Anti-Viral and Anti-Bacterial

Anti-Viral and Anti-Bacterial  Material Synthesized from Ash

Material Synthesized from Ash

Waste Utilizing Ion Exchange Capacity

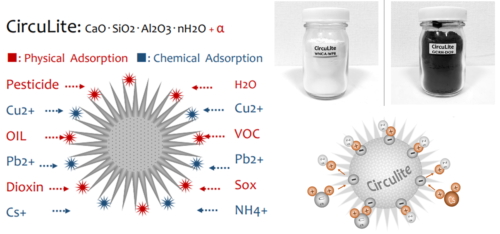

S ion Corporation has developed the multi-functional composite material called ‘CircuLite’ utilizing recyclable resources. CircuLite is a powdered material that owns the two main functions, a broad range of pore size distribution and ion exchange capacity. It can change chemical characteristics by replacing exchangeable ionic charge with some ANTIVIRAL metal that is suitable for purposes (see Fig. 1).

Fig. 1 Basic concept of CircuLite-AV

Fig. 1 Basic concept of CircuLite-AV

For example, ‘CircuLite-AV' is synthesized by replacing ionic charge with metal ion that has antibacterial and antivirus effects as well as less environmental impact. This inorganic multi-functional composite material with antibacterial and antivirus functions can produce a variety of secondary products by combining with other materials.

For instance, CircuLite-AV has been applied for the hygiene improvement; filters against air pollution and mask filters.

※Note: With regard to the manufacturing process, chemical and physical characteristics and general

applications of CircuLite, please refer to another webpage in the platform;

http://www.unido.or.jp/en/technology_db/6525/

Major Features and Advantages

- Inorganic functional powder material (CircuLite) equipped with antimicrobial/antiviral performance

- Add antimicrobial function on non-woven fabric and other filter material by a simple kneading of powder

- Utilized for personal protection equipment and home appliances.

- Ion Exchange Capacity provides a variety of antimicrobial function

- Porous structure captures pathogenic microbes

- Recycled material synthesized from biomass ash

Technology Data

Possible applications

Sion corporation has developed the technology that makes the powdered CircuLite-AV adhered to a surface of non-woven fabrics, which enables to achieve the practical application for antibacterial masks (see Fig. 2). Bacteria or virus in the air is trapped by non-woven fabrics and the air gets purified through the filtration process of non-woven fabrics and powdered CircuLite-AV. Particularly, since the infection of bacteria and virus tend to spread in a closed space, this mask can be used in places at the higher risk of infection such as hospitals to prevent group infections in a closed place.

Fig. 2 Face mask made of non-woven fabric with CircuLite-AV

Fig. 2 Face mask made of non-woven fabric with CircuLite-AV

Non-woven fabric with CircuLite-AV has been also applied for the air filter media in anti-bacterial air purifiers. Fig. 3 shows the image of photomicrography on surface of bellows-type air filter media.

Fig. 3 Surface of air filter media with CircuLite-AV

Fig. 3 Surface of air filter media with CircuLite-AV

Competitive advantage

Antibacterial and antivirus actions through filtration is generally challenging. Especially, a virus is a microparticle of which diameter (80-120 nm) is much smaller than that of bacteria (1000 nm) and can hardly be trapped by a conventional mask. However, as CircuLite has a broad range of pore size distribution and high water-holding capacity, as well as a stronger adherent effect compared to hydrophobic activated carbon elements, it helps the process of sterilization by debilitating and deterring the propagation of the microscopic virus or bacteria once adhered, through bactericidal metal such as Cu and Ag. It is considered a highly effective approach in developing countries in which the current medical environment tends to be still vulnerable.

Performance

1. Removal effect microbe

Non-woven fabric kneaded with CircuLite-AV have been tested for the removing capacity of Staphylococcus Aureus, which results showed the considerable performance.

|

*Testing Object: Staphylococcus Aureus – JIS K 3703-3:2008 |

Test Condition:

① Analysis Method: CNS 14774 T5017-2011 9.2, CNS 14775 5017 – 2003

② Test Area: 39.5 cm2

③ Average Particle Diameter: 2.8 μm

The graph below shows removal rate when passing the air containing Staphylococcus Aureus through the material. Removal rate of fungi was almost maintained around 99.5%, through the repetitive tests.

Fig. 4 Removal performance of non-woven fabric with CircuLite-AV-RGZ

Fig. 4 Removal performance of non-woven fabric with CircuLite-AV-RGZ

2. Removal effect of chemical

The other type of CircuLite-AV (product name: CircuLite-DO-RGN) was applied for the filter material in the anti-bacterial air purifier manufactured in Japan. The graph below illustrates high removal capacity of NH3 contained in aerosol which diameter is 2.5 micrometer or less. This removal effect was maintained even after two months.

Fig. 5 Removal rate of ammonia in aerosols of 2.5 micron or less

Fig. 5 Removal rate of ammonia in aerosols of 2.5 micron or less

3. Suppression of bacterial growth

A third-party organization in Japan conducted tests to measure the suppression effect of bacterial growth. Staphylococcus aureus/ MRSA were inoculated to a textile; to compare the multiplication in a raw textile and textile kneaded with CircuLite-AV-RGZ at the rate of 200g per square meter.

In the textile with CircuLite-AV-RGZ, the number of fungi decreased by 99% in 24 hours (Staphylococcus aureus), 3 hours (MRSA).

|

*Testing Object: Staphylococcus aureus ATCC 6538P |

Test Condition:

① Analysis Method: JIS L1902

Fig. 6 Suppression effect of bacterial growth (Staphylococcus aureus ATCC 6538P)

Fig. 6 Suppression effect of bacterial growth (Staphylococcus aureus ATCC 6538P) Fig. 7 Suppression effect of bacterial growth (MRSA IID 1677)

Fig. 7 Suppression effect of bacterial growth (MRSA IID 1677)

Technical maturity / Past record of introduction

Masks made by non-woven fabrics with powdered CircuLite-AV-RGZ has been produced and sold in Taiwan. Taiwan generally takes immediate and proper countermeasures since it has accumulated expertise of anti-bacterial/virus techniques and quarantine treatment through the experience of “SARS (Severe acute respiratory syndrome)” in 2003. The masks have been also sold in Hongkong and Guangdong (Shenzhen, etc.) in China.

The amount of CircuLite (powder) used in fabrics is estimated around 300 tons as of 2020.

Sion Corporation is planning to develop an air purification device by applying the filtration mechanism of masks and utilizing the harmful substance removing apparatus produced by Japanese deodorizing equipment manufacturers (with various delivery records but no antibacterial function), in places at higher risk of infection such as closed spaces in hospitals.

Information on patent related to this technology

Confidential

Company Data

| Name | Sion Corporation |

| Address | #101 1F Chateau AOYAMA, 5-4-51 Minami-Aoyama, Minato-ku, Tokyo, 107-0062 Japan |

| Capital | 10 million JPY (as of 15 November, 2019) |

| Contact person |

Mr. Shunsuke KUMAGAI (CTO) |

| Number of employees | 2 (as of 15 November, 2019) |

| Date of company foundation | Established: 22 March, 2016 |

| The type of business |

Category of Business: |

International operation

| Number of employees for international operation |

2 | |

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

First of all, we would like to conclude the consulting contract with clients to carry out Feasibility Study at customer’s expense to evaluate the possibility of utilization of the unused resources, no matter the cost. After that we would like to conclude the Fundamental Contract of Technology Transfer with clients.

Export of Product

CicuLite-AV-RGZ has been exported to Japan, Taiwan and China.

Licensing of patent

We normally expect our customers to establish processing plants. We can simply license our patents and know-how to customers by royalty payments. In addition, it could be difficult to develop recycling business by utilizing CircuLite unless customers become knowledgeable about its chemical and physical properties. If needed, it can be an option for us to have a ‘technical collaboration agreement’ with customers in order to seek for both environmental and agricultural application, in cooperation.

Attachments

Schematic illustration of the technology

Executive Summary:

We recycle, by our simple chemical process, from coal ash or biomass ash, such as agricultural strained lees, chaff, to make CircuLite, with functional modifications(*1): the functions of porous, ion exchange capacity, antibacterial. Its applications are for water treatment, soil improvement, filters against air pollution, for the hygiene improvement, or filters, mask as anti-bacterials including against COVID-19. We aim to save respectful people’s lives by improving sanitary environment and recovering the normal food chain in developing countries, people’s health, improve the resilience and immune system.

*1: Functional modifications: Carrying “chlorine deodorant” “an impregnation type of vegetative antibacterial grease” on the porous type, or “Ag, Cu, etc.” on the ion exchange function.

Our solution:

- The above-mentioned functional modifications will be utilized to improve sanitary environment, soil improvement, and more.

- The materials are coal ash or biomass ash, unless otherwise useless at some places; therefore, we believe our solution is environmentally and economically sustainable because disposals of coal ash or biomass ash cost from tens of thousand USD a year to millions of USD, locally produced and consumed: a closed loop. As mentioned, CircuLite has porous ion-exchange function, stabilizing indigenous bacteria, neutralizing chemical fertilizer, and improving soil for agriculture. Adsorbing heavy metals, preventing forwarding such poison to agriculture products. Thus, our solution can improve underground water, keep the creatures’ diversity.

- We can reduce incinerations and landfills by recycling coal ash and biomass ash, improving the sanitary environment. Currently, activated carbon or zeolite are main products to adsorb harmful physical/chemical substances. CircuLite is our next generation and eco-friendly products, tackling COVID-19. We aim to expand our business to different countries through the project this time.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Circular Economy (3R)

- Human Health Technologies : Public health