Stable and Regenerable

Ti-based TiO2 Photocatalyst

of Multiple Application for Environment

Y

ield Co., Ltd. has developed a multi-functional material “Titanystar” which decomposes harmful organic compounds by the photocatalytic technology, and it can be effectively applied to cleaning of undrinkable water into safe drinkable water. This photocatalytic reaction derives from a uniform layer of titanium dioxide (TiO2) generated upon metal titanium, by the special technology of surface oxidation.

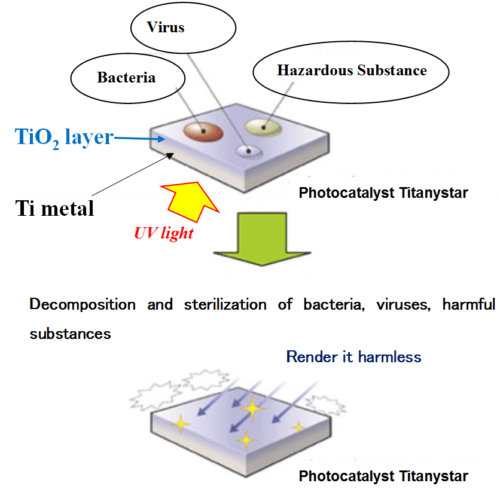

The photocatalytic mechanism was invented in Japan has been an excellent environmental purification method which decomposes and removes most of harmful substances simply by receiving ultraviolet rays. (See Fig. 2) As photocatalyst has been getting more excellent abilities to decompose and remove almost all harmful substances, disinfectant for water such as chlorine and ozone becomes unnecessary in water treatment process. Therefore, chemical-free and clean drinking water can be provided.

Fig. 1 Photocatalyst Titanystar

Fig. 2 Conceptual diagram of harmful substance decomposition by photocatalytic mechanism

Fig. 2 Conceptual diagram of harmful substance decomposition by photocatalytic mechanism

Major Features and Advantages

- High performance because there is no impurity in the photocatalytic layer.

- Because the photocatalytic layer is quite durable, it can be used semi-permanently.

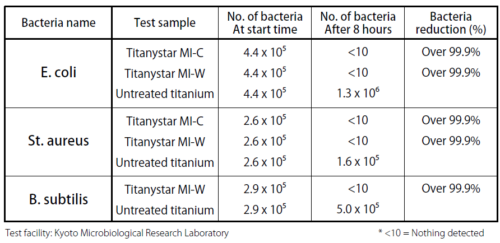

- Bacteria and viruses can be sterilized and removed relatively easily. (see Table 1)

- Titanystar is excellent in maintainablity.

- Since ultraviolet rays are contained in sunlight, it can be used without electric power.

- Titanystar was certified by the Ministry of Defense of Japan for water purification technology, “the Best Innovator Award for the Security Water Project of the Defense Technology Symposium 2014 organized by the Ministry of Defense on 12th November 2014”.

Table 1 Bactericidal effect on Titanium oxide

Examination date: May 2012 Titanystar MI-W is a gas decomposition type, Titanystar MI-C is a water purification type. Inspected by: Kyoto Biseibutsu Kenkyusho (Kyoto Microbiological Research Laboratory)

Examination date: May 2012 Titanystar MI-W is a gas decomposition type, Titanystar MI-C is a water purification type. Inspected by: Kyoto Biseibutsu Kenkyusho (Kyoto Microbiological Research Laboratory)

Untreated titanium (metal titanium) itself does not have any photocatalytic function. This table confirms that Titanystar certainly obtains photocatalytic function, by oxidizing the surface of untreated titanium. Regarding the comparison of photocatalytic performance between Titanystar and other TiO2 coatings, please inquire to Yield Co., Ltd.

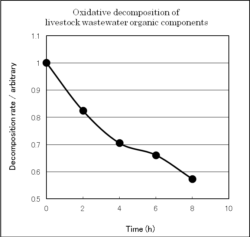

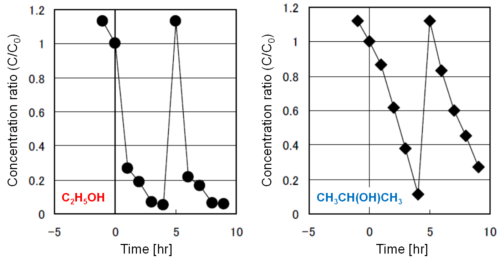

In addition, Photocatalyst Titanystar shows good performance for oxidative decomposition of organic components. Fig. 3 illustrates that more than 40% of organic compounds in wastewater are decomposed within 8hours.

Fig 3. Decomposition effect of organic substances in water

Fig 3. Decomposition effect of organic substances in water

Inspected by: Kyoto Prefectural Technology Center for Small and Medium Enterprises. Examination date: 2008 May

Technology Data

Possible Applications

< Inadequacies of electric infrastructure in depopulated settlement >

When the photocatalyst receives ultraviolet light on its surface, it shows effects on contaminants such as bacteria and viruses. In developing countries, especially in depopulated settlements, water purification efficiency is somewhat inadequate due to lack of electric infrastructure. However, utilizing ultraviolet rays contained in solar rays which activate the photocatalytic function enables water purification without electricity supply and provision of drinking water.

< Infrastructure maintenance area and urban area >

In the infrastructure maintenance areas and urban areas, we manufacture water purification equipment with photocatalyst using ultraviolet lamp to purify contaminated water efficiently. Water purification equipment will consist of various types of UV source and other mechanical systems, which can be supplied from small-scale settlements in a densely populated areas without excess or deficiency.

In the occurrence of a natural disaster, it is possible to provide safe drinking water as a fresh water generator for disaster recovery.

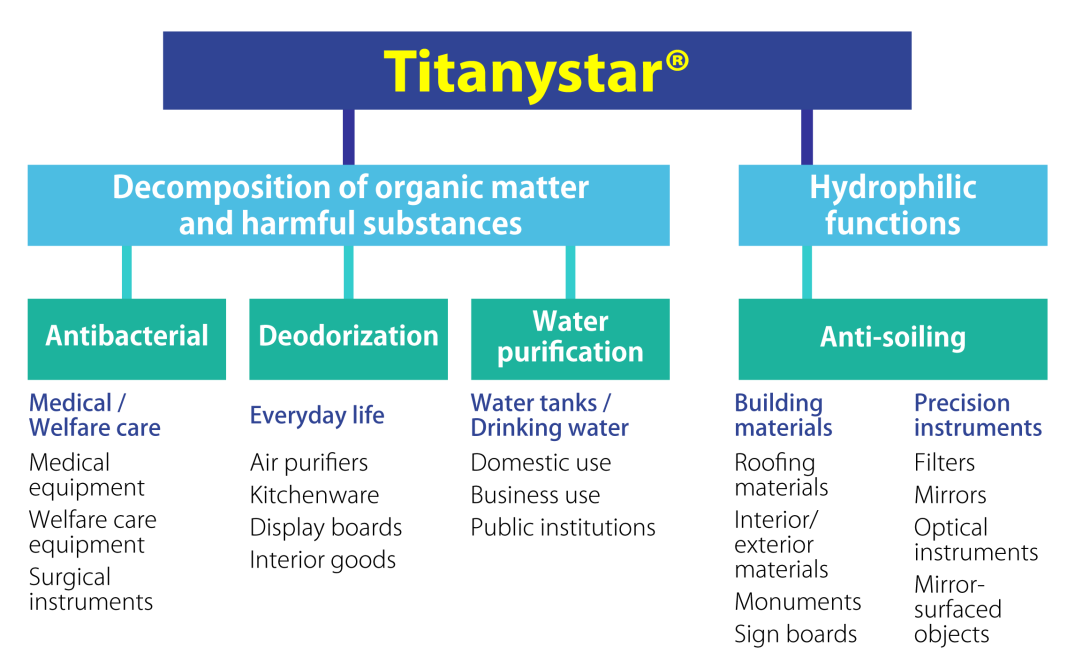

Other than water purification, Titanystar can be applied for wide variety of purposes. (See Fig. 4)

Fig. 4 Various purposes of Photocatalyst Titanystar

Fig. 4 Various purposes of Photocatalyst Titanystar

Competitive Advantage

It is an environment purification technology with high reliability from Japan, and only Titanystar can purify wastewater among commercial photocatalytic products. We have a lot of experiences of installation both in domestic areas and overseas. Moreover, we received “the Best Innovator Award for the Security Water Project of the Defense Technology Symposium 2014” organized by the Ministry of Defense, on 12th November 2014.

As mentioned above, almost all harmful substances can be decomposed and removed. Since reaction takes place only by exposure to ultraviolet rays, large-scale electric power is unnecessary. Ultraviolet rays in sunlight can be available without power.

Since it is a catalyst, water purification reaction can be continued. It has stronger purification performance than chlorine, ozone and hydrogen peroxide. There is no complicated operation like separation membrane. Operating costs are almost unnecessary, only initial costs are needed.

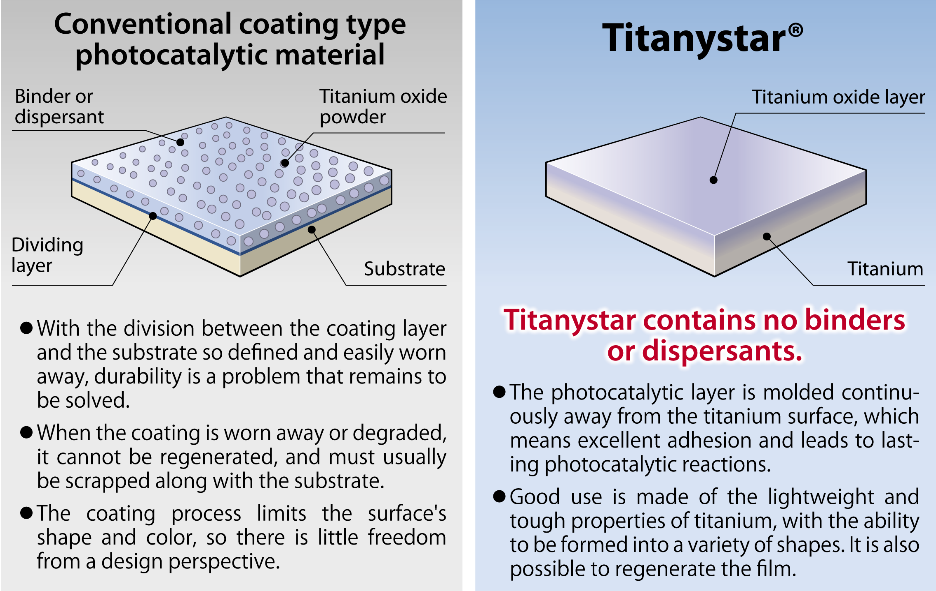

TiO2 layer in Titanystar has higher durability against physical contact compared to standard TiO2 coatings, which can be gradually peeled from base materials due to degradation of adhesive properties. Moreover, even if TiO2 layer in Titanystar have a damage, it can be regenerated by the surface oxidation. (See Fig. 5)

Fig. 5 Difference between Photocatalyst Titanystar and general photocatalyst

Fig. 5 Difference between Photocatalyst Titanystar and general photocatalyst

Performance

Decomposition of organic matter

Titanystar actually shows stable performance of organic matter decomposition. Fig. 6 shows first and second reaction of the decomposition cycle test. Comparing first with second reaction, there is almost no deterioration in decreasing trend of C/C0 ratio. (C0: initial concentration, C: actual concentration)

Fig. 6 Cycle test of decomposition (left: ethanol, right: isopropyl alcohol)

Fig. 6 Cycle test of decomposition (left: ethanol, right: isopropyl alcohol)

Practical case of water purification

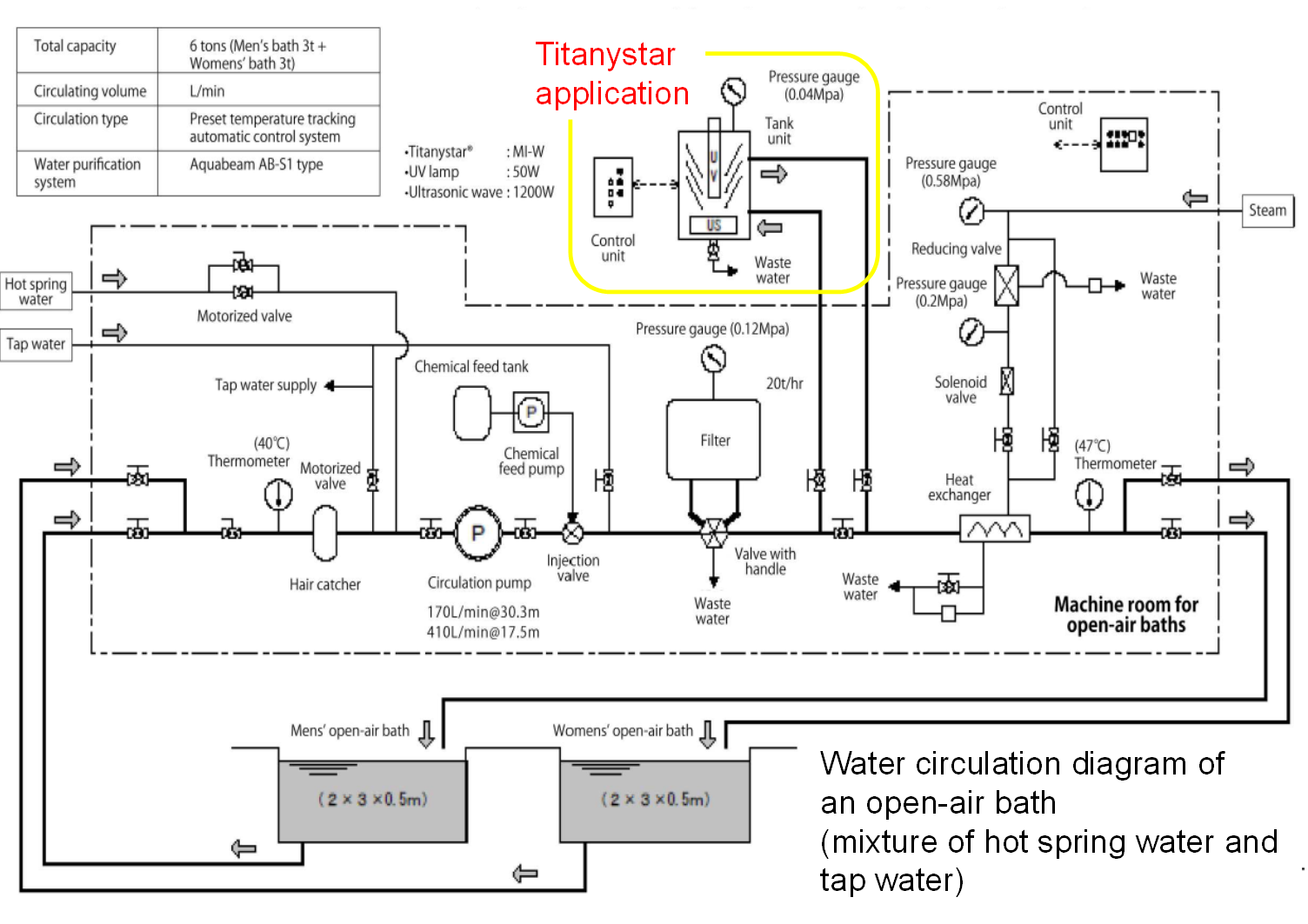

After the introduction of the Photocatalyst Titanystar purification device, there is no generation of general bacteria or legionella bacteria occurring in natural hot springs, and it maintains safety and sanitation.

Fig. 7 illustrates the water circulation diagram including water purification by Titanystar, installed to the hot spring facility in japan.

Fig. 7 The application exmaple of Titanystar (water treatement in an open-air bath)

Fig. 7 The application exmaple of Titanystar (water treatement in an open-air bath)

Technical maturity / Past record of introduction

・Number of sales in Japan

From 2000, cumulative total about 30,000 units or more

・Overseas sales

From 2004, cumulative total of about 2,000 units

Exports to France, UK, Russia, New Zealand, Singapore, Malaysia, India, Taiwan.

Information on patent related to this technology

Japan Patent No.3370290

US Patent No.6344127

Company Data

| Name | Yield Co., Ltd. |

| Address | 998-22 Suenokuchi-cho, Kamigyo-ku, Kyoto, 602-8382 Japan |

| Capital | 3,000,000 yen (as of 13th February, 2019) |

| Contact person |

Mr. Yoshihisa ITOH |

| Number of employees | 5 (as of 13th February, 2019) |

| Date of company foundation | 3rd April, 2000 |

| Type of business |

Manufacture and sale of chemical industrial products |

Corporate website: http://www.yield-kyoto.com/en/

International operation

| Number of employees for international operation |

N/A |

|

| Overseas offices |

City, Country | Name of Company (if applicable) |

| N/A | N/A | |

Modality of business transaction

Direct Investment

The last stage

Based on the results of the first and second stages, we want to invest directly in non-expanding countries and start up business based on our technology from the scratch.

Partnership

First stage

Initially we would like to contract our existing patented technology with existing local companies and start business operations.

Licensing of patent

Second stage

After partnership agreement, we would like to license according to circumstances, to locally producers and expand our business.

Attachments

Schematic illustration of the technology

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control

- Human Health Technologies : Public health