Semi-wet Method: Rice Flour![]()

![]()

Producing that Makes the Best

Use of the Original Ingredients of Rice

Starting out to make flour facility for rice flour for Japanese traditional confectioneries and rice crackers, NISHIMURA MACHINE WORKS has specialized in making rice flour as a substitute for wheat flour for about 20 years.

Our rice flour making method is called semi-wet and airflow method. It is unrivaled in its technology for converting rice into rice flour without compromising the quality of the rice. Our rice flour making technology has a 60% share of the Japanese market, and in Southeast Asia, we have an increasing number of customers in Thailand, Vietnam and Myanmar.

Product video

Fig. 1 Principle of rice flour making

Fig. 1 Principle of rice flour making

Major Features and Advantages

Semi-wet and airflow method have characteristics as follows;

- Self-pulverization of rice

- Prevention of starch damage and starch gelatinization of rice

- Moisture control of rice flour

- Sharpening the rice flour size distribution

- Production capacity ranging from small machine of 10 kg/hr to large machines of 600 kg/hr (see Fig. 2)

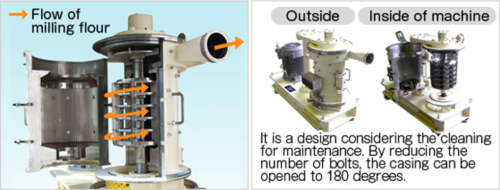

Fig. 2 Images of rice flour making machines (maximum production capacity:

Fig. 2 Images of rice flour making machines (maximum production capacity:

UL 10 kg/hr, UR: 100 kg/hr, LL: 30 kg/hr, LR: 600 kg/hr)

Technology Data

Technology data

Possible applications

Even in a major rice producing country such as Southeast Asia, there has been a recent trend toward westernization of food. For example, the consumption of wheat flour-based breads and western confectioneries is increasing rather than the consumption of traditional sweets. In Southeast Asia, where wheat flour cannot be harvested, the consumption of imported wheat flour is expected to increase in the future. Therefore, we would like to improve the income of local rice producers by effectively using their own rice and promoting the use of rice flour as a substitute for wheat flour, which helps to revitalize local economies.

Moreover, there have been increasing number of children suffering from wheat allergies, the need for gluten-free food is growing in Europe and the United States.

From this perspective, we believe that the demand of our rice flour making technology will be rising.

Competitive advantage

Technology to produce high quality rice flour. We have also realized a manufacturing process with less environmental impact. ‘High quality rice flour’ means rice flour that is highly suitable for food processing; making breads, noodles, western confectioneries and cooking.

Technical features in rice flour production

【Optimization of water usage】

・ Semi-wet method minimizes starch damage compared to dry method.

・ Our equipment consumes as little water as possible (much less than the pasting method).

【Application of airflow】

・ The particle size distribution of rice flour is sharper than the impact method due to the self-crushing method using airflow.

・ Our equipment controls the airflow that enables rice crushing in a short time, developed by hydrodynamics.

・ Discharged airflow can be utilized for drying rice flour.

Performance

・The grinding particle size can be adjusted from 25 to 80μm.

・Starch damage rate can be reduced to 1-5%.

・Moisture content can be adjusted, and equipment capacity of 10 to 600kg/hr can be proposed.

Fig. 3 Comparison of particle size distribution between rice flour making methods

Fig. 3 Comparison of particle size distribution between rice flour making methods

Stamp mill and Pin mill are conventional machines which grind rice with external impact. On the other hand, Super powder mill, our rice flour making machine produces rice flour by self-pulverization, resulting sharp particle size distribution.

Technical maturity / Past record of introduction

The company has been selling its products since 2003, and currently has track record of delivering equipment to about 60 places throughout Japan, such as confectionary manufacturers, Agricultural Cooperative and research institutes.

The company has also exported its products to the following countries.

Thailand: Total3sets for 3 users. Capacity 600kg/hr, 200kg/hr and 30kg/hr.

Vietnam: Total 3sets for 1user. Capacity 600kg/hr×3sets

Myanmar: Total 3sets for 3user. Capacity 30kg/hr×3sets

Taiwan: 1set for 1user. Capacity 30kg/hr×1set

Korea: 2sets for 1user. Capacity 200kg/hr×2sets

Information on patent related to this technology

JP 6317392

JP 5313982

Company Data

Company data

| Name | NISHIMURA MACHINE WORKS CO.,LTD. |

| Address | 2-6-9 Matsuyama-cho, Yao-shi, Osaka, 581-0088 Japan |

| Capital | 40 million JPY (as of 2019) |

| Contact person | Mr. Motoki NISHIMURA E-mail: nmoto@econmw.co.jp Tel: +81-72-991-2461 |

| Number of employees | 58 (as of March 2022) |

| Date of company foundation | August in 1934 |

| Type of business | Manufacturing various types of powder mill |

International operation

| Number of employees for international operation |

7 in Thailand, 1 in China |

|

| Overseas offices | City, Country | Name of Company (if applicable) |

| Nonthaburi, Thailand | Nishimura Powder engineering Co.,Ltd. | |

| Shanghai, China | Our representative office | |

Modality of business transaction

Direct Investment

Main parts are exported from Japan and assembled in Thailand.

Export

Machine can be completed in Japan and Thailand and our supervisor can visit your site to give guidance on test runs.

Attachments

Schematic illustration of the technology

Corporate website (Japanese): https://www.econmw.co.jp/

Column article of our rice flour making method: http://www.rice-flour.jp/

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Agribusiness Technologies : Food value chain