Thermal Insulation Material Using

Biomass: A Better Way to Insulate

J

apan Insulation, founded in 1914, is based in Japan and manufactures and sells heat insulating materials made of Xonotlite-type calcium silicate. To ensure access to affordable, reliable, sustainable and modern energy for all, Japan Insulation has created a technology that uses biomass (rice husks) as a raw material and fuel in order to produce thermal insulation materials.

The thermal insulator can cover the pipes and equipment contained in industrial plants, such as power, refinery and chemical plants. It keeps heat from escaping, improving the energy efficiency of the plant and helping the environment. Not only is the material non-combustible, it is lightweight and environmentally friendly.

Major Features and Advantages

I. High Insulation Performance

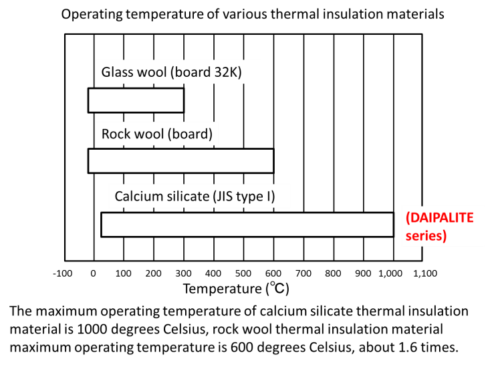

Since this technology uses calcium silicate as the base material, its thermal conductivity can be kept lower under high-temperature (max. 1000C) conditions, compared with other types of insulators that are made of mineral wool. The inorganic calcium silicate thermal insulation materials are supplied to power plants, refinery plants, petrochemical plants, etc. whereby they contribute to these plants, which have high internal temp equipment reaching several hundred degrees. This helps to address heat loss and energy savings due to its high thermal insulation performance.

II. Recycle Rice Husks

Long been known as the industrial waste of agriculture, rice husks are the primary material and fuel used for processing with this technology. This helps to recycle rice husks for a more meaningful contribution rather than simply being thrown away. The technology essentially adds value to the waste, resulting in an indirect positive contribution to the environment.

III. Lower Greenhouse Gas Emissions

By extension, this technology contributes to reduced greenhouse gas emissions by using rice husks as fuel instead of petroleum gas.

IV. Durability

The materials are not easily deformed because calcium silicate thermal insulation materials are molded.

From thermal insulation to energy efficiency, this technology is sought after by many. Japan Insulation Co. has directly invested in a factory in Vietnam and is currently looking for local partners in other countries who will manufacture and/or distribute the product using this technology.

Technology Data

Conceivable applications

【Thermal insulation materials for industry using biomass (rice husks)】(see Attachment 1)

The technology allows production of inorganic calcium silicate thermal insulation materials using biomass (rice husks). The features and benefits are as below:

1) The technology contributes to lowering greenhouse gas emissions by using rice husks as fuel instead of petroleum.

2) The technology reduces waste because it uses rice husks as a raw material.

<Producing process for Thermal Insulation Materials>

3) The inorganic calcium silicate thermal insulation materials are supplied to power plants, refinery plants, petrochemical plants and so on. The materials contribute to these plants, which have high internal temp equipment (around several hundred degrees) as one solution for addressing heat loss and energy saving because of its high thermal insulation performance.

<Thermal Insulation Materials Pipe Cover & Board Products> <Products attached to piping (in Japan)>

4) The materials also contribute to environment because of their long life and high performance and can be reused and recycled.

*Our Japan factory produces the same materials. The difference from the Vietnam factory is that the Japan factory used LNG as fuel and siliceous stone as a raw material instead of rice husk ash.

(website: https://www.jic-bestork.co.jp/modules/smartsection/item.php?itemid=447)

Competitive advantage

Competing technology (materials): Mineral wool thermal insulation materials.

1) Heat resistance

Calcium silicate thermal insulation materials are suitable for high-temperature use (maximum service temperature is 1000℃).

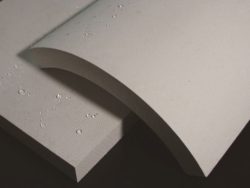

2) Durability (see Attachment 2)

① Is not easily deformed because calcium silicate thermal insulation materials are molded.

② Contributes to protect piping and equipment from CUI issues by using our calcium silicate materials with added water-repellent and corrosion inhibition functions.

<Products with added water-repellent and corrosion inhibition functions>

Performance

Properties of materials produced by the technology

1) Maximum service temperature: 1000℃

2) Thermal conductivity

| at 204°C: | 0.067 W /m・K (JIS-equivalent material) |

| 0.067 W /m・K (ASTM C533 Type 1 material) | |

| *The specification of ASTM C533 Type 1 requires below 0.079 W /m・K. | |

| at 371°C: | 0.090 W /m・K (JIS-equivalent material) |

| 0.088 W /m・K (ASTM C533 Type 1 material) | |

| *The specification of ASTM C533 Type 1 requires below 0.102 W /m・K. | |

In Vietnam, we manufacture the products in the table below.

| JIS type | DAIPALITE-E |

| ASTM type | DAIPALITE-EA |

3) Heating linear shrinkage rate: maximum 2.0%

Technical maturity

- Market share

We have produced calcium silicate thermal insulation materials since 1958. Nowadays, calcium silicate thermal insulation materials account for a majority of the Japanese market for thermal insulation materials for power plants, refinery plants and chemical plants. (Based on internal research).

This is because these plants require high performance and long-lasting materials especially for insulating piping and equipment with high internal temperatures to save energy and contribute to environment.

- Track records of the materials produced by the technology

The Vietnam factory that produces the materials using the technology was completed in May 2016, and has been supplying the materials since October 2016. We have supplied materials in Vietnam, Malaysia, Singapore, Indonesia, Philippines and some other countries since then.

<The Vietnam factory (An Giang Province, The Socialist Republic of Viet Nam)>

Website of Vietnam Factory

https://www.jic-bestork.co.jp/modules/smartsection/item.php?itemid=447

Information on patent related to this technology (if applicable)

In this technology, equipment operation know-how is important.

Company Data

| Name | Japan Insulation Co., Ltd. |

| Address | 1-18-17 Minami Senba, Chuo-ku, Osaka City |

| Capital | 743,760,000 JPY |

| Contact person |

■Technical counterparty ■Counterparty concerning export / distributor |

| Number of employees | 377 (April 2018) |

| Date of company foundation | April 8, 1914 (Established) |

| The type of business | Calcium Silicate Thermal Insulation Materials Manufacturer |

International Operation

|

Number of Employees for International Operation |

About 15 (excluding overseas subsidiaries) | |

|

Overseas Offices* |

City, Country |

Name of Company (if applicable) |

| Vietnam | JIC VIETNAM ONE MEMBER CO., LTD. (An Giang Province) | |

| Malaysia | Representative Office (Kuala Lumpur) | |

| Distributors | Im Korea, Vietnam, Malaysia, Singapore and Indonesia | |

Modality of business transaction

Direct Investment

We have already established a factory in Vietnam.

Partnership

We are manufacturers of calcium silicate insulation materials and are looking for companies that wish to be distributors mainly for Southeast Asian markets.

We want distributors to propose our products as solutions to end users at companies in the fields of power generation, refineries and petrochemicals, and engineering.

We prefer potential distributors that already have experience in thermal insulation business.

Export of product

Thermal insulation materials using biomass in this application are manufactured by JIC VIETNAM ONE MEMBER CO., LTD. (a subsidiary of Japan Insulation Company)

We already have some distributors and they basically sell and export our products to customers.

Licensing of patent

We may offer the know-how for the technology to companies that satisfy the following conditions:

1) The company wishes to manufacture the materials using the technology.

2) We recognize the company as having sufficient technical competence.

3) We recognize that there is no overlap between our target business areas and those of the company.

Attachments

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Energy saving and energy storage

- Environmental Technologies : Circular Economy (3R)