Next Generation Disinfectants and

Deodorants with New Manufacturing Technology for World Hygiene Management (Health Maintenance)

Deodorants with New Manufacturing Technology for World Hygiene Management (Health Maintenance)

T

o be thorough on hygiene management is now considerable challenges for both developed and developing countries. Increasing focus on safety, health, and sanitation drives demand for disinfectants each year. Terios-Tec Co., Ltd. and Parks Co., Ltd. provide the cutting-edge solution; the hypochlorous acid (HOCL) - based disinfectant 'Eva Water', which is generated by the patented buffer method.

Fig. 1 The image of hypochlorous acid disinfectant 'Eva Water'

Fig. 1 The image of hypochlorous acid disinfectant 'Eva Water'

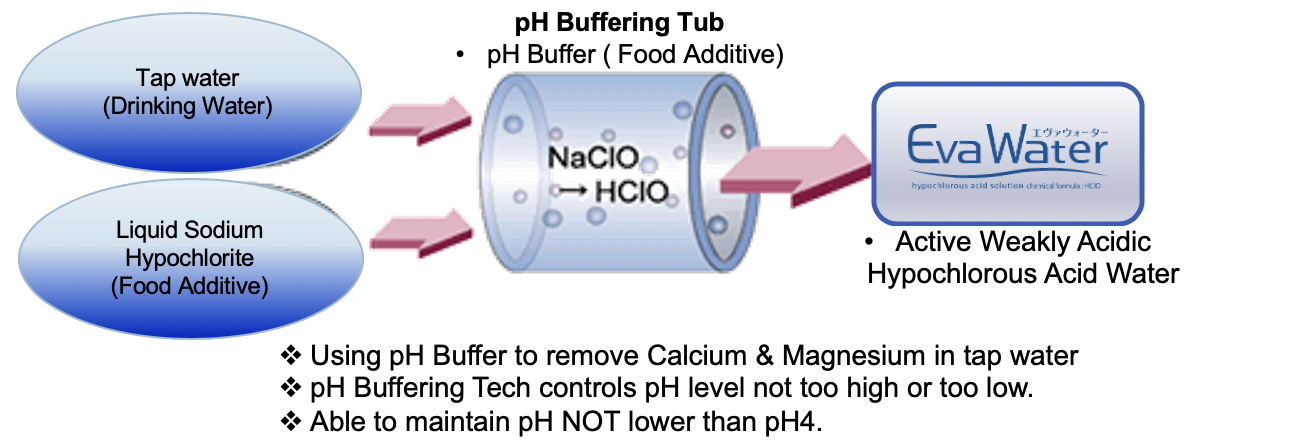

“Eva Water” has shown an increasing demand in Japan because it is recognized as a safe and effective sanitizer. “Eva Maker”, the manufacturing equipment using the patented buffer method as a part of operation system, is definitely necessary to keep our products’ quality. “Eva Pot” is a small-scale and instant generator for “Eva Water”. The key of buffer method is mainly ion-exchange reaction. This reaction naturally adjusts pH level around 4 to 6 and absorbs impurities of tap water (see Fig. 2).

Fig. 2 The concept of hypochlorous acid -based disinfectant ‘Eva Water’

Fig. 2 The concept of hypochlorous acid -based disinfectant ‘Eva Water’

‘Eva Water’ related products mentioned above are harmless for human, animal and environment. They can contribute to meeting globally growing demand of disinfectants and to improvement of world hygiene management system. Therefore, they can continuously make efforts to heighten global health and wellbeing awareness.

Major Features and Advantages

- Eva Maker provides high cost-efficiency of the entire system with minimum initial cost and initial preparation period.

- Eva Maker uses patented technology.

- The production engineering is easily learned by anyone irrespective of age and gender.

- Our technology makes it possible to generate products in large quantities* and in wide concentration range.

*Quantities of production depend on the supply of raw material water. - The producing processes and wastes are highly safe for both personnel and environment.

- Our produced products, Eva Water, are non-toxic and harmless to human, animals, and environment.

- The principal component of Eva Water, HOCL, is the same substance which our immune systems produce to kill infections in our bodies.

- Antiseptic effect of HOCL is about 80times more than one of Sodium hypochlorite.

- Long shelf life is warranted for a year by manufacturer.

Technology Data

Possible applications

Eva Maker, manufacturing equipment, is created to safely and easily generate Hypochlorous Acid (HOCL)water. It could be installed and activated in a short period once the ‘right’ place could be found. Eva Pot, generating pot, is also developed for the case of failure of Eva Maker’s installation. This portable pot could perform brilliantly in the field hospital. Their high simplicity could increase the supply of disinfectants in many developed countries. * In addition, the products by them are harmless and powerful HOCL disinfectants against germs, bacteria, and viruses. * (*It depends on raw material water’s quality if they could happen or not in either case.) At some hospitals and operating rooms in some developed countries, they still use ventilation as an infection control precaution even though sterilization is required. In these fields where requires high standard for sterilization, Eva Maker and Eva Pot could exert beneficial effects. They said alcohol-based sanitizers could inactivate SARS-CoV-2. In general, however, alcohol hardly eliminates most viruses, whereas Eva Water does (see Fig. 5).

Fig. 5 Comparison of Antibacterial Activity of Eva water and typical sanitizers

Fig. 5 Comparison of Antibacterial Activity of Eva water and typical sanitizers

We present some test results as follows.

Table 1. below shows 50ppm Eva Water inactivates most common viruses, such as E. coli, Salmonella, and spore-foaming bacteria which cannot be sanitized by boiling, in 1~3minutes.

Table 1 Comparison of Inactivation Rate between Eva Water & NaClO solution

Airborne viruses were mostly reduced by air disinfection with Eva Water in 10mins (see Fig. 6).

Fig. 6 Numbers of airborne viruses over time of air disinfection with Eva Water

Fig. 6 Numbers of airborne viruses over time of air disinfection with Eva Water

As a result of these tests, we are confident about international success of Eva Water as surface disinfectants not only in medical area, but also in food and beverage industry.

Competitive advantage

Electrolysis method, mixed solution method and buffer method are well known as generating methods for hypochlorous acid water.

Our buffer method provides high cost-efficiency of the entire system with minimum initial cost and initial preparation period. The manufacturing process is surprisingly simple for the buffer method. It only requires a few ingredients such as sodium hypochlorite (food additives’ quality), tap water and special buffer agent. In the generating cylinder, both sodium hypochlorite and water pass through buffer agent. By that, natural buffering action occurs to control and stabilize pH level around 4 to 6, as known as weak acid, and to absorbs impurities.

Fig. 7 Buffer method generating system (schematic diagram)

As a result, high purity hypochlorous acid water which maximizes all advantages of hypochlorite acid, HOCL, could be generated. Compared with other hypochlorous acid products, our products could last longer effects since they are pure enough to be stable. Other ones contain impurities and unstable, hence they must be used immediately once they are made.

Our producing process doesn’t generate emission or contamination of harmful chlorine gas which electrolysis method and mixed solution method commonly consider as an issue. In addition, the disposal of waste is easy to handle. Now, we are addressing an additional challenge of recycling used buffer agents.

Performance

Eva Maker

Production capacity by the company: 100 tonne/ year

Manufacturing cycle time for 100L: 5 minutes at the least※

Power source: AC 100W

The specification of Eva Maker will be alterable according to local power source.

Tap water: The quality meeting the 26 criteria based on Food Sanitation Act, Japan is desirable.

The quality is acceptable if it is appropriate for drinking.

Chemical properties of Eva Water

・pH:5.2-6.8

・Effective chlorine concentration: 50ppm or higher

・ORP: N/A

※It could be reduced by water pipe size. The discharge rate of products could be the same amount of water supply.

Technical maturity / Past record of introduction

The buffer method is qualified and maintained for 5 years. Our company has a track record in selling for 4 years. It has exceeded previous year’s sales since we ran the business. Eva Water has been used by domestic nursing homes, schools, banks and many others. We haven’t had any experience of foreign trade yet.

5 manufacturing plants including subcontract factories are located in Japan. Eva Maker would be handily installed and demonstrate high robustness and stable supply because it has a simple operation system which only needs proper tap water and power. The local research for the qualities of both tap water and power is essential. The education of hypochlorous acid disinfectants and their effects is also necessary in order to raise awareness about them and Eva Water because they appear low recognition compared to alcohol-based disinfectants and others.

Information on patent related to this technology

Patent Number: 5692657

Company Data

| Name | Terios-Tec Co., Ltd., and Parks Co., Ltd. |

| Address |

529 Nisso 18 Building, 3-7-18 Shin-Yokohama, Kohoku-Ku, Yokohama, 222-0033 Japan (Terios-Tec Co., Ltd.) |

| Capital |

3.9 million JPY (Terios-Tec Co., Ltd., as 10 of February 2020) |

| Contact person |

Mr. Yasuo OGATA (Parks Co., Ltd.) |

| Number of employees |

5 (Terios-Tec Co., Ltd., as of 1 August 2020) |

| Date of company foundation |

10 February 2020 (Terios-Tec Co., Ltd.) |

| The type of business |

Development, Planning, Marketing, and Foreign Trade of Environmental and Health products (Terios-Tec Co., Ltd.) |

International operation

| Number of employees for international operation |

5 |

|

| Overseas offices | City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

The manufacturing equipment would be exported from Japan, and manufacturing, marketing, and sales of products are entrusted to local partner company.

Export of product

Eva Pot including buffer agent and ingredients would be exported from Japan to local distributor/vendor for local sales. Deploying staffs is not required at site.

Attachments

Schematic illustration of the technology

Disposal instructions of ion exchange resins:

Collect used resins and put them in sealed containers, then reclaim or dispose at licensed waste disposal site. Disposal of contents/containers must be in accordance with local/regional/national/international regulation.

Regeneration method of used ion exchange resin has been under study.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Human Health Technologies : Public health