Two Ugandan trainees under the UNIDO ITPO Tokyo’s “STePP Industrial Vocational Training programme in Africa” travelled to Japan in November 2023 and successfully completed a one-month training to learn Japanese automotive recycling technology from a Japanese company, Kaiho Industry Co., Ltd. in Kanazawa City, Ishikawa Prefecture. During their training, they learned automotive recycling and dismantling techniques from Kaiho Industry at their factory and training centre. Since Uganda is facing environmental problems and health issues due to the lack of appropriate recycling technology for end-of-life vehicles, the two trainees will conduct training to disseminate the technology and know-how they acquired in Japan in their home country.

The two trainees are instructors in charge of automobile repair and maintenance at the Nakawa Vocational Training College in Uganda.

Photo Caption: Mr. Aretor Zerubabel (right), Mr. Sebanakitta Wilson Kaaya (left)

“Which parts can be reused?” Learning how to properly dismantle an end-of-life vehicle

“What’s next?” “Which one is pure iron?” In late November, Kaiho Industry’s Japanese staff and the Ugandan trainees were carefully examining an end-of-life taxi at Kaiho Industry’s factory. The two trainees, through initially struggling with the procedures and tools required, carefully sorted the parts into recyclable parts, same material parts, waste, and so on. This scene is from the “self-dismantling” training, where trainees had a hands-on experience in dismantling ELVs based on the knowledge they have learned during the training.

Removing parts from a car based on the right procedure

Removing car parts and sorting recyclable items

In this training programme, Kaiho Industry, which has safe and environmentally friendly end-of-life vehicle recycling technology, conducted the training. The two trainees spent nearly a month at the company’s accommodation and training centre, where they learned how to dismantle end-of-life vehicles and sort automotive parts, as well as Japanese guidelines and regulations regarding safety requirements during dismantling. They also discussed with Kaiho Industry’s staff on how to adapt this technology to Uganda. At the company’s dismantling factory, the trainees received practical training in dismantling a total of five vehicles with different structures.

While engaging in such practical training, the two trainees, with the support of Kaiho Industry, recorded the knowledge and practices gained from their daily training and completed a 177-page manual covering the procedure for dismantling end-of-life vehicles, titled “Recycling of End-of-Life Vehicles – A Guide for Environmental Protection, Safety and Profit”. The guide will be used in phase 2 of this project, which will be implemented in Uganda in 2024.

Spreading Japanese Automobile Recycling Technology in Uganda

What kind of knowledge and technologies did the two trainees gain through their training in Japan? UNIDO ITPO Tokyo interviewed the trainees about their thoughts on the training and their motivation for phase 2 of the programme.

Mr. Aretor stated, “I used to remove car parts without any knowledge so far, but through this training, I was able to learn the proper way to dismantle cars considering the environment and safety. It was a wonderful experience for me to learn about the technology, equipment, and know-how of handling end-of-life vehicles, which I had never experienced before.”

Mr. Sebanakitta also mentioned, “I have learned how to properly use the tools and equipment to handle automotive parts. I will apply this knowledge to teaching students at our vocational training college. If we can spread the technology in Uganda, the level of automotive-related skills in the informal sector will be enhanced, and we can contribute to job creation in the country. This project will also help solve many of Uganda’s environmental problems.”

According to the trainees, there are no proper places to dispose of end-of-life vehicles in Uganda, and automobile oil and Freon gas are not disposed of properly, leading to pollution of water, soil, and air. They participated in the programme with the aspiration of changing the situation in their home country. In 2024, when phase 2 of the project begins, the two trainees will serve as instructors to transfer the automotive recycling techniques they learned in Japan to students at the vocational training school where they work.

For phase 2 of the project, Mr. Aretor emphasized, “Kaiho Industry’s recycling technology is beneficial to the environment and safety, as well as to new businesses that recycle automotive parts. I would like to share this experience and knowledge with my colleagues and students first at our college, and I will serve as a bridge to spread the technology to Africa”.

Conveying Japan’s “clean-up afterwards” spirit through technology transfer

Mr. Sasuke Hashimoto of Kaiho Industry, who was in charge of the training as the instructor, said, “Both trainees were very enthusiastic about the training from the beginning and showed a willingness to learn about the technical aspects for the purpose of environmental protection in their own countries. I am sure that this attitude will lead them to the success of the next phase of the project”. On the other hand, Mr. Hashimoto noted that the condition of end-of-life vehicles differs between Japan and Uganda in terms of minor details such as the degree of rust and bolts. Thus, the two trainees will need to take the lead in the phase 2 to develop the training customized for Uganda.

Mr. Hashimoto also expressed his thoughts on this technology transfer programme, saying, “There is a tremendous flow of used cars from Japan to Africa, but the problem is that they are not properly sorted and disposed of. Japanese companies are required not only to sell their products but also to transfer the technology of sorting and disposing of end-of-life vehicles based on the Japanese spirit of ‘Atoshimatsu’ which means cleaning up afterwards.”

Photo caption: Mr. Sasuke Hashimoto, Mr. Atsushi Yamaguchi of Kaiho Industry, Mr. Aretor and Mr. Sebanakitta (from left to right in photo)

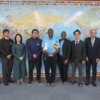

On 1 December, the last day of the training programme, the closing ceremony was held with the participation of Mr. Takayuki Kondo, President of Kaiho Industry, Ms. Fumio Adachi, Head of UNIDO ITPO Tokyo, as well as online participants from the Embassy of Uganda in Japan. The two trainees presented what they had learned in one month and expressed their thoughts and motivations for phase 2 of the programme. Finally, Ms. Adachi awarded the two trainees with certificates of completion, thus concluding their training in Japan.

The project implemented an on-site training in Uganda (Phase II) in May 2024.

Learn more about Phase 2.