Making Sustainable Ethanol

and Feed from Biomass

with NO Waste

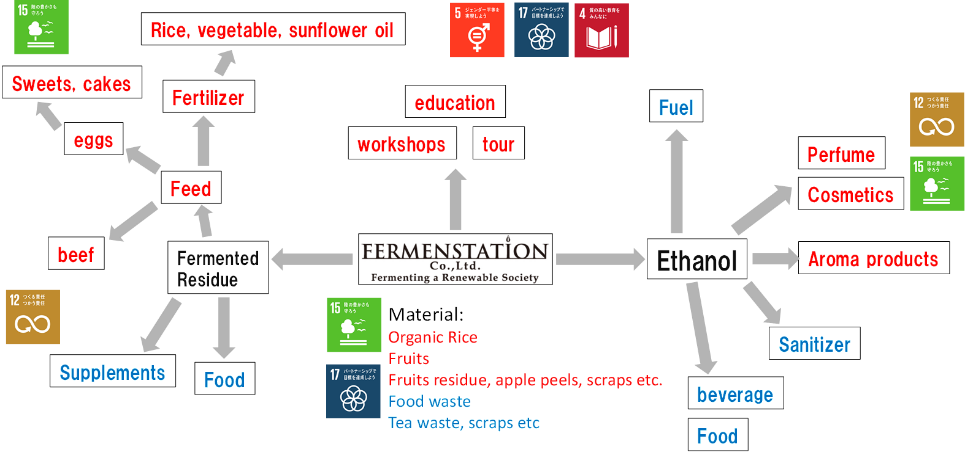

O ur proprietary fermentation system allows for manufacturing ethanol utilizing a variety of biomass not only limited to high sugar content materials such as corn and sugar cane. Utilizing our technology, we can turn what was raw waste (such as food scraps from food factories) into ethanol which can be used for a variety of purposes.

Fig. 1 Scheme of business operated by Fermenstation

Fig. 1 Scheme of business operated by Fermenstation

Company introduction video:

NHK World documenbtary (URL is valid until December 2020):

https://www3.nhk.or.jp/nhkworld/en/ondemand/video/2042091/

Major Features and Advantages

- Ability to produce ethanol in small scale for a wide range of biomass (rice, fruits scraps, apple peels, banana peels etc )

- Our integrated fermentation – distilling process allows for a compact ethanol production system

- Value addition (see Fig. 2)

- No waste coming from the system as the residue is used as feed for hen, cattle, pigs etc. (see Fig. 3)

Fig. 2 Example of the organic products (left: aroma spray made of ethanol, right: soap made from

Fig. 2 Example of the organic products (left: aroma spray made of ethanol, right: soap made from

fermentation residue)

Fig. 3 Rice fermentation residue (left) and processed residue for animal feed (right)

Fig. 3 Rice fermentation residue (left) and processed residue for animal feed (right)

Technology Data

Possible applications

Our integrated fermentation/distilling production system allows for turning food scraps into ethanol thus creating new value from what was once considered waste. Ethanol has a wide applicability from fuel use to antiseptics to cosmetics which has the potential to create a new industry and supply chain.

Also, the fermented residue is rich in many functional ingredients that also has potential uses for animal feed to functional ingredients for cosmetics.

Competitive advantage

- Although we have no published IP and trade mark, our technology is imbedded with significant know how and trade secrets

- Our integrated fermentation/distilling production system does not require significant upfront investment. A normal system would need at least $500,000 upfront but ours require 40% to 50% less. For a small-scale system, it would be around $100,000.

- Since the fermentation and distilling devices are in one package, the system itself is compact in size and mobility is high, thus allowing for producing ethanol onsite where the biomass lies. Considering the costs entailed to transport the biomass, this onsite production is a significant low cost feature.

- Operation is relatively easy and with initial training, we believe local staff would be able to run the production facility and conduct maintenance.

The fermented residue from our process has also many features of which has the potential to be value-added ingredients. Depending on the biomass, this could be animal feed with high amino acid content or functional ingredients for cosmetics.

Performance

Material: rice, wheat, food scraps (from food and beverage companies such as apple scraps, banana scraps, tea grains etc)

Fermentation and Distillation: 1-2 weeks

Amount depends on the size of equipment: from 50kg over

Technical maturity / Past record of introduction

We have conducted experiments with more than 10 types of biomass, from rice for non-human consumption, vegetable and fruit waste, all successfully converting into ethanol. We have a rice ethanol production facility in Japan which is already in commercial stage and can be considered a conventional stable technology. There ethanol derived products (aroma products and cosmetics) are sold in major department stores and cosmetic stores in Japan.

Fermenstation conducted the demonstration experiment for fermentation of cassava in Thailand. The company has a plan to establish local-based food waste collection and fermentation system in developing countries.

Information on patent related to this technology

N/A

Company Data

| Name | Fermenstation Co., Ltd. |

| Address | Center of Garage Room 8, 1-16-3, Yokokawa, Sumida, Tokyo, Japan |

| Capital | Undisclosed |

| Contact person |

Ms. Lina (SAKAI) WATANABE |

| Number of employees | 8 (as of September 2019) |

| Date of company foundation | July 7, 2009 |

| The type of business |

Ethanol production and consultation |

International operation

| Number of employees for international operation |

3 | |

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Partnership

We look to collaborate with a local partner that has the potential to provide stable source of biomass. Fermenstation will provide technology support including tech-transfer of our production system and to produce ethanol using locally sourced biomass. Providing an exit, or sales channel, for the ethanol is key and we look forward to establishing product development and sales collaborations with the partner as well.

Attachments

Schematic illustration of the technology

- Articles in English:

・NHK World documentary “Rising” https://www3.nhk.or.jp/nhkworld/en/ondemand/video/2042091/

・People of Iwate (2018)

https://people-of-iwate.tumblr.com/post/172555946246/lina-sakai-of-oshu-city-originally-from-tokyo

・Visit Iwate https://visitiwate.com/en/article/4940

・Government online https://www.gov-online.go.jp/eng/publicity/book/hlj/html/201511/201511_11_en.html

・Beauty Tech in English

https://medium.com/beautytech-jp/the-story-behind-this-rare-100-circular-bioethanol-from-japan-eef6456c9176

・Apt introduction of Fermenstation https://apt-women.tokyo/en/program/participant/participant05.html

- Articles in Chinese:

・Cifnews (2015) http://www.cifnews.com/Article/15359

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Circular Economy (3R)

- Agribusiness Technologies : Food value chain