Outline

Conceivable Applications

BGCT JAPAN K. K. and Creative Co., Ltd believes that their product called "RPPWF™" should be a promising alternative fuel resource to coal and oil, prepared from non-hazardous, non-recyclable papers, plastics/plants and woods waste, and other households and industrial wastes.

"Prepared" above means processed, homogenized, and upgraded to a quality for commercial use. Production site for RPPWF™ can be set up locally for regional distribution (i.e. to local power plants).

Alternative resources, which are more sustainable, to coal and oil are highly preferred for electricity generation today to contribute to environmental sustainability.

Competitive Advantage

RPPWF™ is a class 4 solid recovered fuel, registered in the international fuel list CEN 343, and is expected to be the promising alternative resource to coal and oil. For example, RPPWF™ has a higher calorific value (over 25MJ/Kg) than coal (generally between 19-22 MJ/Kg).

Compared to coal, RPPWF™ has about 20% less moisture and approximately 50% less ash. The content of Sulphur in RPPWF™ is almost negligible while coal generally contains up to about 10%.

Technical comparison of properties between coal and RPPWF™

Calorific value of pastics and resins

Furthermore, the CO2 emission from burning RPPWF™ is almost one third, compared to that from burning coal. Because of this ‘green’ characteristics, RPPWF™ is alternatively called Green Coal™ (this name is also a registered trademark).

Long-Term Comparison of CO2 Emissions between Coal and RPPWF™

Long-Term Comparison of CO2 Emissions between Coal and RPPWF™

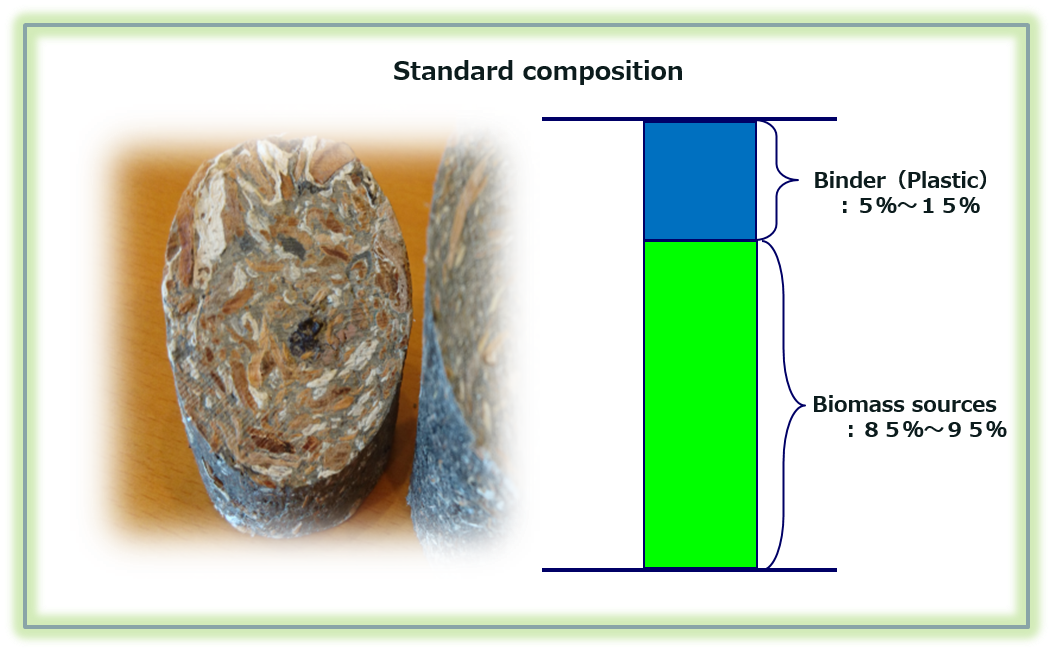

RPPWF™ also has higher biomass contents than conventional biomass resources. In the case of RPPWF™, more than 85% is biomass content (rests are plants or plastics).

RPPWF™ satisfies the European standard for solid recovered fuel, CEN 343, and also has certifications of ISO 14001 and ISO 9001.

Technical comparison of properties among RPPWF™ and other fuels

Technology Data

Technology data

Performance

Because the raw materials for RPPWF™ are 100% biomass (i.e. paper, plant and wood wastes), CO2 emission of the procurement of raw materials can be mostly reduced to zero. Moreover, biomass as raw materials means less cost to procure than any other fuel resources such as coal and oil. Heat recovery rate of RPPWF™ is over 70% and the combustion efficiency is about 98% which are much higher than those of coal and oil.

The CO2 emission reduced from producing RPPWF™ can be used for CO2 credit for domestic and/or international emissions trading.

RPPWF can be composed by wide variety of material combinations. RPPWF can be also manufactured by shredders and molding machines which are sold for commercial use.

※Materials for RPPWF(shredded): Wooden construction waste(left), bamboo (center), plastic(right)

This demonstration shown in the video above was conducted at the factories of the collaborative companies. Nevertheless, the patent of RPPWF is owned by Creative Co. Ltd., and the operational conditions should be advised through technical instruction by BGCT JAPAN Co., Ltd. or Creative Co., Ltd.

Technical Maturity / Past Record of Introduction

We cultivate Amaranthus(※) for the purpose of using effectively fallow rice fields, and aim to produce RPPWF by utilizing it as a part of raw materials. This plan has been discussed minutely among not only the members of BGCT JAPAN Co., Ltd. but also people from nonprofit organizations (NPOs) and universities. We also consider developing this plan through importing biomass material from Southeast Asian countries.

※Amaranthus, collectively known as amaranth, is a cosmopolitan genus of annual or short-lived perennial plants. Some amaranth species are cultivated as leaf vegetables, pseudocereals, and ornamental plants. Most of the Amaranthus species are summer annual weeds and are commonly referred to as pigweed.

Conceivable Risk

Language barrier, law and regulations of candidate countries might become challenges when installing RPPWF™ production line and establishing supply chain network. Climate conditions could affect the long-term reliability of the RPPWF™ production. Good education for operators at the production site must be conducted to maintain the efficiency of RPPWF™ production.

Information on Patent Related to This Technology

Creative Co.,Ltd., headquartered in City of Hiroshima, Japan, owns the patent for RPPWF™. We are the exclusive licensee of RPPWF™.

1. Patent of RPPWF™(Resistered date:24 September 2010)

– Patent No. 4593657

2. Patents related RPPWF™

– Patent No. 4813605

– Patent No. 4814381

– Patent No. 5284939

– Patent No. 5285004

– Patent No. 6059022

Company Data

Company Data

| Name | BGCT JAPAN K. K. and Creative Co., Ltd. |

| Address |

3F, Mizuno Building 2, 5-35-6 Shinbashi Minato-ku, 765 Minamiryuou, Misonou, Saijo-cho, Higashihiroshima City, Hiroshima, 739-0024, Japan (Creative) |

| Capital | 1 million yen (BGCT, As of 6th of February 2018) 50 million yen (Creative, As of 6th of February 2018) |

| Contact person |

Mr. Michihiro KIYAMA |

| Number of employees |

2 (BGCT) |

| Date of company foundation | 18th of May 2017 (BGCT) 30th of March 1991 (Creative) |

| The type of business | R&D and manufacturing of solid fuel, and energy consulting service provider |

International Operation

| Number of employees for international operation(including overseas operation, if any) | ||

| Overseas offices | City , Country | Name of company |

| N/A | N/A | |

Modality of Business Transaction

Partnership

We are looking for business partners who can firstly import our product from Japan to sell in local areas. Eventually we would like to install manufacturing facilities to produce locally for local consumption. We will provide our business partners and their employees with a training for manufacturing and maintenance skills and we will also organize visits to our manufacturing site in Japan.

Licensing of patent

We will offer license of our technologies to our business partners.

Attachments

Schematic illustration of the technology

1. Characteristics of RPPWF™

2. CO2 Emission by Fuel Combustion (t-CO2/t)

CO2 emission at the combustion stage for GREEN COAL can be calculated to be “Zero” because of the principle of carbon neutrality, as well as low CO2 emission of RPPWF.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Renewable energy

- Environmental Technologies : Circular Economy (3R)