"Mishimax": A Volume Reduction

System for Organic Waste

Treatment

M

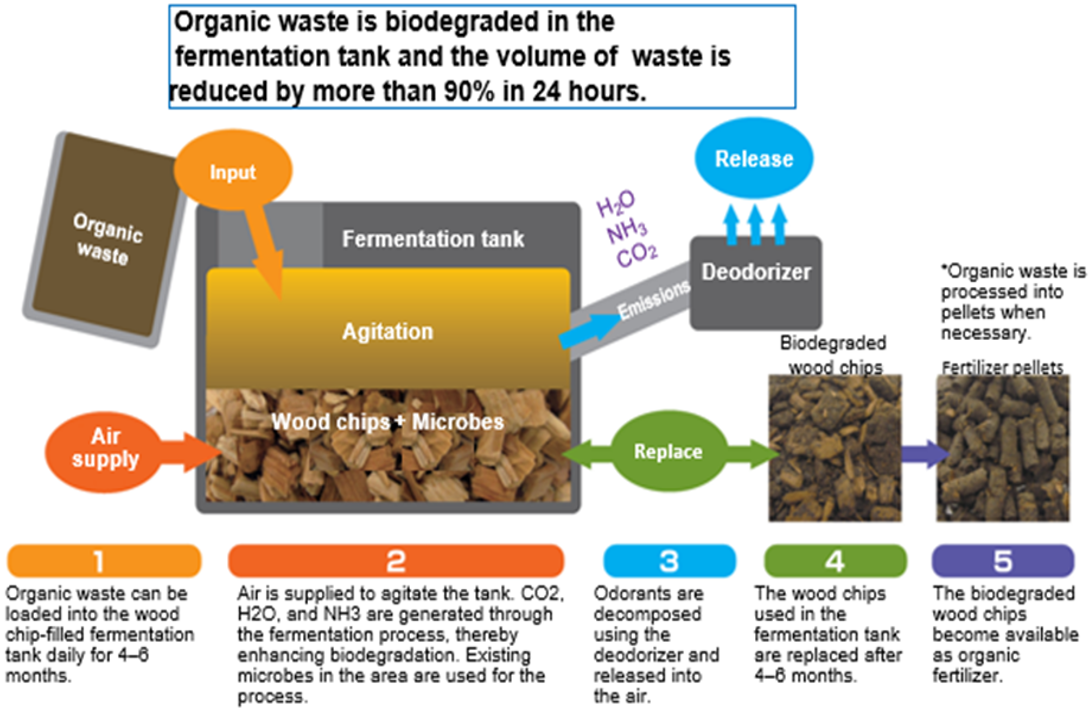

ishimax reduces the volume of wastewater sludge, food waste, and other forms of organic waste by more than 90% in 24 hours, using high-temperature aerobic biodegradation and the heat from evaporation. The organic waste is biodegraded together with the wood chips in the Mishimax fermentation tank. Organic waste can be added to Mishimax every day, but the wood chips are replaced only biannually. After six months, biodegraded organic waste becomes available as organic fertilizer. Moreover, the costs associated with transportation and incineration are not necessary, as Mishimax can biodegrade organic waste on site.

Major Features and Advantages

I. Significant volume reduction of organic waste using microbes in the area

Mishimax’s strength is in significantly reducing the volume of organic waste. The volume can be reduced by more than 90% in 24 hours, which is a very high percentage compared to other similar technologies. In addition, the process can be done using microbes that are native to the area.

II. Reduction of CO2 emissions

By making it possible to treat organic waste on site without incineration, CO2 emissions from transportation and incineration can be reduced by using Mishimax.

III. Efficient and Safe Resource Recycling

With Mishimax, it is possible to add organic waste every day for six months without removing anything. At the end of the six months, the residue can be taken out and used as fertilizer. The residue includes nitrogen and phosphorus, and the other chemicals contained in the residue are confirmed to be safe.

Technology Data

Possible applications

Organic waste is biodegraded using wood chips in the Mishimax fermentation tank. When the biodegradation process is enhanced, the volume of waste is reduced by more than 90% in 24 hours. Organic waste can be added to the Mishimax every day, but the wood chips are replaced only biannually. After six months, the added wood chips are biodegraded together with the organic waste/sludge, and they become available as organic fertilizer. Mishimax has applications at schools, hospitals, hotels, markets, wastewater treatment plants, industrial parks, and other places where food waste or wastewater sludge are produced.

Fig. 1 The Mishimax biodegradation process

Fig. 1 The Mishimax biodegradation process

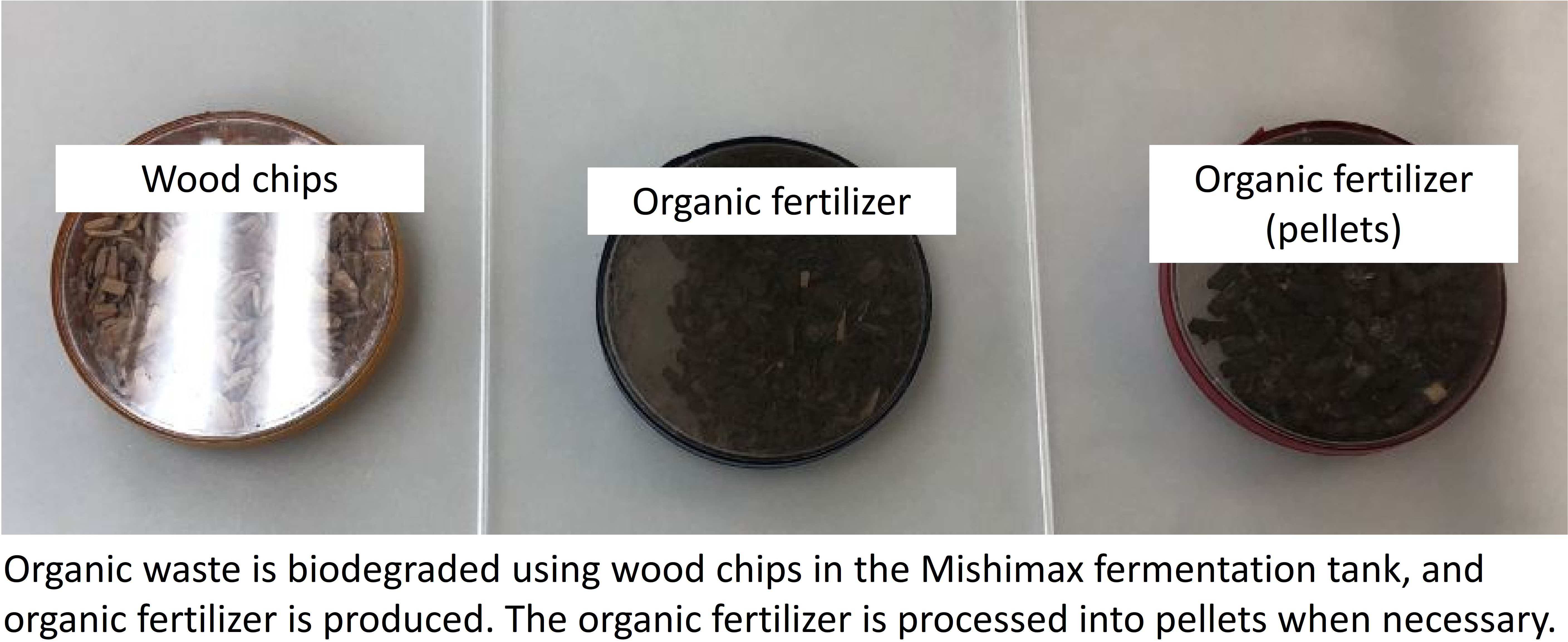

Fig. 2 Wood chips and biodegraded organic waste

The economies of developing countries are growing significantly, and with the population growth, issues such as appropriate treatment of wastes, water security, sewage construction, the reduction of methane and CO2 emissions are increasing. Mishimax could contribute to solve these issues in the following ways.

(1) Appropriate treatment of industrial or household waste: In developing countries, reclamation or incineration (metals are segregated) is commonly used as waste treatment methods. However, several sites have waste problems due to the lack of reclamation lands or an insufficient capacity of incineration facilities. Here, Mishimax can be used as an alternative by reducing the volume of organic waste and providing the organic fertilizer produced from the biodegraded residue. After treatment using Mishimax, biodegraded food waste contains high concentrations of nitrogen and phosphorus, making it useable in farmlands. However, this becomes possible only when garbage segregation rules are set by governments and properly followed by pollution sources. Regarding the legislation, governments’ understanding and cooperation are essential. Therefore, we, Mikuniya Corporation, will discuss with the governments about the garbage segregation rules and make proposals based on global trends, including the SDGs. Also, as a consulting firm, we will provide our clients with environmental consulting services.

(2) Water security: To solve the problem of water shortage, it is necessary to appropriately treat rainwater, lake water, or river water for daily use. During the water treatment process at plants, water is filtered, and large quantities of organic residue is generated. Usually, the costly treatment of this residue is considered a bottleneck. However, Mishimax biodegrades the filtered organic residue, effectively reducing the volume of waste and largely cutting treatment costs. Mishimax can indirectly contribute to the problem of water security in a cost-effectiveness manner.

(3) Sewage construction: When wastewater sludge is generated from industry or households, it often contains harmful substances like heavy metals. In general, activated sludge method is used at sewage treatment plants, which requires huge costs and vast tracts of land. However, when Mishimax is installed at public wastewater treatment plants, private industrial parks, and other pollution sources, it does not require the vast tracts of land, as the sludge can be appropriately managed on site. Mishimax on-site treatment also enables to prevent the leakage of harmful substances by biodegrading sludge in the closed fermentation tank. Moreover, the volume of sludge is effectively reduced, allowing significant savings of treatment costs.

(4) Reduction of methane and CO2 emissions: In some developing countries, there has been a confirmed release of methane from reclaimed lands. Methane is generated through the process of organic waste decomposition due to the inappropriate management of reclaimed lands. However, Mishimax does not emit methane because it teats organic wastes in a closed tank on site. Also, Mishimax on-site treatment reduces CO2 emissions from motor transportation, as there is no need to transport waste for treatment.

Competitive Advantage

- MK-50 (50 kg of waste is biodegraded/day)

Initial cost: Please ask for a quotation.

Reference price: 5 million JPY (Transportation cost is not included.)

Operational cost: Please ask for a quotation.

2) MK-1000 (1000 kg of waste is biodegraded/day)

Initial cost: Please ask for a quotation.

Reference price: 30 million JPY (Transportation cost is not included.)

Operational cost: Please ask for a quotation.

Volume reduction of organic waste: The Mishimax technology specializes in reducing the volume of organic waste through a high-temperature aerobic biodegradation process. The waste volume is reduced by more than 90% in 24 hours by the enhancement of biodegradation and evaporation processes. For treatment, organic waste and wood chips are combined in the fermentation tank (the wood chips are used as carriers). Organic waste and wood chips are agitated with air to activate the existing microbes in the tank. In Japan, wood chips obtained from forest thinnings are used as carriers, as cedar has a porous structure and is suitable for the attachment of microbes. The decomposition environment is prepared by appropriately adjusting oxygen, heat, water and pH levels according to the environments of the installation sites. In the tank of Mishimax, naturally occurring microbes are used, which allows for a safe and secure volume reduction.

Reduction of CO2 emissions: Since Mishimax biodegrades organic waste on site, there is no need to transport the waste for treatment. Therefore, CO2 emissions related to motor transportation are not generated. In comparison with conventional incineration, Mishimax can reduce about 62% of CO2 emissions by biodegrading the organic waste on site (calculated on a LCCO2 basis, 2009 Kanazu). Based on its contribution to the reduction in greenhouse gases, Mishimax was awarded the ‘Low CO2 Kawasaki Brand 17’ by Kawasaki City, Kanagawa Prefecture, Japan.

Resource recycling system: Moreover, it is possible to continue adding organic waste to the Mishimax fermentation tank every day for six months. After six months, the nitrogen and phosphorus concentrations of the organic waste residue in the tank will reach approximately 8%. The residue is analyzed to ensure that it is safe, and then it is registered as fertilizer. After following these processes, the biodegraded organic waste residue becomes useable as organic fertilizer. This is the resource recycling system provided by Mishimax. In Japan, the residue is already being used as organic fertilizer. In developing countries where agriculture is the primary industry, the resource recycling system could be established with the abovementioned processes. The chemical components of the residue are confirmed to be safe.

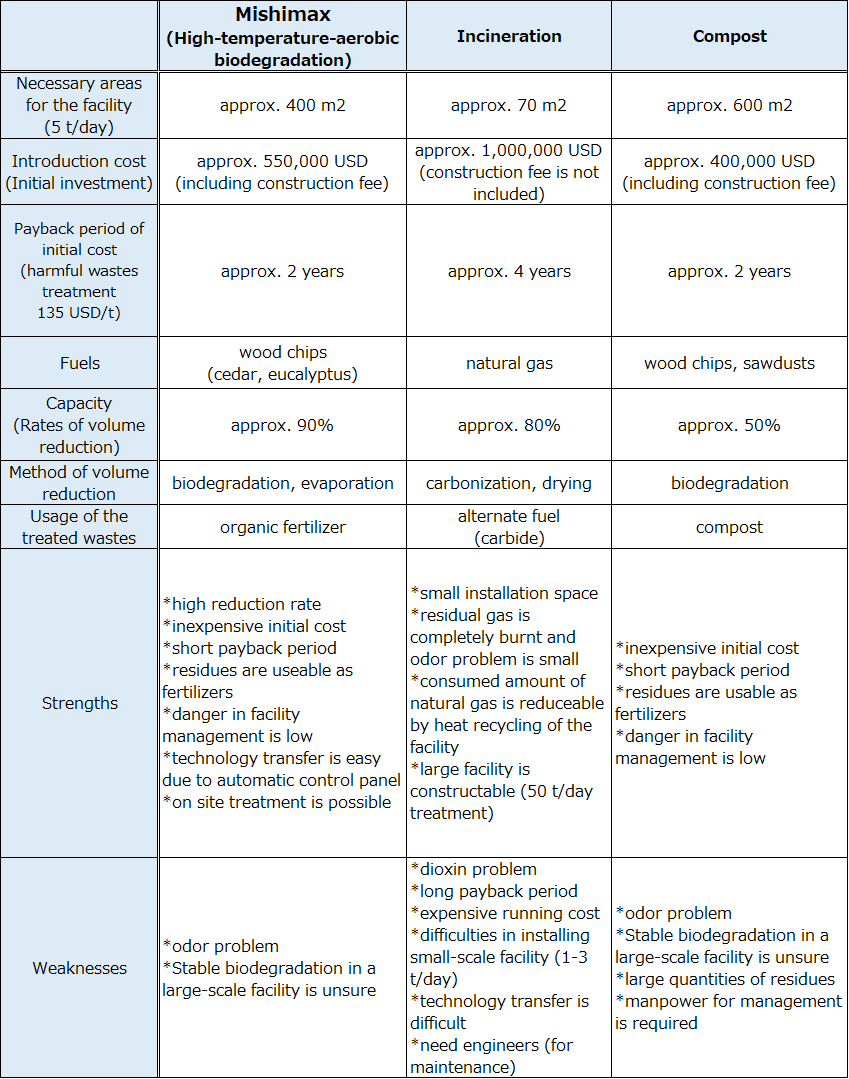

As mentioned above, Mishimax reduces the volume of waste in a cost-effective and environmentally friendly manner, differentiating it from incineration, composting, and other technologies. A comparison table follows.

Table 1. Comparison with other technologies

Performance

Performance for the two types of Mishimax is as follows:

1) MK-50

・50 kg of waste/sludge is biodegraded in 24 hours

・Necessary electric energy: 5.3 kWh

・Necessary quantity of wood chips: 500L/6 months

2) MK-1000

・1000 kg of waste/sludge is biodegraded in 24 hours

・Necessary electric energy: 21 kWh

・Necessary quantity of wood chips: 10,000 L/6 months

(Notes)

・After installing Mishimax, the system requires two months of preparative operation to activate the microbes in the fermentation tank.

・Wood chips are replaced to the fermentation tank every six months. They are biodegraded together with the organic waste/sludge and become available as organic fertilizer.

・Other specifications are also available as custom options. The maximum treatment capacity of Mishimax is 15 t/day.

Technical maturity / Past record of introduction

The technology used in Mishimax is ‘high-temperature aerobic biodegradation’. This technology activates existing microbes in the pores of wood chips and enhances the biodegradation process in the fermentation tank. In the tank, organic waste is biodegraded together with the wood chips, and the volume of the organic waste is reduced by up to 90% in 24 hours. Organic waste can be added to the tank every day, but the wood chips are replaced only biannually. After six months, biodegraded organic waste becomes available as organic fertilizer. By using biodegraded organic waste as fertilizer, nitrogen, phosphorus, and potassium are recycled.

Moreover, associated costs for transportation and incineration are not necessary as Mishimax can biodegrade organic wastes on site. Thus Mishimax contributes to the reduction of CO2 emissions.

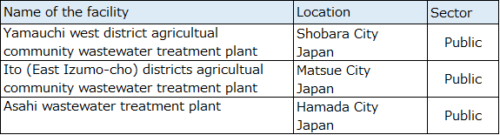

Over forty Mishimax units have been sold, and all orders except MK-50 type were custom-made. So far, our major clients are local governments (food waste treatment facilities, sludge biodegradation facilities, and compost facilities). In Fukushima Prefecture, Mishimax was used for demonstration experiments to reduce the volume of polluted organic wastes.

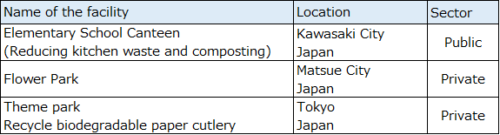

Table 2. Major clients

(Sludge treatment biodegradation facilities)

(Biodegradation facilities for producing organic fertilizers)

Table 3. Demonstration experiments

Information on patent related to this technology

[Patents in Japan]

・Air supply equipment for decomposition tanks: Patent No. 4771734

Company Data

| Name | Mikuniya Corporation |

| Address |

1-403-35-17F, Kosugicho, Nakaharaku, Kawasaki City, Kanagawa, 211-0063 Japan |

| Capital | 10 million JPY |

| Contact person |

Mr. Yuji Tanaka, Ms. Akiko FUJIWARA |

| Number of employees | 197 (as of October 1, 2022) |

| Date of company foundation | 16 October 1985 |

| Type of business | As well as providing environmental and risk consulting services, Mikuniya Corporation is engaged in the development, production, and sales of equipment and products related to our consulting services。 |

International operation

| Number of employees for international operation |

5 | |

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Direct Investment

We plan to establish a company in Vietnam for sales and maintenance of Mishimax. Currently we are intensively approaching local government and Japanese capitalized industrial parks.

Partnership

Regarding the production of Mishimax equipment, we plan to make a partnership agreement with local companies for outsourcing. We are contacting our partner companies and conducting technology transfers.

Attachments

Schematic illustration of the technology

A short movie about Mishimax is published on the webpage of the Ministry of Economy, Trade and Industry, Japan.

http://www.chugoku.meti.go.jp/ip/contents/31/

*The webpage, ‘Mouke no hanamichi’, where Mishimax is introduced, is operated by the Chugoku Bureau of Economy, Trade and Industry, the Ministry of Economy, Trade and Industry, Japan.

(The aims of this webpage are to showcase the highlighted technologies developed by small and medium sized companies, to raise people’s awareness about the intellectual properties, and to promote the use of the technologies.)

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management