Eco-Friendly and Profitable Auto

Recycling System

K

AIHO INDUSTRY CO., LTD. offers a solution that addresses waste treatment and management of ELV (end-of-life) vehicles. This Eco-Friendly Auto Recycling system is designed to address resource circulation society and environmental conservation. Essentially, it is a packaged automobile recycling system comprising three components, which are:

- Installation of automobile recycling equipment and production system

- Installation of computerized business management system called KRA

- Provision of training on automobile recycling technologies and management skills

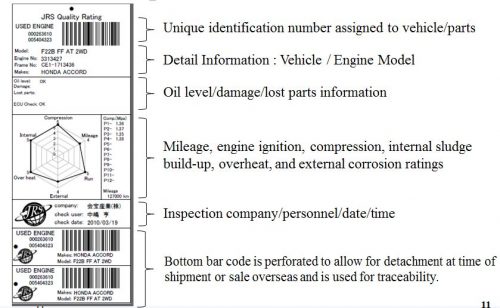

KAIHO INDUSTRY has developed a standard called the Japan Reuse Standard (JRS) for rating the quality of used engines for export.

How end-of-life vehicles (ELV) are handled is a major concern in today’s society, especially when you consider that 1.23 billion cars will become waste all over the world. Thus, there needs to be some kind of appropriate processing and recycling for cars of all kinds.

Major Features and Advantages

I. Ability to Forecast

Utilizing the active cost accounting method within the KRA System, it is possible to forecast the profitability and productivity of operations, as well as evaluate achievement forecasts using the PDCA cycle.

II. Potential for High Sales Volume and Profit

The market demand data acquired through experience with dealing with customers in 85 countries is used for the procurement and production of ELVs and used engines. This makes it possible to boost sales volume and the profitability of each ELV.

III. Eco-Friendly

The fact is, in most developing countries, end-of-life vehicles (ELVs) are often dumped. This has a devastating effect on the environment. By developing a solution to this illegal practice, the environmental will benefit significantly.

IV. Localized / Customized Training Course

KAIHO INDUSTRY CO., LTD. developed custom technical manuals to match the local situation and specific needs of each developing country so that everyone can read and understand the process. A training facility called the International Recycling Education Center (IREC) was created to improve the skills of automobile recycling workers for alliance partners throughout Japan and beyond.

The company’s current operation capacity is approximately 1,200 vehicles per month utilizing the KRA System, exporting 12,000 engines to 85 countries each year. Revenue has grown from 715 million yen in 2003 to 3 billion yen as of 2014.

Technology Data

Possible Applications

|

Today’s big issue is how we handle end-of-life vehicles (ELV) when 1.23 billion cars will become waste worldwide. Appropriate processing and recycling are important problems when recycling cars. Our Eco-Friendly Auto Recycling system contributes to the resource circulation society and environmental conservation. We at KAIHO INDUSTRY formulated a packaged automobile recycling system consisting of these technical components: i. Installing the automobile recycling equipment and production system; ii. Installing the computerized business management system; and iii. Providing training on automobile recycling technologies and management skills. These components are detailed below: i. Installing the automobile recycling equipment Our standardized Japanese recycling technologies will be adapted to the pilot plant. In this production system, ELVs will be collected from the local market and dismantled into mainly scrap metals (such as iron, aluminum and copper) and used recycle parts (such as engines, body parts and suspensions). ii. The KRA system The KRA system is a computerized business management system which allows users to efficiently support the execution of business processes that include automobile appraisals and order / stock / sales management. This system allows the company to manage quality control and inventory control with its extensive use of barcodes attached to individual parts. The barcode system identifies the origin, history, and specs of individual parts and provides vital information to customers. iii. Training on automobile recycling technologies and management skills In 2007, we opened a training center (International Recycling Education Center, IREC) to improve the skills of automobile recycling workers for our alliance partners in Japan and overseas. We convey the technologies and management skills acquired through our 48 years of business experience to trainees through classroom lectures and practical work under the training programs at IREC. |

Competitive Advantage

|

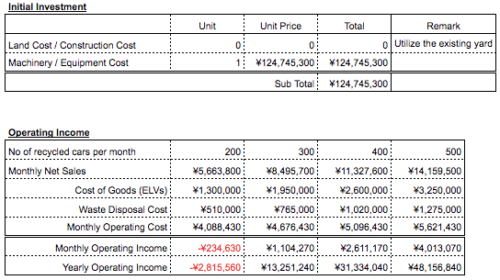

In most developing countries, most end-of-life vehicles (ELVs) are dumped illegally, having a negative impact on the environment. Our Auto Recycling System should be a comprehensive packaged system. We have established the International Recycling Education Center (IREC) to meet the needs of governments and domestic alliance partners. Since 2010, we have received many executive officers and technical experts as trainees from South America, Nigeria, and the Democratic Republic of the Congo, as a part of JICA’s support project. Based on our 48 years of business experience, we have created technical manuals and localized them to the languages of various developing countries. ELVs are collected from local market and dismantled into scrap metal and reusable parts. We have contributed to an increase in the percentage of recycled cars by making items which were considered scrap reusable. (This includes a 2013 Private Sector Proposal Project for a demonstration experiment to establish an eco-friendly automobile recycling system in Brazil, which was supported by JICA.) We assume that 3,600 vehicles will be dismantled per year to estimate business profitability. In case of 6,000 recycled car per year, Operating Income: 48,000,000 yen / Initial Investment: 125,000,000 yen / Payback Period for the Investment: Third Year We have dealt with customers in 85 countries. This market demand is used for the procurement and production of items (ELVs and used engines), which can increase sales volume and the profitability of each ELV. By using the active cost accounting method in our KRA System, we can not only forecast the profitability and productivity of operations but also evaluate achievement forecasts using the PDCA cycle. |

Performance

|

KAIHO INDUSTRY has developed a standard for rating the quality of used engines for export, which we call the Japan Reuse Standard (JRS). It is a quality standard for used products that complements the Japan Industrial Standard (JIS) for new products. The JRS uses a five-level assessment for six items, including engine compression, starting condition, mileage, corrosion, overheating, and sludge. The engine quality is displayed in a reader chart than can be easily understood, regardless of language.

The information provided is considered essential for a sound understanding of the potential life and performance of the engine and related transmission unit. |

Technical maturity / Past record of introduction

Our operation capacity is 1,200 vehicles per month using the KRA System. We export around 12,000 engines to 85 countries annually. Revenue has grown rapidly, from 715 million yen in 2003 to 3 billion yen in 2014.

◆ Sales Result 1: KRA System

We introduced our KRA system to not only our alliance partners in Japan but also our branch offices in Thailand, Kenya and so on.

|

|

No. of Companies and Countries |

|

Domestic |

7 companies |

|

Overseas |

5 countries |

◆ Sales Result 2: Used Engines with JRS

We have produced used engines with JRS for the last 3 years.

|

Period |

Examinations *1 |

Shipments *2 |

|

2012 |

11,728 units |

11,257 units |

|

2013 |

11,497 units |

11,940 units |

|

2014 |

12,235 units |

11,715 units |

*1 No. of Used Engines inspected with the Japan Reuse Standard

*2 No. of shipments of inspected engines

◆ Sales Results 3: IREC

We have trained more than 197 trainees from Japan, Southeast Asia, Africa, and South America.

|

|

Number of trainees |

|

Domestic |

125 trainees |

|

Overseas |

72 trainees |

Conceivable risk

Legal and Intellectual Property Protection

|

Risk |

Measures |

|

Risk that our technology will come into conflict with the law |

We will reduce this risk by partnering with JICA, JETRO, and United Nations Organizations. |

Business

|

Risks |

Measures |

|

Political Instability |

With our partners in the local office of JICA and United Nations Organizations, we will gather related information and tighten security in the areas surrounding our overseas offices |

|

Business Continuity |

To secure business continuity, we will procure ELVs in accordance with local laws and the laws of surrounding countries. This is essential for our business. It is necessary that we hedge against this risk by understanding local laws and customs, as well as our customers’ preferences. |

Society

|

Risks |

Measures |

|

Opposition from the local residents |

When we expand our business to other regions and countries, we will provide explanations of our business to obtain understanding from local stakeholders and our customers. |

|

Opposition from related organizations |

When we expand our business to other regions and countries, we will hire local people who have already been engaged in auto recycling and support their social and vocational independence through technical training. We will examine the expansion of specific business at local government organizations. |

Information of Patent Related to this Technology

Certificate of trademark registration

1. Registration Number ; 5297836 / Trademarked symbol ; JRS

2. Registration Number ; 5321722 / Trademarked symbol ; JRS (Logo Mark)

Company Data

| Name | KAIHO INDUSTRY CO., LTD. |

| Address |

1-25 HIGASHIKAGATSUME-MACHI,KANAZAWA, |

| Capital | 57,000,000 JPY (as of 20 Sep, 2017) |

| Contact person |

Mr. Katsuya BAJI |

| Number of employees | 76 (as of 20 Sep 2017) |

| Date of company foundation | May 1969 |

| The type of business |

Auto Recycling |

International operation

Number of employees for international operation: 20 employees including at our overseas branch offices

Modality of business transaction

Partnership

We provide technical training programs about auto-recycling to local partners who oversee gathering and dismantling end-of-life vehicles.

Our enterprise resources planning (ERP) system can support business process execution, automobile appraisal, and order / stock / sales management.

Our genuine specification test for used engines, called JRS (Japan Reuse Standard), is approved by BSI (British Standard Institution) and it can be provided to local partners who oversee the sales of used engines.

Export of product

In addition to exporting from Japan, we conduct used auto parts auctions. Our procurement network has locations all over Japan. Local partners manage our auction facilities.

Attachments

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management / Circular Economy (3R)