An Efficient Removal Device of

![]()

Particulate Matter and Black Smoke by Semiparmanently Use

C

assette type DPF "MoCobee CT" is the retrofit device for black smoke removal, which is attached on diesel engine and can easily remove 99.9% of black smoke regardless of use condition and engine type. This diesel particulate filter (DPF), developed by COMOTEC Corporation, consists of DPF body and the filter regeneration device with electric heater.

The filter made of ceramic of silicon carbide has simple construction and is free from clogging. Then, "MoCobee CT" is able to be semipermanently recycled by detaching from scrapped vehicles, versatile to use on various conditions (high-sulfur light oil, extreme mount of black smoke exhaust, traffic jam, etc.) and can be installed on various machineries (vehicle, construction machine, forklift, generator, railway vehicle, etc.).

Fig. 1 Diesel particulate filter "MoCobee CT"

Fig. 1 Diesel particulate filter "MoCobee CT"

Fig. 2 Exhaust gas of diesel engine(before and after DPF installation) with the gauze test

Fig. 2 Exhaust gas of diesel engine(before and after DPF installation) with the gauze test

Fig. 3 Condition of DPF before/after installation

Fig. 3 Condition of DPF before/after installation

Major Features and Advantages

MoCobee has characteristic properties and advantages in the following as a diesel particulate filter(DPF)

・Filters made of silicon carbide(SiC) which adds outstanding heat resistance

・Excellent fucntion of PM and black smoke removal

・Semiparmanently usage of filters by appropriate utilization of regeneration device

・Easy installation, replacement and adjustment, corresponding engine specification

Technology Data

Possible Applications

In developing countries, the air pollution due to exhaust gas from diesel engine is a serious problem. The main cause of air pollution is combustion of high sulfur light oil.

This can be because that the price of low-sulfur light oil which exhaust lower particulate matter(PM: fine particle of carbon, hydrocarbon, sulfate, etc.) is more expensive than that of high-sulfur light oil.

In addition, unregulated vehicles which exhaust much black smoke(fine particle of canbon, soot, etc.) have been used due to the high maintenance cost of diesel vehicles to pass the emission regulation. “MoCobee CT” is able to solve these problems.

“MoCobee CT” is able to remove 99.9% of black smoke without clogging in any aged diesel vehicles which use high-sulfur light oil and exhaust black smoke.

Fig. 4 Application of MoCobee (a bus in Mongolia) Fig. 5 Application of MoCobee (a forkift)

Fig. 4 Application of MoCobee (a bus in Mongolia) Fig. 5 Application of MoCobee (a forkift)

Competitie Advantage

“MoCobee CT” is more advantageous than competitive products from the viewpoint of total cost because of the following reasons.

1. Higher initial cost, but cheaper in total

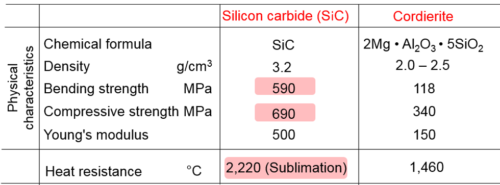

The initial cost of MoCobee is a little bit more expensive than competitive DPF using cordierite or metal filter because “MoCobee CT” is made of silicon carbide(SiC), which has high temperature resistance (see Fig. 1). Filters made of cordierite and metal should be interchanged because these materials gradually wear out to be disposed in the end.

By contrast, the filter of SiC can be used semipermanently. The running cost is cheaper because it is free from the problem caused by clogging which can be happened in device of catalyst type.

Table 1 Comparison of SiC and Cordierite

2. Recyclable

Since the DPF body is able to recycle semipermanently it is economical to utilize detached DPF from scrapped vehicle for new vehicle.

Performance

- Filtering performance

1) PM reduction >90%

PM mainly consists of fine carbon as well as hydrocarbon and sulfate. It has been proved that MoCobee can actually remove more than 90% PM from diesel exhaust gas by an experiment and field tests.

Table 2 The evaluation of PM removal by a chasis dynamo test

※Measured by Japan Automobile Technology Association in 2001. A chasis dynamo meter was used to conduct the experiment in the condition of thierteen modes of diesel automobiles. At the time light oil which had higher sulfur content was used.

2) Removal of nanoparticles

MoCobee has excellent performance to remove even nanoparticles which is smaller than PM 2.5. MoCobee can achieve clean environment by removing nanoparticles completely from closed spaces in construction sites and tunnels.

Fig. 6 Comparison of particle size

Fig. 6 Comparison of particle size

3) Black smoke removal 99.9%

Black smoke normally consist of fine carbon particles. Only quite few black smoke go through the filter.

- Wearability

Advantages of cassette type DPF

(1) When an engines is replaced, it is possible to change the number of filters according to the engine output.

(2) Simple construction of the filters makes it possible to install them freely and easily.

Technical Maturity / Past Record of Introduction

- Year of beginning sales : November, 1999

- Units of sale

(1) DPF for passenger vehicle: >3,500 units

(2) DPF for forklift: > 3,000 units(including OEM)

(3) DPF for construction machine: appox. 50 units

(4) DPF for railway vehicle: approx. 30 units

- Units of export

(1) DPF for bus: 30 units (Mongolia 25, China 5)

(2) DPF for forklift: 30 units (China, Taiwan, Thailand)

Information on Patent Related to This Technology

1. “Device for misuse prevention of emission purification device” : Patent No. P3947681

2. “Carrier for emission purification filter”:Patent No. P3980931

3. “Emission purification device for internal combustion engine”:Patent No. P4874789

4. “Device for rising temperature in exhaust system”:Patent No. P5283201

5. “Device for filter regeneration”:Patent No. P5971645

6. “Filter device for internal combustion engine”:Patent No. P6277489

Company Data

| Name |

COMOTEC Corporation |

| Address |

13-17, Minamisakaecho, Kasukabe-shi, Saitama 344-0057, Japan |

| Capital |

10,000,000 Yen (as of 21th February, 2019) |

| Contact person |

Mr. Soichiro HOSHINO |

| Number of employees | 8 (as of 21th February, 2019) |

| Date of company foundation | December 17, 1996 |

| Type of business | Development and sales of exhaust gas emission reduction device for diesel engine |

International operation

| Number of employees for international operation |

2 |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

We would like to make a distributorship agreement with a local company. We plan to let the persons in developing countries produce parts except main components because it will be possible to make the cost of product down. We will also give them training in Japan how to install and maintain the DPF, not only exporting DPF.

Attachments

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control