Food Traceability System for

Safe and Secure Food Value Chain

Safe and Secure Food Value Chain

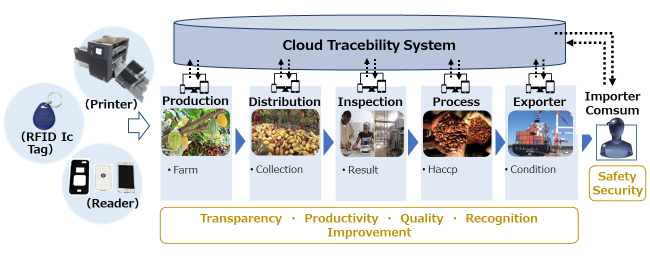

Proprietary direct thermal printer and traceability printing system that utilize tags, QR codes, readers and the cloud web system. From planning to monitoring operations, we propose to establish the comprehensive traceability system to provide solution to achieve safe and secure food value chain.

Fig. 1 Food Traceability System Diagram

Major Features and Advantages

Our strength is that, in addition to the effects of introducing traceability systems to improve the safety and reliability of food and raw materials, improve production quality, and improve operational efficiency, we can propose automation and labor saving of printing, labels, and package work by our Special Printers. Furthermore, our system will contribute to the environmental by reducing costs and wastes incurred from direct printing technology, and provide comprehensive hardware and software necessary for establishing traceability system.

In order to build traceability, it is important to create designs and mechanisms suitable for local issues, needs, applications, etc.. We will take advantage of our strengths, the ability to propose comprehensive solutions to provide systems which meet local requirements and situations. We provide the technology which enables the customers to step ahead of other competitors and increase market share.

Technology Data

Possible applications

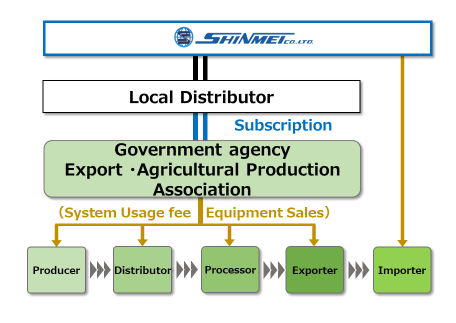

We value safety, security, and trust as key factors for sustainable industrial development in developing countries. Likewise, it is important to ensure comprehensiveness, by involving stakeholders such as the government, organizations, private companies, local communities, and individuals. One way to achieve this in the food industry, which is one of the most important industries in developing countries, is to promote the dissemination of information through food traceability. In light of current situarion where ESG investment attracts worldwide attention, there is a significant trend for private companies to take the SDGs into their management strategies and apply them in business.

|

|

| Fig. 2 Possible Application | |

Competitive advantage

Our strength is that, in addition to the effects of introducing traceability systems to improve the safety and reliability of food and raw materials, improve production quality, and improve operational efficiency, we can propose automation and labor saving of printing, labels, and package work by our Special Printers. Furthermore, our system will contribute to the environmental by reducing costs and wastes incurred from direct printing technology, and provide comprehensive hardware and software necessary for establishing traceability system.

Performance

With traceability printing system, data can be stored permanently in storage. Tracking can be confirmed immediately, so it is possible to respond immediately to inquiries from purchase destinations and consumers by printed QR code or issued RFID IC Tag. (Depending on contract, maintenance, system operation status, etc.)

Technical maturity / Past record of introduction

Printer

It has been 56 years since its founding, with a total of 4000 users. We sell approximately 250 units per a year. Maintenance is carried out in the operation of daily date printing, etc.. The average operating durability is about 13 years. We have been expanding overseas since 2012 and have sold to customers in 27 countries to the present day, and the distributors are located in 18 countries in the world.

Traceability system

Our traceability printing system was developed and commercialized in 2013 after a joint demonstration with the Kyoto Co-op Kyoto Chicken Safety Promotion Council. We are continuing to trade flat-rate models for five poultry farm management organizations (M Farm, F Shoji, S Chicken Garden, N Farm, S Sangyo) that were cooperating with the demonstration. In September 2020, we signed a contract with Y Farm in Yokohama City, Kanagawa Prefecture, to provide a cloud system for egg display truck management. Based on these systems that have already been developed and provided, we have customized and provided them for each customer, and we will flexibly respond to each developing country by checking the setting conditions.

Information on patent related to this technology

N/A

Company Data

| Name | Shinmei Co., Ltd. |

| Address | Fashion Face Building 3F/4F, 2-3-3 Nihonbashi Bakurocho, Chuo-ku, Tokyo, 103-0002 |

| Capital | 42 million JPY (as of October, 2020) |

| Contact person |

Mr. Manabu KAYAMA |

| Number of employees | 67 (as of October, 2020) |

| Date of company foundation | Established: 19 October, 1964 |

| The type of business | Industrial Printer supplier We provide industrial printer and service, maintenance for manufacturing factory. We provide industrial printer about direct printing or labelling on flexible packaging and bag packaging. Shinmei Co., Ltd industrial printer is able to print correctly for information such as expiration date, barcode, QR code coding, identifying marks marking, raw materials and ingredients indicating on flexible packaging, or bag packaging for various products in the industrial manufacturing factory. We look forward to hearing various inquiries from manufacturing factories. |

International operation

| Number of employees for international operation |

5 | |

| Overseas offices |

City, Country | Name of Company (if applicable) |

| Shanghai, China | SHINMEI (SHANGHAI) TRADING CO.LTD (Local Corporation) | |

| Taipei, Taiwan | OLIVE TRADING CO.,LTD | |

| Pusan, Korea | TECHNO MARKING CO.,LTD | |

| Hanoi, Vietnam | TECHNO MARKING VINA CO.,LTD | |

| Wellington, New Zealand | Anken Technology Ltd | |

| Ronville, Canada | Le Fromage au Village Inc. | |

| London, England | The Food Machinery Company Ltd. | |

| Singapore | DJS Resources Pte LtdWin & Celso Pte. Ltd. | |

| Melbourne, Australia | Funktion Australia Pty Ltd | |

| Karachi, Pakistan | Asian machines and Technologies (ptv)Ltd | |

| Bangkok, Thailand | Complete Mark Co., Ltd. | |

| Dubai, UAE | SASCO International Trading LLC | |

| Dhaka, Bangladesh | DB TechnologiesOrck Trade InternationalCORE21 | |

| Kuala LumpurShah Alam, Malaysia | Labelling To Pack Enterprise.PAC | |

| Prague, Czech Republic | ONDRASEK INK-JET SYSTEM SPOL.SR.O | |

| Jakarta, Indonesia | PT.MEGASATRIA HICITER | |

| Yangon, Myanmar | Sai Beacon Trading Co., Ltd. | |

Modality of business transaction

Partnership

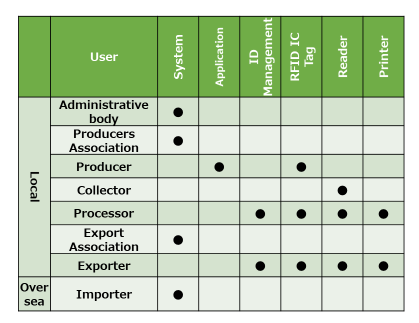

System and application are charged RFID tag, reader buy and sell, special printers, etc. manufacture and sale.

Systems and applications are provided through the cloud web. We export printers and other products from Japan and promote, sell, maintain, and provide after-sales care through local partners or distributors.

Attachments

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Agribusiness Technologies : Food value chain / Production enhancement