Developing a Wastewater

Treatment Infrastructure Quickly and Cost-effectively by FujiClean's System

Treatment Infrastructure Quickly and Cost-effectively by FujiClean's System

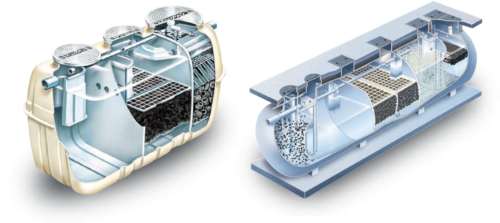

FujiClean system consists of FRP tanks and air blowers. The wastewater treatment technology is based on the biofilm process to remove organics and nitrogen effectively in the wastewater from toilet, kitchen, laundry and shower. The treatment capacity per one unit ranges from 1.0 m3/day to 40 m3/day.

Fig. 1 Basic treatment process

Fig. 1 Basic treatment process

Fig. 2 Images of FujiClean’s system

Major Features and Advantages

- Certified products in Japan, the US, Australia and Germany.

- Easy to maintain compared with centralized wastewater treatment plant.

- Reliable products produced by originally developed semi-automatic molding method.

- Comparable performance to centralized wastewater treatment plant. Organic loading discharging from the FujiClean system to a water body is 1/5 of a conventional septic tank system.

- FujiClean system uses energy-saving diaphragm in air blower to reduce power consumption which contributes to low-carbon emission.

Refer to the Product Catalogue:

Technology Data

Technology data

Possible applications

FujiClean wastewater treatment system enables to develop wastewater infrastructure quickly and cost-effectively in prioritized area by taking advantage of the on-site treatment while developing centralized sewer requires a lot of time in case of unfavourable geographical and geological conditions.

There is a chance to use the effluent from FujiClean system for irrigation since the treated water is as clean as from centralized wastewater treatment plant.

Competitive advantage

- FujiClean’s small footprint system, which has been realized through 60 years of R&D history, enables easy engineering work.

- A public work evaluation report issued by Ministry of Land, Infrastructure, Transport and Tourism indicates that the initial cost of FujiClean system is 50% of conventional centralized wastewater treatment plant in small communities with a flowrate of 300 m3 per day or less.

- FujiClean system can reduce electric cost by 20 – 35% by the high efficiency treatment process and energy saving diaphragm air blowers compared with the other aerobic treatment technologies using diaphragm air blowers.

Performance

【Effluent qualities based on the certifications】

<Japan> BOD:10 – 20 mg/l or less, T-N:10 – 20 mg/l or less, SS:10 – 20 mg/l or less.

<Australia> BOD:10 mg/l or less, SS:10 mg/l or less

<The US> BOD:25 mg/l or less, T-N:19 mg/l or less

(※T-N is approved in a public program)

<Germany> BOD:15 mg/l or less, SS:50 mg/l or less, T-N:25 mg/l or less

【Processable wastewater】

For Domestic wastewater not Industrial wastewater

Influent BOD 500 mg/l or less

Influent T-N 150 mg/l or less

Influent SS 400 mg/l or less

【Lifetime】

The lifetime of the FRP units is indicated as more than 30 years in the manual of prefectural plans of Japanese government (2014).

【Operating conditions】

Power consumption:

Volume of biofilm:

Technical maturity / Past record of introduction

【FujiClean wastewater treatment system with biofilm process】

More than 600,000 units has been installed for 13 years in Japan, Australia, the US, Germany, Vietnam, Philippines, Myanmar, etc.

Overseas users are mainly factory owners, tourist hotel owners and residence owners.

Fig. 3 Construction work for installation

Fig. 3 Construction work for installation

Information on patent related to this technology

Patent number: 6657524 (On treatment method)

Patent number: 6529255 (On flow control)

Patent number: 6494244 (On filter media)

Patent number: 6153380 (On backwashing tube)

Company Data

Company data

| Name | FujiClean Co., Ltd. |

| Address | 4-1-4 Imaike, Chikusa, Nagoya-shi, Aichi 464-0850 Japan |

| Capital | 300,000,000 JPY (as of 14 January 2022) |

| Contact person |

Mr. Masayuki TSUGE |

| Number of employees | 500 (as of 14 January 2022) |

| Date of company foundation | 16 February 1961 |

| Type of business | Manufacturer Design, Production, Sales, Installation, Maintenance for wastewater treatment system |

International operation

| Number of employees for international operation |

30 (Including overseas business department and related departments.) |

|

|

Overseas offices |

City, Country | Name of Company (if applicable) |

|

Australia |

FujiClean Australia Pty Ltd. |

|

|

US |

FujiClean USA,LLC |

|

|

Germany |

AMMERMANN UMWELTTECHNIK GMBH |

|

|

Jordan, UAE, Saudi Arabia, Nigeria, Sri Lanka |

TAICHI HOLDINGS LIMITED(Distributor) |

|

|

Vietnam |

NOMURA TRADING CO., LTD.(Distributor) |

|

|

Philippines |

PHIL-JAPAN WORLDWIDE MANAGEMENT SERVICES, INC.(Distributor) |

|

|

Myanmar |

Trendy Myanmar Co., Ltd. (Distributor) |

|

Modality of business transaction

Partnership

FujiClean exports products from Japan and partners sell the products as distributors.

Attachments

Schematic illustration of the technology

Corporate profile: https://www.youtube.com/watch?v=O9k5HfswkkM

Articles

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control

- Human Health Technologies : Public health