![]()

Breaking Bonds, Reducing Waste: The Power of Active Oxygen in Organic Material Decomposition Technology

Breaking Bonds, Reducing Waste: The Power of Active Oxygen in Organic Material Decomposition Technology

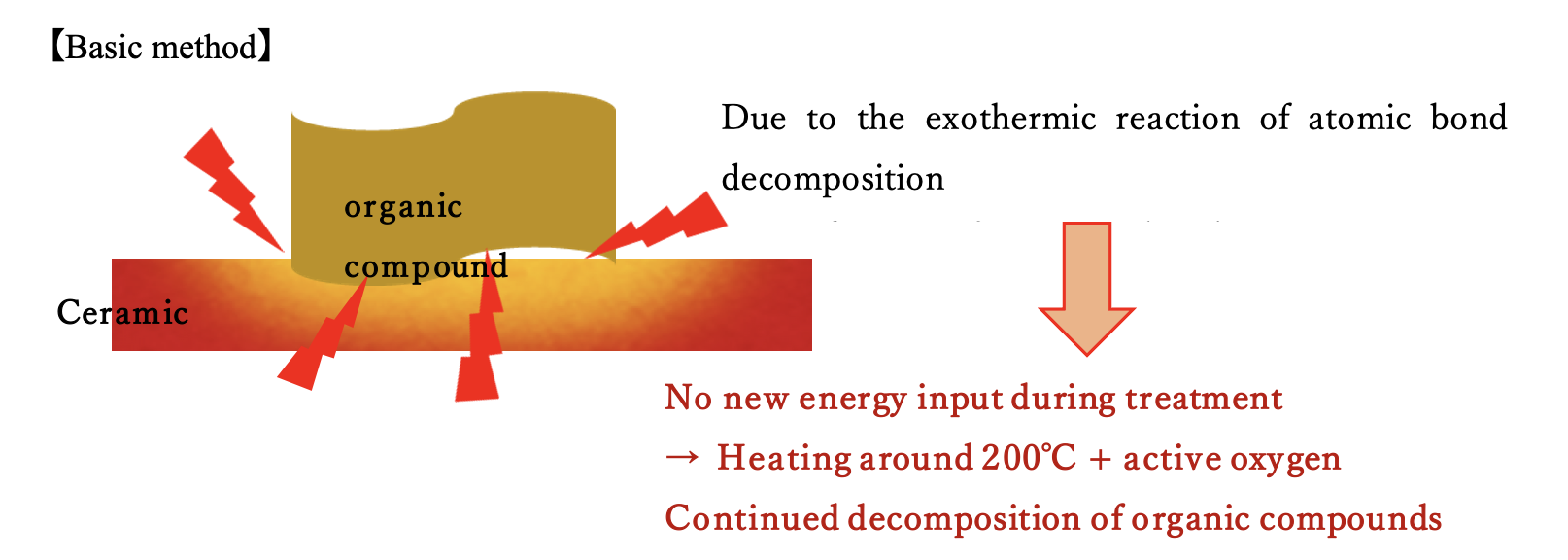

This technology utilizes active oxygen to instantly decompose atomic-level bonds in organic substances, including animal and plant residues and petroleum-derived compounds. The technology boasts several key features, including its ability to decompose and process solid organic matter with active oxygen without the need for burning. By utilizing decomposition heat at around 200°C, it effectively conserves energy. Additionally, it stands out for significantly reducing CO2 emissions compared to conventional incineration methods. The technology adheres to strict emission standards, ensuring that the generation of toxic gases, such as dioxin, remains below acceptable levels. Moreover, the process leaves only a small amount of ceramic residue, making maintenance a breeze.

Major Features and Advantages

The utilization of organic matter decomposition treatment is achieved through thermal decomposition using active oxygen. This innovative process enables the reduction and sterilization of organic residues, such as garbage, and various types of waste, including waste plastic and medical waste, including paper diapers. The technology is so effective that the untreated waste can be reduced to an impressive 1/300 to 1/500 of its original volume. Moreover, sterilization ensures that the treated waste contributes to creating a hygienic environment, making it a vital foundation for promoting a cleaner and healthier way of life.

Figure 1: Decomposition of organic compound

Technology Data

Possible applications

- Sterilization and volume reduction:

It can effectively sterilize and reduce the volume of various types of waste, including household garbage, waste plastics, and medical waste, such as paper diapers, commonly found discarded in different locations. - Hygienic environment:

Sterilizing waste provides a hygienic environment, minimizing the risk of secondary disasters caused by poor hygiene practices. - Human Health Impact Mitigation:

The technology helps minimize adverse effects on human health that may arise from unhygienic waste disposal practices. - Versatile Organic Substances Decomposition:

It can gasify and decompose organic substances from objects combined with inorganic substances, such as small home appliances, solar modules, and waste electric wires, while also facilitating the recovery of valuable metals from such objects.

Figure 2: Examples of decomposed wastes

Figure 2: Examples of decomposed wastes

Competitive advantage

Active oxygen possesses an oxidizing ability approximately 1.3 times that of ozone and exhibits the property of breaking atomic-level bonds. Our technology involves the electrical generation of active oxygen from atmospheric oxygen, which is then brought into contact with the target object for artificial disintegration. This distinctive trait enables the decomposition and treatment of household garbage, non-reusable PET bottles and plastics, medical waste, paper diapers, and more.

- Electricity costs are nearly negligible, as it employs an 80w x 2 active oxygen generator capable of processing 1m3.

- Decomposition occurs within a safe temperature range of 200°C to 300°C, ensuring compliance with Japan’s regulation for dioxin generation.

- Following disassembly, only ceramic ash is emitted, making cleaning the primary maintenance requirement and eliminating other potential issues.

- The technology contributes to reducing CO2 compared to conventional incineration methods, thereby aiding in mitigating global warming.

Performance

- Reduce the processed object to approximately 1/300 of its original volume.

- Decomposition solely relies on electricity consumption, with an 80W x 2 setup of AOS active oxygen generation. (No need for fuel like gas or kerosene during the decomposition process.)

- Processing time varies, taking around 6 hours based on the specific object. (A processing rate of 4m3/day can be achieved by operating a 1m3 capacity machine continuously for 24 hours.)

Figure 3: The mechanism inside the equipment

Figure 3: The mechanism inside the equipment

Technical maturity / Past record of introduction

Domestic

- Utilized by automotive manufacturers for confidential document processing.

- Utilized by food manufacturers to manage residues from processed foods.

Overseas

- Applied for composting sludge in Heilongjiang, China.

- Applied for household waste treatment in Zhejiang, China.

- Utilized for processing food residue in a restaurant arcade in Singapore.

- Utilized for processing food residue in India.

Information on patent related to this technology

- 2019-102989

- 2021-86567

Company Data

Company data

| Name | WEF Institute of Technology Inc. |

| Address | 1-19-15 Do Otsu,Shiga 520-2116, JAPAN |

| Capital | 20.5 million JPY (as of August, 2023) |

| Contact person |

Mr. Akira Aoyama |

| Number of employees | 5 (as of August, 2023) |

| Date of company foundation | July 27th, 2016 |

| The type of business | Consulting and Sales of products related with environmental technology |

International operation

| Number of employees for international operation |

1 | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| Xi’an City, Shaanxi Province, People’s Republic of China | Xi’an Liqi Environmental Protection Technology Co., Ltd. | |

Modality of business transaction

Partnership

Key components are imported from Japan, while generic components can be sourced and produced locally.

Export of product

We intend to export our products from Japan, selling them locally while also offering comprehensive after-sales services.

Attachments

Schematic illustration of the technology

- Detailed explanation of the principle: https://aoyama-wefit.com/en/product/energy.html

- Product overview (video) – Japanese only, old version

- Factory residue treatment (video)

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Waste treatment and management

- Human Health Technologies : Public health