to PE or PP, PHBH™ can be used in a variety of applications. The most suitable applications are difficult to recollect and sort after use, such as agricultural mulch-film, food packaging, bin liner, fishnet, etc. Moreover, PHBH™ could contribute to solving the issue of plastic waste in developing countries since PHBH™ decomposes into carbon dioxide and water over time when exposed to microorganisms.

Competitive Advantage

PHBH™ is produced by microbial fermentation with plant oils as its carbon sources. PHBH™ can be processed into various plastic products by commonly used equipment. After use, PHBH™ biodegrades in the presence of microorganism into carbon dioxide and water. In other words, PHBH™ creates a carbon neutral system. Moreover, its biodegradability in sea water provides a great solution to the problem of marine microplastic pollution, which has become a major global issue.

Performance

Biodegradability

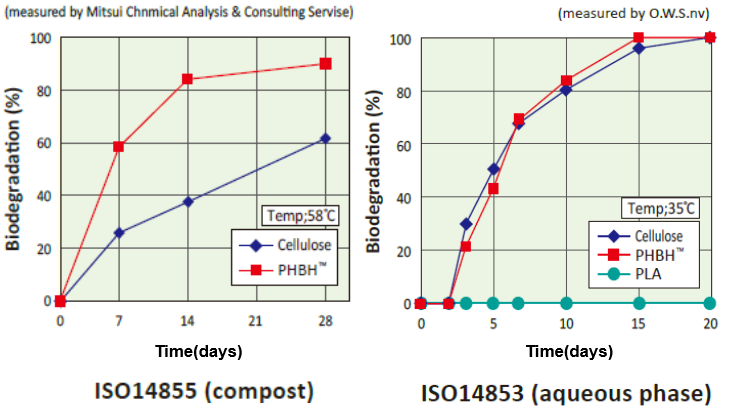

PHBH™ has excellent biodegradability under aerobic, anaerobic, aquatic and composting conditions and is proven to be an environment-friendly plastic.

Composting(aerobic conditions) Bio-gasification(anaerobic conditions)

As illustrated in the above graphs, PHBH™(shown as red) shows the same or higher level of biodegradability than cellulose (blue), which is a standard control according to ISO standards. PHBH™ can transform via biodegradation to reusable resources such as compost and methane gas.

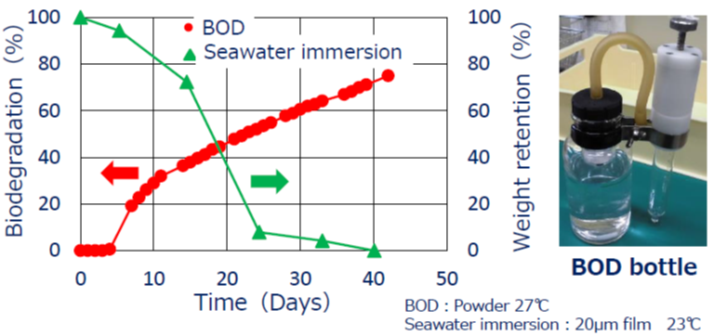

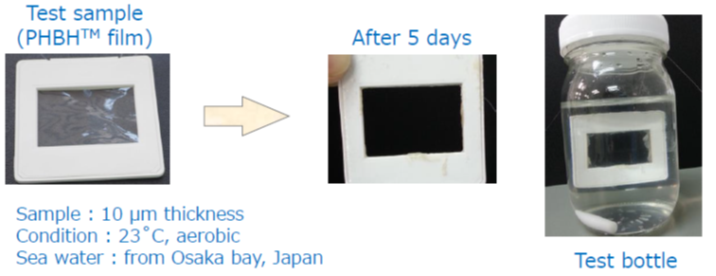

Biodegradability in sea water

1) Biological oxygen demand (BOD) and immersion test

2) Immersion test with thin film

In addition, papers on the biodegradability of PHBH™ in sea water and fresh water were published by T. Morohoshi.

T. Morohoshi et al, Microbes Environ., 33 (2018) 19-25

T. Morohoshi et al, Microbes Environ., 33 (2018) 332-335

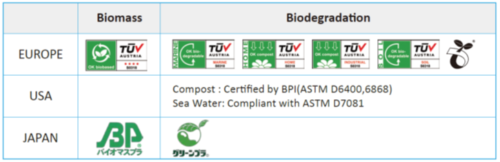

Certification

Among the current available certification on biomass content and biodegradability, PHBH™ is certified by the certification organizations in Europe, USA and Japan listed below.

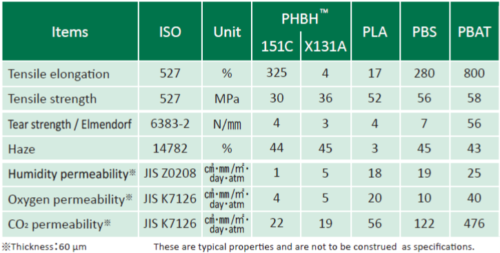

Mechanical Properties

With two grades, 151C as flexible type and X131A as rigid type, PHBH™ can be usable for a variety of applications. PHBH™ has better gas and moisture barrier properties compared to other biodegradable polymers such as PLA, PBS and PBAT.

Technical Maturity / Past Record of Introduction

PHBH™ has been launched to the market since 2008 and is used mainly in France and Germany for fruit & vegetable bags and compostable bags. Yearly sales of of PHBH™ in 2018 has achieved 1150 tons.

In developing countries, we have successfully incorporated PHBH™-based compounds in the production of bin liners in commonly used blown film machine of a Kenyan film manufacturer. In Kenya, we have been supporting the National Environmental Management Authority and the Kenya Bureau of Standard for the introduction of certification and labelling system related to biodegradability. By collaborating with local organizations and conducting technical training to local processing manufacturers, we help to promote understanding and adoption of biodegradable polymer-based bags.

Information of Patent Related to This Technology

Number of Applications: 364 (as of December 31st, 2018)

The representative patents are:

1) Process for the production of 3-hydroxyalkanoic acid copolymers (JP277757, Application Date: Sep.

17th, 1991)

2) Microorganism capable of producing improved polyhydroxy- alkanoate and method of producing

polyhydroxyalkanoate by using the same (JP5670728, Application Date: May 26th, 2009)

3) Microorganism having multiple genes encoding PHA synthase and method for producing (WO2015/146196, Application

Date: Mar. 27th, 2015)

Company Data

Company data

| Name | KANEKA CORPORATION |

| Address |

Tokyo Head Office: Osaka Head Office: |

| Capital | JPY 33,046 million (As of March 31st, 2018) |

| Contact person |

Mr. Mitsutoshi Moro TEL: +81-6-6226-4380 |

| Number of employees |

10,234 (Consolidated, as of March 31st, 2018) |

| Date of company foundation | September 1st, 1949 |

| The type of business | Vinyls and Chlor-Alkali, Performance Polymers, Foam & Residential Techs, E & I Technology, PV & Energy management, Performance Fibers, Medical Devices, Pharma & Supplement Nutrition, Foods & Agris |

International Operation

| Number of employees for international operation(including overseas operation, if any) |

2,499 |

|

| Overseas offices | City , Country | Name of company |

| Brussels, Belgium | Kaneka Europe Holding Company N.V. | |

| Westerlo-Oevel Brussels, Belgium |

Kaneka Belgium N.V. | |

| Brussels, Belgium Eschborn, Germany |

Kaneka Pharma Europe N.V. | |

| Liege, Belgium | Kaneka Eurogentec S.A | |

| Wesseling, Germany | Kaneka Modifiers Deutschland GmbH | |

| Leuven, Belgium | Kaneka’s European Photovoltaics Research Laboratory | |

| Accra City, Ghana | Kaneka Africa Liaison Office | |

| Pasadena, Texas | Kaneka Americas Holding, Inc. | |

| Pasadena, Texas | Kaneka North America LLC | |

| New York, N.Y. | Kaneka Pharma America LLC | |

| São Paulo City, Brazil | Kaneka South America Representative Ltd. | |

| College Station, Texas | Kaneka US Material Research Center | |

| Newark, California | Kaneka US Innovation Center | |

| Newark, California | Kaneka Aerospace LLC | |

| Shanghai, China | Kaneka Asia Co., Ltd. | |

| Shanghai, China | Kaneka Trading (Shanghai) Co., Ltd. | |

| Jiangsu, China | Kaneka Eperan (Suzhou) Co., Ltd. | |

| Shandong, China | HiHua Fiber Co., Ltd. | |

| Guangdong, China | Kaneka (Foshan) High Performance Materials Co., Ltd. | |

| Kuala Lumpur, Malaysia | Kaneka (Malaysia) Sdn. Bhd. | |

| Pahang, Malaysia | Kaneka Eperan Sdn. Bhd. | |

| Pahang, Malaysia | Kaneka Paste Polymers Sdn. Bhd. | |

| Pahang, Malaysia | Kaneka Innovative Fibers Sdn. Bhd. | |

| Pahang, Malaysia | Kaneka Apical Malaysia Sdn. Bhd. | |

| Pahang, Malaysia | Kaneka MS Malaysia Sdn. Bhd. | |

| Jurong Industrial Estate, Singapore | Kaneka Singapore Co. (Pte) Ltd. | |

| Binh Duong, Vietnam | Kaneka Pharma Vietnam Co., Ltd. | |

| New Delhi, India | Kaneka India Pvt. Ltd. | |

| Karawang, Indonesia | PT. Kaneka Foods Indonesia | |

| Bangkok, Thailand | Kaneka (Thailand) Co., Ltd. | |

| Taipei, Taiwan | Kaneka Taiwan Corporation | |

| Seoul, South Korea | Kaneka Korea Corporation | |

| Queensland, Australia | TGA Pastry Company Pty. Ltd. | |

Modality of Business Transaction

Dicrect Investment

We focus on the development of core technologies in Japan, while setting up a production plant in local market based on market demands(investment through equity capital)

Partnership

We work closely with our partners through technical service and product development.

Attachments

Schematic illustration of the technology

KANEKA homepage

English Version: http://www.kaneka.co.jp/en/branch/nb_development/

Japanese Version: http://www.kaneka.co.jp/business/material/nbd_001.html

Kaneka Belgium: http://www.kaneka.be/new-business/kaneka-biodegradable-polymer-phbh

News release

2018.10.15: http://www.kaneka.co.jp/en/service/news/nr20181019/

2018.8.7: http://www.kaneka.co.jp/en/service/news/nr20180824/

2017.11.15: http://www.kaneka.co.jp/en/service/news/nr201711152/

2011.5.12: http://www.kaneka.co.jp/en/service/news/trial-production-system-for-100-plant-based-biopolymer- product-now-operational-new-product-to-be-marketed-as-kaneka-biopolymer-aonilex/

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control / Circular Economy (3R)