KITA Method for

Sustainable Water Treatment

by Local People

ITKA MACHINERY offers engineering design and installation method of the whole water treatment system for industrial use and drinking use.

Our system is not a packaged product but designed for each site, which makes it possible to optimize piping structure and parameters on site, even in operation. We also have a design, installation and operating know-how of water treatment system as temporary construction.

Therefore, it can be used for wastewater treatment at the contaminated site with heavy metals after removal work of illegal dumped waste. In this way, the initial cost can be cheaper than other conventional plants.

We will offer you the overall process of water treatment, working with you and improving together. We believe local people will be able to continuously install, and operate and manage the water treatment system through our assistance and training.

Fig. 1 Sand filtration device introduced by KITA Machinery (KST)

Major Features and Advantages

・Sand filtration with low flocculant/chemical

KITA Machinery designs wastewater treatment based on sand filtration by gravity flow. It places high importance on minimizing usage of flocculant and other chemicals, in terms of environmental impact.

・Local development

Once local people learn KITA method through the training, they will be able to design, procure, construct and install by themselves. Equipment and parts will be procured locally as much as possible, so it may lead to the local industrial development.

・Movable & Reusable & Cost Efficiency

Possible to design the system mobile type. After treatment is completed at one site, the system can be removed, moved to another waste disposal site (contaminated area) and used again. (Movable & Reusable) The initial cost can be cheaper than other conventional plants.

・Low Carbon Emission of transportation

Parts will be procured locally as much as possible, so there will be no CO2 emissions from transportation from Japan

・Reuse

Local second-hand parts: pipe, tank (steel, stainless) etc. can also be reused.

Technology Data

Possible applications

KITA Machinery believe local people will be able to continuously install, operate and manage the water treatment system to solve the following situation through our technology transfer, and it leads to promotion of health damage prevention.

1) Treatment of contaminated water

・Contaminated water with heavy metals such as arsenic and lead

・Construction wastewater

・Industrial wastewater (such as industrial waste recycling plant, food plant)

・Wastewater containing benzene and other aromatic compound

・Wastewater containing dioxin

As it is possible to propose a purification system for contaminated ground water at a waste pile (waste disposal site), it can improve the living environment of people who must use that water.

Fig. 2 Case of the introduction of wastewater treatment facilities

Fig. 2 Case of the introduction of wastewater treatment facilities

Upper left: Construction site (muddy/turbid water)

Upper right: Industrial plant (water including fly ash)

Lower left: Waste disposal site (wastewater including dioxin, mercury, lead, benzene and arsenic)

2) Producing clean and safe drinking water from

・River, lake and pond water

・Well water

・Rain water

To prevent endemic diseases by providing clean and safe drinking water.

To reduce environmental load by local production for local consumption of drinking water, instead of buying mineral (bottled) water.

We especially have strengths in water treatment using sand filtration, in the treatment mentioned above. This is one of the most sustainable method in the local in terms of cost and ease of maintenance.

Competitive advantage

Our water treatment is carried out in-house in all processes such as understanding the quality of raw water, selection of chemicals, equipment and operation method, engineering design and installation, therefore we have the necessary technology and know-how for water treatment and we can offer the following.

・Flexible suggestion

We can suggest water treatment method according to the request (budget, use or no use of chemicals, etc.) and the condition of raw water on each site. KITA Machinery possesses essential analytical instruments such as GEO-Rex, XRF, GC-IR, etc. to conduct analysis on site.

Fig. 3 KITA MACHINERY’s approach for wastewater treatment

Fig. 3 KITA MACHINERY’s approach for wastewater treatment

・Advanced water treatment technology using sand filtration

We have lots of experience in treating various types of raw water such as producing of drinking water and the treatment of contaminated water with heavy metals such as arsenic and lead by using sand filtration equipped with special backwash system.

・Low initial cost

Equipment and parts will be procured locally as much as possible, so it leads to cheaper initial cost compared to transport all equipment from Japan.

・Know-how at construction site

One of our businesses is the handling of construction equipment in Japan, and we know the conditions of the construction site, therefore we can propose a temporary water treatment. In addition, as we are familiar with the wastewater produced at the construction site (basic aqueous solution including cement or silt), we also have the accumulation of techniques to treat mud water.

Performance

1) Case example at contaminated site with heavy metal in Japan

Treated water volume: 30[m3/hr]

Electricity consumption: approx. 100[kW/hr]

LV: 15[m/hr]

SS(mg/L)】680 (raw water) → < 1 (treated water)

【Dioxins [pg-TEQ/L]】38 (raw water) → 0.071 (treated water)

【Aluminium [mg/L]】0.26 (after application of poly aluminium chloride) → 0.085 (treated water)

【Turbidity [ppm]】310 (raw water)→0.2 (treated water) ※by JIS K0101 (turbidity measurement substance: Kaolinite)

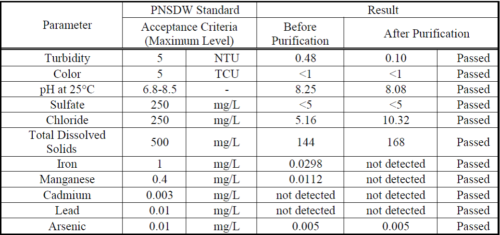

2) Case example in the water supply facility in the Philippines

Treated water volume: 420[L/hr]

Electricity consumption: approx. 600[kW/hr]

LV: 8[m/hr]

Turbidity: 0.48[ppm] (raw water) → 0.10[ppm] (treated water)

Total coliform: more than 8.0 (raw water) → less than 1.1 (treated water)

Technical maturity / Past record of introduction

Certified by Ministry of Land, Infrastructure, Transport and Tourism as New Technology Information System (NETIS) in 2008

【Domestic】Total number of sites – 30

・Case in Aomori, Japan in 2005

Introduction of reclaimed water system in the plant to extract rare metals from fly ash. Installed at a private company, in operation.

・Case in Fukui, Japan in 2009

Treatment of contaminated water during a new road construction at a closed industrial waste stabilization disposal site. Processing was completed and removed from the site.

・Case in Tokushima, Japan in 2014.

Wastewater treatment at the contaminated site with heavy metals after removal work of illegal dumped waste. Processing was completed and removed from the site.

【Overseas】Total number of sites – 1

・Case in the Philippines, in 2015

Pilot Survey Summary Report (Philippines)

Introduction of water treatment system for producing drinking water from waterfall water. (aligned with small hydropower generation plant, see Table 1)

Table 1. Result of water examination

Information on patent related to this technology

N/A

Company Data

| Name | KITA MACHINERY Co.,Ltd |

| Address | Shomachi 3-16, Tokushima-shi, Tokushima, 770-0044 JAPAN |

| Capital | 10 million JPY (as of 31 January, 2019) |

| Contact person |

Environmental Business Div. |

| Number of employees | 241 (as of June 1, 2019) |

| Date of company foundation | April 13, 1961 |

| The type of business |

・Engineering design, procurement, installation of water treatment system and micro hydropower system |

International operation

| Number of employees for international operation |

10 |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Direct investment

If we can find a good technology or partner in the local, we would like to invest them directly and would like the partner to join our business.

Partnership

At first, we would like to export the product and let the local partner maintain it. In the future, we also would like to let the partner assembly the products on sites.

Attachments

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control