![]()

![]() Triple the Protection: Proguard’s Multi-Layered Packaging Film for Extended Freshness

Triple the Protection: Proguard’s Multi-Layered Packaging Film for Extended Freshness

In sufficient access to essential resources, limited infrastructure, and inadequate storage in developing countries can result in significant post-harvest losses which threatens food security. “Proguard” offers a transformative solution to these challenges. "Proguard" is a plastic film for packaging with various functions to enhance the shelf life of food products and drinking . It is effective not only for local food security but also offers a reliable solution for export and transportation, addressing the challenges of preserving food during transit. The properties of "Proguard" can help developing countries opens new business opportunities in agricultural, livestock, and fishery products. The film is composed of three laminated layers that possess different functions, with antimicrobial agents and antioxidants included in the innermost film at a certain ratio, which adds several benefits that cannot be achieved by a single film. Combined with a high-tightness fastener, "Proguard" functions effectively against the contents of the bag while providing a package that can be easily reused.

Figure 1: Three-layer construction and high-tightness fastener

Major Features and Advantages

The main features of "Proguard" are (1) odor resistance, (2) moisture resistance, (3) insect resistance, (4) fungicide resistance, (5) antiseptic properties, (6) gas/water vapor transmission control, and (7) UV light transmission control.

- Odor resistance and gas permeation control:

Inhibits the outflow and inflow of gases and odors, from inside and outside the bag respectively. → Effective for packaging foodstuffs with strong odors or prone to deterioration by oxidation. - Moisture-proof property, suppression of water vapor permeation:

Inhibits the outflow of water vapor present within the bag. Also suppresses the inflow of water vapor from the outside of the bag. → Effective for packaging moisture-sensitive foodstuffs and food products that contain a certain amount of moisture. - Insect repellency:

Serve as a protective shield against insects. → Effective for packaging food products that may be susceptible to food damage, and ensuring the extended storage of perishable goods. - Fungicide resistance:

The innermost layer of the film possesses antimicrobial agents. The synergistic effects of antimicrobial agents and antioxidants is effective in limiting the growth of microorganisms. → Prevents the spoilage of stored items, including products of which freshness is of particular commercial value such as raw fish and meat. - Bactericide resistance:

Antibacterial properties on the film’s contact surface (innermost layer), and airtight space secured through three laminated layers. → Enduring preservation of drinking and living water. Additionally, it prevents discoloration of meat, contributing to the maintenance of food quality over time. - Preservative property:

Extended freshness retention period for contents. → Stable storage of agricultural and livestock products. Note: the effectiveness of preservation is expected to vary depending on the type of contents and the surrounding environment. Tests are required. - UV light transmission control (*UV light transmission control is an optional feature):

Prevents the transmission of ultraviolet rays to the contents of the bag. → Prevents colour burn of vegetables. This feature can also be applied to preserve clothing, ensuring stable storage of garments.

Figure 2: Spoilage odor permeation test and appearance of raw pork after two months of storage at room temperature

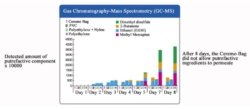

Technology Data

Possible applications

By standardizing packaging that takes advantage of “Proguard” functionality, it may be possible to extend the freshness retention period of foodstuffs, drinking water, and other products. It could contribute to the stable supply of foods, extension of the distance over which they can be imported and exported, and stable storage of drinking water.

“Proguard” standardized packaging can benefit a range of products, including fruits (e.g., berries and vegetables), staple foods (e.g., rice and wheat), meat and poultry, bakery items, dairy products, processed foods, and beverages. Its effectiveness extends to specialty crops like coffee beans and tea leaves. This standardized approach enhances freshness, reduces post-harvest losses, and facilitates the global supply chain for various agricultural and food products.

Competitive advantage

“Proguard” is an internationally patented product. J-Chemical Corporation possesses unique know-how in production, making it difficult for other companies to imitate their product.

No large capital investment is required to introduce the product. In addition, the simple design of the bag with zipper does not require highly specialized operations.

Performance

Test to measure the moisture content of white rice

Test Summary

- Bags tested:

- Storage bags made of “Proguard”

- Nylon polyethylene bag

- Rice used: Koshihikari produced in Nagano Prefecture

- Storage environment: Room temperature

Changes in moisture content of white rice purchased at a mass merchandiser were measured over a period of time when the rice was stored in (1) “Proguard” storage bags and (2) the bags in which the rice was packaged at the time of purchase.

Test Results

Change in moisture content of white rice (%)

| Sample | Test start date | After 1 year | After 2 years | After 3 years |

| “Proguard” storage bag | 14.2 | 14.2 | 14.0 | 14.0 |

| Nylon polyethylene bag | 14.2 | 13.8 | 13.0 | 12.6 |

It was confirmed that storing white rice in “Proguard” storage bags can retain moisture content for a longer period of time compared to commonly used rice packaging bags.

General bacteria count measurement test of tap water

Test Summary

- Bags tested:

- Storage bags made of “Proguard”

- Nylon polyethylene bag

- Water used: Tap water (in Tokyo)

- Storage environment: Room temperature

Tap water was added to both bags and the number of general viable bacteria was measured at regular intervals.

Test Results

Change in general viable bacteria counts (viable counts) in tap water

| Sample | Test start date | 15 days later | 30 days later |

| “Proguard” storage bag | Not detected | Not detected | Not detected |

| Nylon polyethylene bag | Not detected | 5.4×10⁴ | 2.3×10⁵ |

It was confirmed that the general viable bacteria count did not increase after one month of storaging tap water in “Proguard” storage bags.

Technical Maturity and Introduction Results

The technical maturity of “Proguard” is evident through successful introductions in diverse applications. J-Chemical Corporation have introduced many products to government offices, hospitals, universities, etc. in Japan. The “Proguard” technology was used for deceased body storage during disasters, pandemics, and police-related cases. Over 50,000 bags have been shipped for storing bodies during the COVID-19 pandemic.

“Proguard” has also been utilised by flower production farmers to prolong freshness. By employing “Proguard” for storage, the flower farmers were able to stock fresh flowers for up to two weeks, enabling flexible shipping schedules aligned with market demand trends.

Information on patent related to this technology

Patent No. 4713669 (International Application No. Wo2008/139593)

Company Data

Company data

| Name | J-Chemical Corporation |

| Address | 3F Seiwa Bld. 3-31-1 Hongo Bunkyo-ku Tokyo Japan 113-0033 |

| Capital | 36.6 million yen (as of July 2023) |

| Contact person | Mr. Hidemichi TAKANASHI Tel: +81-3-3868-6100 E-mail:h-takanashi@j-chemical.jp |

| Number of employees | 5 (as of July, 2023) |

| Date of company foundation | April 1st, 2004 |

| The type of business | Manufacturing and sales of functional films and functional film processed products |

International operation

| Number of employees for international operation |

1 employee | |

|

Overseas offices |

City, Country | Name of Company (if applicable) |

| None | None | |

Modality of business transaction

Export of product

J-Chemical Corporation export and sell products manufactured in Japan.

Attachments

Schematic illustration of the technology

Not available

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Agribusiness Technologies : Food value chain