Vanadium Flow Battery System

for Energy Efficiency

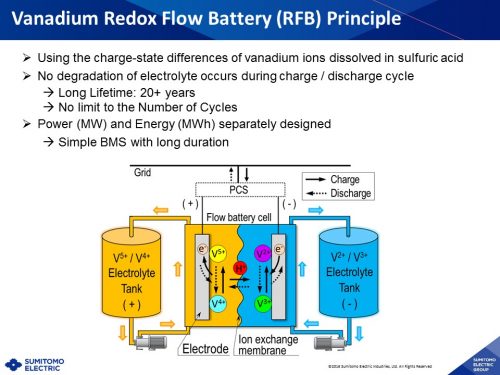

Designed for a 20-year lifecycle, Sumitomo Electric Industries, Ltd.’s Vanadium Flow Battery System brings high energy efficiency to large-scale energy storage systems. The vanadium flow battery (redox flow battery), can absorb and stabilize the fluctuations of outputs predicated by renewable energy sources. Essentially, it’s a large scale energy storage system featuring a vanadium flow battery that charges and discharges depending on oxidation and reduction of vanadium ions in electrolytes.

As such, the lifecycle is long – 20 years – with little to no risk. This is why it can be used on a large scale safely. It also allows for real-time accurate monitoring of the remaining charge, along with ease of operation and virtually no limit to the charge/discharge systems. Perhaps its most notable point is that it is incombustible, which translates to no fire hazard.

Major Features and Advantages

I.Long Life Cycle

I.Long Life Cycle

With vanadium flow battery, the charge/discharge cycle is unlimited (>100,000 cycles). Also the electrolyte is reusable after decommissioning.

II.Safety

The electrolyte used in the battery is non-flammable as it is made of flame retardant materials. Also the battery allows for accurate and reliable SOC (state of charge) management, making it safe to operate.

III.Easy operation

The accurate and real-time SOC acquisition makes it easy to operate. The operational DOD (depth of discharge) is 0 to 100% and operational ambient temperature ranges from -5℃ to 40℃.

IV.Multi-purpose

The battery has high flexibility for different purposes. Both fast response and long duration can be achieved in a single system, and it can be used for hybrid application, for example for flexible capacity batteries.

V.Environment friendly

The electrolyte can be made from recycled vanadium taken from combustion ash. Also as mentioned above, the electrolyte is reusable after decommissioning.

Sumitomo Electric Industries, Ltd. will provide extensive maintenance and operation training to local engineers in order to keep the battery system operating safely. The Vanadium Flow Battery System is cost effective, reliable, and long-lasting compared with traditional battery storage.

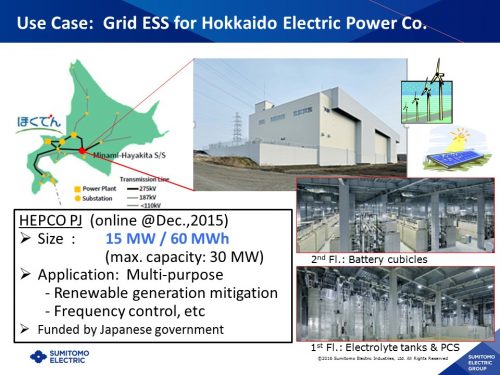

The world’s largest flow battery of 60,000 kWh (15MW*4h), is in operation currently in Hokkaido. In 2017, an 8,000kWh (2MW*4h) flow battery demonstration project will begin in California.

Technology Data

Technology data

Conceivable applications

The vanadium flow battery (redox flow battery) is a large scale energy storage system. It can be used to absorb and stabilize the fluctuations of outputs caused by renewable energy sources. The vanadium flow battery will charge and discharge based on oxidation and reduction of vanadium ions in electrolyte and therefore have a very long life cycle without safety risks. This will enable batteries to be used on a large scale safely.

Competitive advantage

- System designed for a 20-year life cycle

- Real time accurate monitoring of remaining charge, and simple operation

- Incombustible (no fire hazard)

- No limit in charge/discharge cycles

Performance

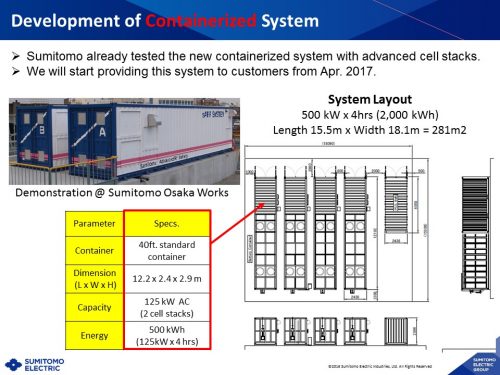

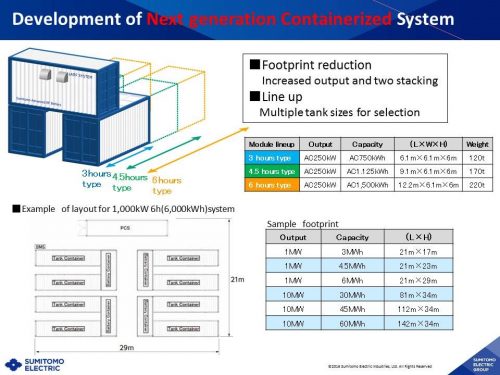

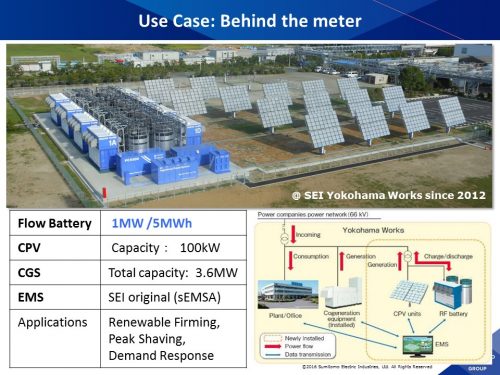

- 1,000kW*5h system performance

- Installation area: 37m*20m (include the maintenance area)

- Capacity: 1,000kW AC

- Energy: 5,000kWh

- AC-AC efficiency: >70%

- Number of Cycles: Unlimited

- Design lifetime: 20 years

- Response time AC(-100% to 100%output): <100msec

Technical maturity / Past record of introduction

- More than 20 years of achievement

- The world’s biggest flow battery of 60,000 kWh (15MW*4h) has been operational in Hokkaido.

- The 8,000kWh (2MW*4h) flow battery demonstration project will start in California in 2017.

Conceivable risk

Constant maintenance is essential for keeping the battery system operate safely. We plan to provide maintenance training to the local engineers, if the recommended maintenance services are not achieved, there will be a risk of significant problems.

Company Data

Company data

| Name | Sumitomo Electric Industries, Ltd. | ||||||

| Address | 4-5-33, Kitahama, Chuo-ku, Osaka, 541-0041 Japan | ||||||

| Capital | JPY 99,737 million | ||||||

| Contact person | Energy System Division E-mail: cpv-contact@info.sei.co.jp URL for inquiry: http://global-sei.com/contact/ |

||||||

| Number of employees | Consolidated: about 241,000 (including 202,000 for international operations, as of April 2016) | ||||||

| Date of company foundation | April 1897 | ||||||

| The type of business | MANUFACTURE OF NON-FERROUS METALS AND PRODUCTS | ||||||

| Overseas offices |

|

Modality of business transaction

Direct Investment

We would like to bring the key product parts from Japan, but the general purpose components shall be obtained and assembled locally.

Partnership

A partnership with an existing company is desirable depending on the countries. For example, we can export the product at first and in the future entrust the maintenance work as well as the product assembly to a local partner.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Energy saving and energy storage