Equipment That Can Improve ![]()

![]()

Water Quality and Water Purification Treatment without Chemicals

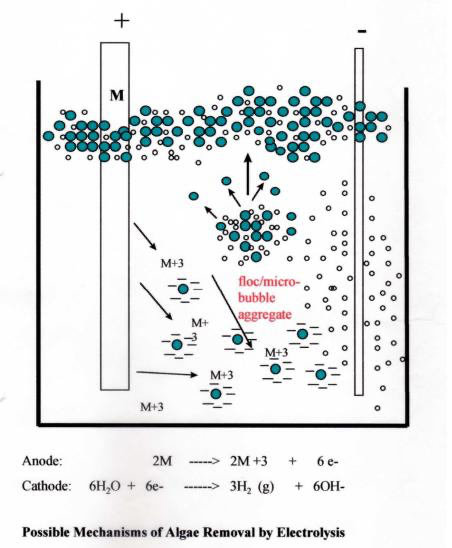

Water quality improvement treatment system that uses electro-physical chemical reactions with no additional agent. Using our self-developed electrode material, a small amount of electrolytes with salt/ industrial salt/ seawater are used to flocculate pollutants by means of electric charges, and solid-liquid separation is performed. Another usage is to decompose and decolorize water that contains organic and nitrogenous compounds through the electrochemical oxidative decomposition process.

・No need for the chemical injection treatment conventionally used in the wastewater treatment process.

・Capable to process both organic and inorganic materials.

・Also effective against persistent substances and enables advanced treatment of a wide variety of wastewater.

・It can remove deposited silica from water, peel off and remove scale blocking pipes in circulating water lines such as in cooling tower systems. The whole process is performed without any chemicals, so no secondary environmental pollution will be caused.

Major Features and Advantages

・Polluted wastewater treatment

It can be used to mitigate pollution in lakes, rivers, and drain water discharged from factories. Wastewater treatment tests are conducted to meet the regulation of discharge standards for rivers, oceans, lakes, marshes, and other specified discharge destinations. The product also provides custom designs to meet the needs of each customer.

・Improvement of circulating water quality such as cooling tower system

As for the water quality improvement system, its primal target is cooling tower systems where water is circulated. Namely, the system can be used for air conditioning, mold cooling, and other kinds of cooling towers owned by factories.

Fig. 1 Images of MICRO WATER SYSTEM

Fig. 2 Scheme of MICRO WATER SYSTEM

Technology Data

Technology data

Possible applications

・Contaminated wastewater treatment

This is a water quality improvement treatment system that uses electro-physical chemical reactions with no additional chemicals. Electrolytes from small amounts of salt, industrial salt, and seawater are used to flocculate pollutants by means of an electrical charge and perform the solid-liquid separation. Another usage is to decompose and decolorize water that contains organic and nitrogenous compounds through the electrochemical oxidative decomposition process. It contributes to the clean-up of polluted water from lakes, rivers, and factory drainage in developing countries and protect limited water resources.

・Improvement of circulating water quality such as cooling tower system

This is a water quality improvement treatment system that uses electro-physical chemical reactions with no additional agent. It can remove deposited silica from water, peel off and remove scale blocking pipes in circulating water lines such as in cooling tower systems. The whole process is performed without using any chemicals, preventing environmental pollution. It can be used to improve the quality of circulating water in cooling tower systems in developing countries.

Note: Both types of treated water described above can be reused as gray water rather than purified sewage water.

Competitive advantage

Since the electrolysis system is chemical-free, it does not induce environmental pollution and is environmentally friendly. Compared to conventional chemical injection and biological treatment, the amount of sludge generated from the purifying process can be significantly reduced. For the solid-liquid separation treatment of substances that are difficult to treat with flocculants, including emulsified oil, nitric acid decomposition, cyanide decomposition, heavy metal recovery, phosphorus recovery, it has a great advantage over conventional technologies in power saving.

It will also contribute to carbon neutrality and CO2 reduction.

Performance

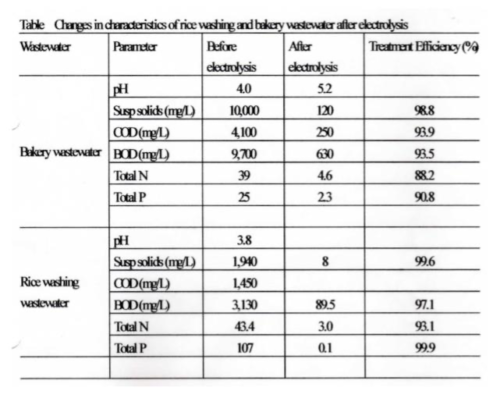

・Treatment of polluted wastewater such as factory wastewater, etc.

For water treatment of 10 m3/day: The estimated amount of consumption of power is 1.5 kW/h and electrolyte (salt) are 2 kg/day (depending on wastewater quality). Filter paper and consumable electrodes are also required.

・Improvement of circulating water quality in cooling tower systems, etc.

For a water storage volume of 20 m3: the estimated amount of power consumption is 1 kW/h. The process also uses consumable electrodes.

・Power supply

The required amount of power supply is AC 220 V 10%.

・Instrument

Monitor ammeter

【Processable pollutants/effluent】

・Separation and removal of emulsified n-hexane extractables

・Separation and removal of heavy metals (lead/copper/nickel/mercury)

・Separation and removal of SS, BOD, fluorine, phosphorus, cesium, arsenic, and other suspended solids

・Decomposition of COD, cyanide, nitrate/ammonia nitrogen

・Decomposition of chlorinated compounds (dioxins)/environmental hormones

・Rust-preventive effect on piping against red rust

・Sterilization/deodorization/decolorization

・Advanced water treatment

・Reduction of generated sludge

Technical maturity / Past record of introduction

We have delivered many products in Japan and overseas, including to national research institutes, universities, and corporations. For details, please visit our website.

MICRO WATER SYSTEM has been applied to the wastewater treatment facility of both in Japan and overseas, a railway company, farm, national research institute, etc.

Information on patent related to this technology

Patent No. JP 3635349

Patent No. JP 6343760

Patent No. US 6706168 B2

Company Data

Company data

| Name | IGADEN Co., Ltd. |

| Address | 78-4 Shinoyama, Joso-shi, Ibaraki, Japan |

| Capital | 10 million JPY (April 1, 2022) |

| Contact person |

Mr. Satoru IGARASHI |

| Number of employees | 5 people (April 1, 2022) |

| Date of company foundation | July 1, 1989 |

| Type of business | Manufacture of machinery and equipment Design, manufacture and sale of water treatment and water |

International operation

| Number of employees for international operation |

2 | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| N//A | N/A | |

Modality of business transaction

Direct Investment

Withdrew IGADEN Singapore Pte Ltd, a designer and manufacturer of electronic measuring instruments. Later the company changed the business to water treatment equipment sales. All overseas sales activities have been outsourced to trading companies that are specialized in related products. Currently, the company is focusing on technology development in Japan and only travels overseas for the purpose of technical research.

Partnership

With the cooperation from trading companies with whom we have concluded confidentiality and sales agency agreements in Japan, we have conducted overseas exhibitions in Vietnam, Thailand, the Philippines, Malaysia, and other countries. In addition to PR activities, the company uses its own website, YouTube, CEO Net Conference, etc., to reach out overseas. To respond to inquiries, local agents visit customers in a timely manner, conduct demonstration tests, and carry out on-site meetings. As for technical support, support is provided by using SNS and other ICT applications such as LINE and Zoom. Since maintenance of the product is easy, it is outsourced to a local firm.

Attachments

Schematic illustration of the technology

Demonstration video of wastewater treatment by electrolysis:

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control