Air Conditioning with Zero-energy

by Desiccant Air Conditioning and

Megacool Air Conditioning

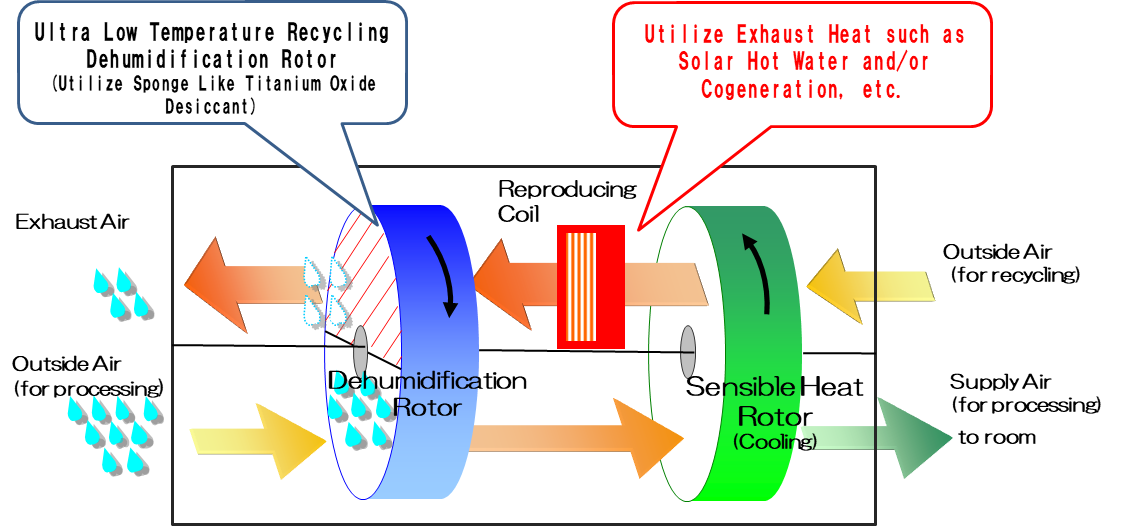

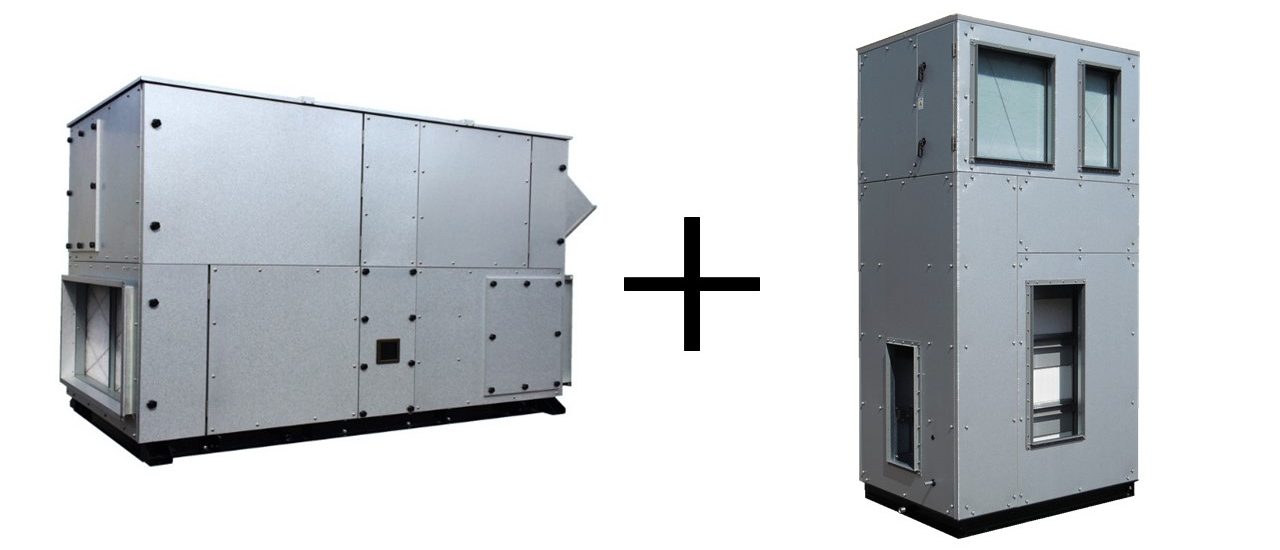

DESICCANT・MEGACOOL® integrates between Desiccant (latent-heat : humidity treatment) and Megacool (sensible-heat : temperature treatment) (the vaporization cooling technology) accumulated by Earthclean Tohoku Co., Ltd.

Fig. 1 Desiccant + Megacool

DESICCANT・MEGACOOL® is a new air conditioning system that introduces outside air with one unit and has basic functions of "cooling", "heating", "dehumidifying", "ventilation", "humidifying", "removing bacteria", "deodorization" and "air purification".

Desiccant Air Conditioner (Nano-wired Titanium Oxide Wheel)

Fig. 2 Desiccant air conditioner

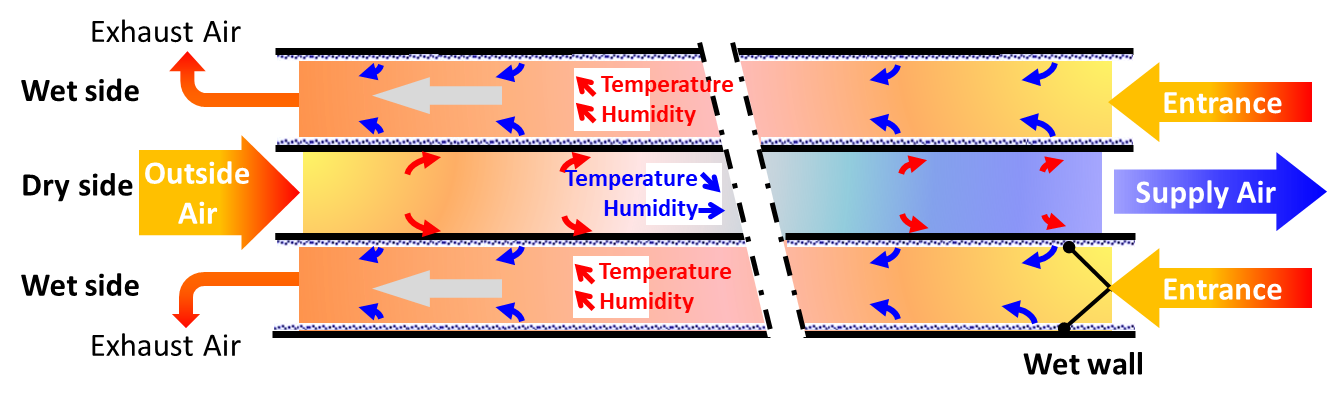

Fig. 3 Mechanism of Desiccant air conditioner

Air conditioner to dehumidify at low temperature. There is a dehumidifying wheel in the air conditioner. It rotates slowly. When the air is passed through the wheel, the moisture in the air is absorbed by the dehumidifying agent of the dehumidifying wheel, and the air is turned into dry air to be supplied air. The air conditioner has two areas, the processing side and the regenerating side. Moisture adsorbed on the processing side is desorbed from the dehumidifying agent by warm air on the regenerating side, and dried so as to able to dehumidify. This operation is repeated and the dehumidification is continuously performed.

Highly efficient and high performance air conditioning unit born from a new desiccant called “Sponge Like Titanium Oxide Desiccant” ※ Joint development with the University of Tokyo. Use renewable energy such as exhaust heat (around 122゚F) and solar water heater by realizing ultra-low temperature recycling through highly efficient desiccants. (contribute to energy saving, promote the use of natural energy, and prevent global warming).

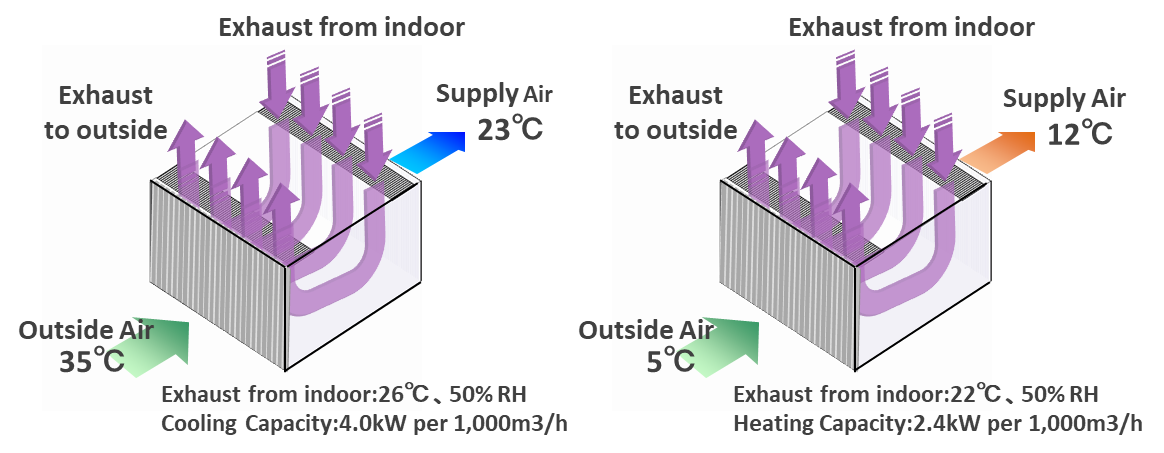

MEGACOOL® (Indirect vaporizating cooler)

Fig. 4 Megacool

Fig. 5 Mechanism of Megacool

Cooling technology using water vaporization phenomenon. The principle is the sprinkling water. MEGACOOL has two parts that Dry side is the suppling air to the indoor, Wet side is cooling the air. Wet side is wet with water. The two airs (Dry and Wet) flow without mixing. Heat exchange is carried out according to the principle of the sprinkling water on the wet wall separating Dry-side and Wet-side. MEGACOOL provides the gentle cool air without overcool. The core structure that enables indirect vaporization cooling (the part where the air is cooled) is a special technology. It uses technology that has high cooling efficiency with a small amount of water and does not transfer humidity.

Major Features and Advantages

<Main features of the system>

- Amenity

- Improvement of the indoor environment (Optimization the temperature and the humidity throughout the year)

- Environment

- Response to global warming (CO2 Emissions reduction: ▲50%~▲80%)

- Utilization of the renewable energy and the exhaust hear energy

- Improvement the efficiency of the energy saving

- Functionality

- Multiple functions in one unit

- Response to a wide range of needs (from the factory to the house)

- Multiple functions (8 effects): “Cooling”, ”Heating”, ”Dehumidify”, ”Ventilation”, ”Humidify”, ”Removing bacteria”, ”Deodorization”, ”Air purification”.

Technology Data

Possible applications

Realization of zero-energy air conditioning by effective use of natural energy, renewable energy and waste heat energy.

In particular, it is an epoch-making air conditioner that can effectively utilize the abundant natural energy (hot water created by sunlight) that is characteristic of tropical regions. As a result, energy saving can be realized and CO2 emissions can be significantly reduced by not using refrigerant gas such as freon.

Competitive advantage

It is an air conditioner that is energy-saving and environmentally friendly. It is possible to use the exhaust heat of various generators, refrigerated showcase, fuel cells, and solar water heaters. Heat consumption can be significantly reduced by using the waste heat of cogeneration generators and showcase refrigerators. In particular, it is an epoch-making air conditioner that can effectively utilize the abundant natural energy (hot water created by sunlight) that is characteristic of tropical regions. As a result, energy saving can be realized and CO2 emissions can be significantly reduced by not using refrigerant gas such as freon gas.

Performance

Excellent energy saving and environmental friendliness.

Comparison with conventional air handling unit (cooling, reheating method)

| Conventional air handling unit | DESICCANT・ MEGACOOL® | |

| Heat energy consumption (When using exhaust heat) |

100% 100% |

63% 0% |

| Power consumption (When using exhaust heat) |

100% 100% |

47% 18% |

| CO2 emissions | 100% | 40% |

| Freon gas | used | unused |

Table 1: Energy Efficiency Comparison

Technical maturity / Past record of introduction

Desiccant unit

Has many achievements in Japan. We have delivered 749 units at food supermarkets, 60 units at production factories, 29 units at food factories, and 12 units at sports facilities and amusement facilities.

Megacool®

Has many achievements in Japan. We have delivered 37 units in commercial facilities, 22 units in production factories, 51 units in food factories, and 12 units in schools, hospitals, and LTCFs.

Information on patent related to this technology

List of patents for desiccant air conditioners (excerpt)

Patent No.3944233: Dehumidifying rotor and desiccant air conditioner equipped with it

Patent No. 5250362: Dehumidifier and its operation control method

Patent No. 4955645: Dehumidifier

Patent No. 5356783: Dehumidifying rotor outer circumference seal structure

Patent No. 6096148: Desiccant air conditioner

Patent No. 4392231: Long fibrous nano titanium oxide

Patent No. 6632174: Air conditioning system and air conditioning method

List of patents for Megacool (excerpt)

Patent No. 4565417: Indirect vaporization cooling system

Patent No. 6078602, 6078609: Indirect evaporative air conditioner and indirect evaporative air conditioning method

Patent No. 6078668: Indirect evaporative air conditioner

Company Data

| Name | Earth Clean Tohoku Co., Ltd. |

| Address | 2-14-17, Izai, Wakabayashi-Ku, Sendai-City, Miyagi, 984-0038, JAPAN |

| Capital | 299 million JPY (as of June 2020) |

| Contact person | Mr. Kenichi KONNO E-mail: hyeasis@earthclean.co.jp TEL: +81-22-288-2888 |

| Number of employees | 30 (as of June 2020) |

| Date of company foundation | Established: July 1989 |

| The type of business |

Designing, manufacturing and sales of desiccant air conditioner, MEGACOOL air conditioner, and related equipment. Air conditioning equipment construction business, maintenance business, wholesale and retail of environmental control equipment. |

International operation

| Number of employees for international operation |

2 | |

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Export of Product

We envision participation in the temperature and humidity control part of the facility construction project.

It is possible to use the exhaust heat of various generators, refrigerated showcase, fuel cells, and solar water heaters. Heat consumption can be significantly reduced by using the waste heat of cogeneration generators and showcase refrigerators. Sales of epoch-making air conditioner that can effectively utilize the abundant natural energy (hot water created by sunlight) that is characteristic of tropical regions.

Differentiate from general air conditioning. Appeal for energy saving.

Sales of epoch-making air conditioners that can significantly reduce CO2 emissions by not using refrigerant gas such as CFCs. Differentiate from general air conditioning. Appeal for energy saving.

Attachments

Schematic illustration of the technology

Catalogues:

Energy-Saving Air Conditioning System – Earthclean Air Conditioning Desiccant

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Energy saving and energy storage

- Agribusiness Technologies : Food value chain