Provision of Long Storage

Capabilities by Maintaining

Freshness of Food Products

Ele Mag Lab. Co., Ltd. has successfully developed the world’s first comprehensive technology solution by combining freezing and refrigeration technology with high voltage and low current and leveraging our relay system that can be used in a wide range of applications.

Wi-Free (high voltage generator for maintaining freshness) can maintain freshness and store products in a wide area without freezing in the temperature range from 10℃ to -10℃, and the storage period can be greatly increased.

Fig. 1 Image of Wi-Free (left) and a refer container with Wi-Free (middle and right)

Major Features and Advantages

- Technology installed in a reefer container for the first time in the world

- Sterilization effect caused by ion wind and tiny amount of ozone generation

(It can also provide antioxidation, rotting prevention, and degradation prevention) - Suppressing water evaporation, reducing water activity, maintaining freshness, and promoting water absorption can be achieved by affecting the structuration of water through hydrogen bonding and the like caused by the fluctuation of water molecules, ions, polar groups, etc.

- Long term preservation of 1 month to 10 months is possible

- High performance and low price

Technology Data

Possible applications

There are great opportunities for food business in developing nations.

– Securing; to decrease rotting and maintain freshness to make stable supply of food possible

– Storing; to secure income by storing food for 1 to 10 months to export abroad

– Application; to produce high quality frozen food products by applying the technology to freezing food

Wi-Free has the following effects on food storage and plant preservation.

improve seed germination / shorten growth period / increase harvest / inhibit breeding of bacteria / improve water absorption and retention / enhance taste of food / prevent scale / prevent oxidation / purify water / Other

Similar products have been developed based on numerous literatures related to the effect of high voltage. One of them was made to maintain freshness a long term storage by formation of the electric field through applying high voltage to a low temperature range (10℃ to -10℃) and using electric field properties (molecular bonding, high voltage vibration, electric shock of moisture, etc.).

It was discovered that by applying high voltage to the interior of a freezer / refrigerator, an overcooled state can be created leading to long-term storage of food products.

However, there was a problem that one high voltage generator can only be effective for a small space, and therefore many high voltage generators can be necessary for large freezers / refrigerators. This meant it would take many costs to furnish the equipment. Therefore, high voltage generators have not become popular. Wi-Free was developed to resolve this issue.

Competitive advantage

If a power source is available, then a reefer container with a freshness maintaining feature needs to be purchased. It will normally cost 4 million JPY for a 40ft reefer container with a freshness maintaining feature. Operation cost would correspond to electricity cost. (Solar panel for the power source is preferable)

If it is a used reefer container, then there needs to be some engineering work for installing the machinery and insulating system.

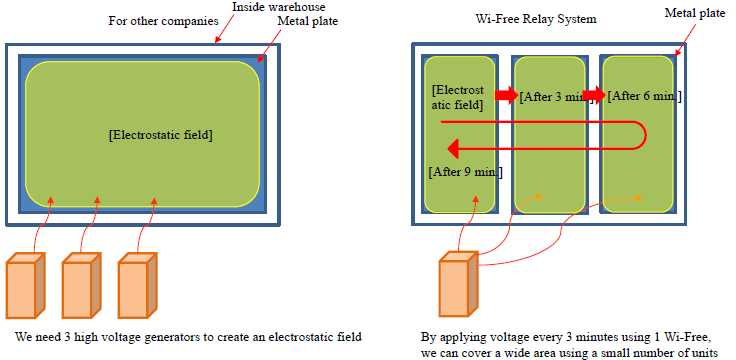

1) When compared to similar products, there is a limit to the area that can be covered using one system core, so that other companies can only cover 6 m2. In contrast, we can expand this capability by up to eight times through using our relay system.

Fig. 2 Scheme of the relay system

Fig. 2 Scheme of the relay system

2) Structure of insulation inside the storage is different from conventional products.

Other companies use a framing that covers the four sides of the storage interior using aluminum plates, wherein a 60 mm insulator (made of ceramics) is installed at a regular interval on the outside of the aluminum plate framing covering the interior. However, we provide insulation by directly attaching an insulating resin to the wall surface and installing 20 mm resin insulators on the aluminum plate floor.

Fig. 3 Illustration of insulation material and aluminum panel

Fig. 3 Illustration of insulation material and aluminum panel

3) All companies have an applied voltage of 3500 or greater. As for the polar plates such as aluminum plates, other companies cover the four sides using polar plates while we only install them on the floor surface.

4) Regarding the supply price of 20 ft reefer container, other companies cost JPY 5 million or greater, while our price is JPY 3.5 million or less.

5) Other companies do not manufacture 40 ft containers, so there are no competitors.

The supply price of our 40 ft reefer container is 4 million JPY or less (increase in additional material cost).

Performance

Specification

1) An electric field is formed by using the direct voltage application method.

2) Weight: 15kg (except refer container)

3) Voltage output: Max. 3500 V

4) Current output: Max. 5 mA

5) Voltage input: 100 V ~ 240 V

6) Frequency: 50 Hz ~ 200 Hz

7) Operating temperature range: 10℃ ~ -10℃

8) Controlled by a safety mechanism: using a limiter

9) Power consumption: 30 W (except the reefer container)

Table1 Standard preservation term of foods in Wi-Free

Technical maturity / Past record of introduction

1. Domestic

– 20 units were installed to railway containers of Japan Freight Railway South-Kanto Logistics Company by using subsidies from the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) for low temperature transportation, in 2018.

– Others (52 units were installed using subsidies from MLIT) in 2018

– Wi-Free Railway Transport project

Wi-Free Rail Transport Test Summary

Wi-Free Rail Transport Test Report

※The word of ‘HYOKAN SO-KO’ in the document above is the old name of Wi-Free.

2. Overseas

70 units were installed to containers owned by Hoàng Châu company in Vietnam, using JCM (Joint Credit Management) subsidies from the Ministry of Environment, Japan: Environmental conservation project by modal shift in 2019.

Sales mentioned above and production of the completed products at Taicang CIMC has contributed to stabilizing supply.

Information on patent related to this technology

Patents have been applied in Japan.

Company Data

| Name | Ele Mag Lab. Co.,Ltd |

| Address | #304 quarant1966, 1-4-10 Jiyugaoka, Meguro-ku, Tokyo, Japan |

| Capital | 10 million JPY (as of 20 April, 2020) |

| Contact person |

Mr. Kouichi OMURA |

| Number of employees | 7(as of 20 April, 2020) |

| Date of company foundation | 19 August, 2016 |

| The type of business |

Manufacturing and sales |

International operation

| Number of employees for international operation |

Sales representative: 1 Local staff: 2 |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| Hanoi, Vietnam | O’s&Tec VIETNAM.,JSC | |

Modality of business transaction

Partnership

Based on a partnership agreement (exclusive sales), we export the completed container having the freshness maintaining feature while the partner company conducts sales.

Licensing of patent

Business model transfer and licensing of patent

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Agribusiness Technologies : Food value chain