Efficient Treatment of Oil-bearing

Wastewater Utilizing Oil

![]()

Adsorbent, DiaFellow™ DM

DiaFellow™ DM is a high-performance oil adsorbent that enables the treatment of oil-containing wastewater, which was previously difficult to treat with conventional wastewater treatment process. It is applicable for treatment of car wash wastewater at bus and taxi companies, train vehicle bases, hydroelectric power plants, etc.

Fig. 1 The images of DiaFellow™ DM

DiaFellow™ DM consists of lipophilic polyolefin-based polymer compounds and inorganic compounds such as sulfates of alkaline earth metals, etc.

The filtration system by this material enables unmanned, automatic operation and thus operation and maintenance are easy with less workload compared to the conventional wastewater treatment process such as pressurized flotation facility.

Fig. 2 Adsorption column filled with DiaFellow™ DM

We propose the optimal oil-containing wastewater treatment process utilizing this DiaFellow™ DM in combination with necessary pre-and post-treatment processes based on the raw wastewater quality.

Major Features and Advantages

- Oil-containing wastewater can be treated efficiently

- The treated water can be reused as washing water, saving valuable water resources

- Saves energy, chemical and labor compared to the conventional wastewater treatment process

Product guide: Packaged Oily Wastewater Treatment System-DiaFellow DM

Technology Data

Technology Data

Possible Applications

It treats oil-containing wastewater certainly and stably by the advanced oil adsorption technology. In Japan, we have a track record of delivering the technology mainly for treatment of car wash wastewater at bus and taxi companies, train vehicle bases, hydroelectric power plants, etc. Since the treated water can be reused for car washes, etc., it has led to cost reductions for customers.

In addition to buses and taxis, in developing countries where trains are becoming the mainstream in transportation services, it is possible to secure valuable water resources and lead to water circulation by introducing the technology to buses, taxi car washes, vehicle bases, etc.

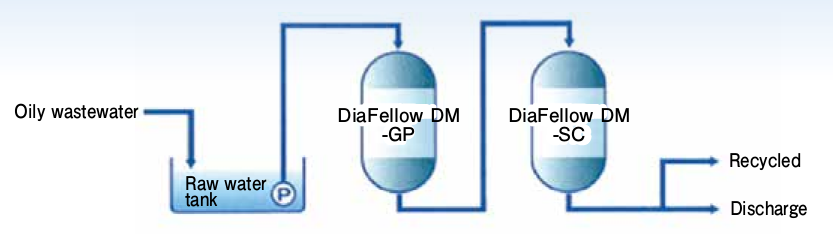

Fig. 3 Basic process flow of the treatment of oil-containing wastewater

Competitive Advantage

Compared to the conventional oil-containing wastewater treatment agents made of polypropylene, DiaFellow™ DM is a granular composite of organic polymer and inorganic compound. The adsorption capacity to oil has significantly improved compared to conventional products. In addition, conventional products could not be backwashed because they float in water, but DiaFellow™ DM can be backwashed because they sink in water.

According to the actual operation data of DiaFellow™ DM, the power consumption was reduced by 35% from 79 kW to 51 kW when compared to the conventional process. Furthermore, the amount of chemicals used has significantly decreased by 98% compared to the conventional one.

Performance

In the current situation where oil-containing wastewater is released into rivers by conventional method or without a proper treatment, environmental pollution is easily imagined. On the other hand, compared to the conventional pressurized flotation process, it has been found that the introduction of this system reduces n-hexane extracts such as mineral oil to about 1/10, directly reducing the environmental burden. With this water quality, it can be reused as washing water or released into rivers, contributing to environmental conservation.

Plant specification

Power supply: 2-5kW(Average power consumption)

Treatment capacity: 3 – 40 m3/h

Replacement cycle of DiaFellow™ DM: 1~3years

Auxiliary: activated carbon adsorption tower, pH adjustment tank (hypochlorous acid or sodium hydroxide is required)

Case of introduction

- Railroad rolling stock base wastewater treatment

Capacity:24m3/d Mineral oil Raw water:45mg/L

Treated water≦2mg/L

Discharge standards:≦5mg/L

- Bus car-wash wastewater recycling

Capacity:5m3/h Mineral oil Raw water:7mg/L

Treated water:≦3mg/L

3.Automobile maintenance factory wastewater recycling

Capacity:4m3/h Mineral oil Raw water:50mg/L

Treated water:≦3mg/L

4.Compressor drainage treatment

Capacity:3m3/h Mineral oil Raw water:100mg/L

Treated water:≦5mg/L

Technical Maturity / Past record of introduction

The wastewater treatment systems utilizing DiaFellow™ DM are installed at over 1,200 sites in Japan as of December 2020.

・Power plants 684 projects

・Industrial 431 projects

・Trains 72 projects

・Buses 61 projects

・Taxis and, etc. 21 projects

The capacity ranges from 0.9m3/h~25m3/h for our past experiences.

Information on patent related to this technology

N/A

Company Data

Company Data

| Name | Mitsubishi Chemical Aqua Solutions Co., Ltd. |

| Address | 2-2, Nihonbashihongoku-cho 1-chome, Chuo-ku, Tokyo |

| Capital | 373.5 million JPY (as of December 31, 2020) |

| Contact person |

Overseas Business Support Dept. |

| Number of employees | 472 (as of April 1, 2021) |

| Date of company foundation | November 1985 |

| The type of business |

|

International Operation

| Number of employees for international operation |

13 | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| Laguna, Philippines | Mitsubishi Chemical Aqua Solutions Co., Ltd. Philippine Branch | |

Modality of business transaction

Partnership

We are looking for a local business partner or a distributor who would actively support promoting and installing our technology and product.

When we find a potential partner(s), we will transfer the technology, necessary for the work above.

Export of product

We can export our products to clients overseas. Even in this case, we will provide necessary assistance through the remote monitoring system.

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Circular Economy (3R)