![]() PV Ecoline: Low Cost and Efficient

PV Ecoline: Low Cost and Efficient Recycling Technology for Discarded

Recycling Technology for Discarded

Sheet Glass in Photovoltaic Panel

Photovoltaic panels (solar cells) have been widely applied all over the world as renewable energy resources. Since the average lifetime of PV panel is about 20 years, considerable amount of waste PV panels are accumulating every year. Therefore, there are increasing demand for the environmentally friendly process to treat used PV panels. Donico Inter provides ideal solutions for this: to dismantle panels and recycle cover glass and other parts as much as possible, with the simple and efficient process.

Fig. 1 Scheme of the technology

By applying this technology “PV Ecoline”, waste glass in used PV panel can be turned into various forms: glass cullet as a raw material to be processed, or artificial silica sand without edges in corners which alternates natural sand.

Product video (Japanese):

Major Features and Advantages

“PV Ecoline” consists of the three mechanical process on the following. The advantage is easy operation, because artificial silica sand can be produced continuously by directly connecting two or three devices.

- PV aluminum frame dismantling machine “ADFL1”

A device that dismantles the outer aluminum frame for each panel within 1 minute and also removes the JB (junction box) on the back side from the back sheet.

Fig. 2 The image of “ADFL1”

-

PV glass crusher “Crystal Liner”

Panels without frames are crushed by the roll crusher, cover glass (broken into small pices) are separated from other components, and rough glass cullet are collected without contamination. Solar cells are remained on a plate form without a damage.

Fig. 3 The image of “Crystal Liner”

- Artificial silica sand production equipment “Mill Sizer”

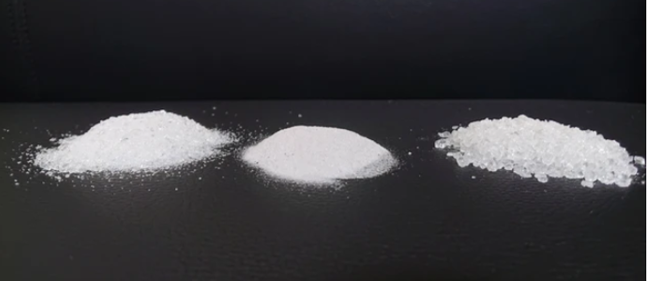

A device that uses a centrifugal crusher to produce safe glass particles (artificial silica sand) without edges in corners from the small pieces of rough glass cullet that are collected by “Crystal Liner”. This finial product, artificial silica sand, can be recycled as raw materials for glass manufacturing. In addition, the finished artificial silica sand can be classified into particle sizes by a vibrating classifier, and the artificial silica sand suitable for the application can be manufactured.

Fig. 4 The image of “Mill Sizer”

Although “ADFL1” is a stand-alone device, it is possible to directly connect all lines by interposing a device for handling the panel after removing the aluminum frame.

Technology Data

Possible applications

PV Ecoline enables to realize the recycling of PV panels to improve profits, reduce waste, and reduce CO2. In addition, this machine is possible to produce artificial silica sand, which can be used as various raw materials for producing sheet glass and bottle glass.

Artificial silica sand can reduce the mining work of natural sand and greatly contributes to resource recycling. As for beach conservation, we are participating to the Ministry of the Environment’s ETV project in Japan.

Regarding the habitat environment of organisms, cooperative research with a national university is currently demonstrating that artificial silica sand can contribute to the creation of shallow sandy beaches that are suitable for the conservation of organisms. By realizing these, it will be possible to create a decarbonized society, create a society in which people and nature coexist, and safe, secure, and comfortable environment, thereby contributing to environmental sustainability.

Fig. 5 The image of artificial silica sand

Competitive advantage

PV Ecoline is classified as a crushing and cutting process. Among them are hot knife, roller grinding, impact crushing, roll compression, and blast crushing, and this method is the roll compression method. The feature is that only the cover glass, which is a brittle material of the PV panel, can be selectively crushed, and the glass can be collected in granules and the cells in sheet form. The aluminum frame has already been peeled off together with JB using an aluminum frame removal device.

Each method has advantages and disadvantages, but this method has the advantages of high operating rate, space saving, and energy saving.

Performance

Since a heat source is not required, it can be processed with a power source of about 50kW. The operating rate is about 1 minute for processing one PV panel.

Technical maturity / Past record of introduction

In March 2022, the first machine was introduced to Company K in Tochigi Prefecture, Japan.

This project was initiated by the company through a public offering for the subsidized project of the Ministry of the Environment Japan (MoEJ) in 2021. Our proposal was adopted by the Ministry, with the recognition that PV Ecoline is the cutting-edge technology and worth promoting to disseminating.

One set of PV Ecoline is ordered and will be commissioned in 2023. Other two sets are expected to be ordered.

Information on patent related to this technology

Obtained Japan patents as Asahi Co., Ltd. for a method of recycling sheet glass as an exclusive right. Donico Inter has concluded an advisory contract with the above company.

- Aluminum frame removal device: Patent No. 6902240

- Sheet glass recycling system: Patent No. 6857889

- Sheet glass crusher: Patent No. 6892095

- Artificial silica sand manufacturing machine: Patent No.7121417

Company Data

Company data

| Name | Donico Inter Co., Ltd. |

| Address | 6F Optex Nionohama Building, 4-7-5, Nionohama, Otsu-shi, Shiga, 520-0801 Japan |

| Capital | 2.1 million JPY (as of January 1, 2023) |

| Contact person |

Mr. Kaneyuki INOKO |

| Number of employees | 2 (as of January 1, 2023) |

| Date of company foundation | 18 April, 2013 |

| The type of business | Consultation of glass recycling technology Design and development of glass recycling machineries |

International operation

| Number of employees for international operation |

1 | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

Intermediate local agents to do business with customers.

Export of product

The device is manufactured in Japan and hopes to export it overseas.

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management