Multifunctional Coating Agent

Multifunctional Coating Agent

Based on Nanotechnology

K okusaikan Corporation Japan and allied companies offer a multifunctional coating agent based on nanotechnology. The coating agent can be mixed with organic or inorganic base materials and brushed like regular paint on windows, roofs, walls, tents, and other industrial products. A thin transparent coating can be easily created without a primer. The agent provides better insulation, heat protection, dust repellent, water repellent, and antibacterial functions to meet the product requirements. Application of this agent will add energy saving and cost-efficient properties to a variety of products.

Major Features and Advantages

I. Insulation & Heat Protection

To create heat protective paint, the coating agent is mixed with regular paint at a ratio of 1:9. When the agent is applied to items such as roofs, gas tanks, and oil tanks, their temperature falls by over 10℃. Application of this agent protects buildings, houses, items placed in containers, warehouses, and factories, and passengers on public transportation from heat. The agent is also used to coat the surface of airport runways made of tarmac so that it keeps the tarmac firm in high temperature.

II. Dust Repellent

Dust on solar panels may lower their power generation by 15%. If the agent is applied on solar panels, its antistatic function will keep them clean and free from dust and maintain their performance. Visible light penetration function added to this coating enables light to be collected more efficiently and increases power generation by 1 to 3%. The agent will reduce frictions and save on fuel consumption when applied on aircraft. Application of the agent to outdoor infrared sensors on train doors will also keep dust away and maintain stable operation.

III. Water Repellent

The agent is water repellent. When it is applied on mirror surfaces, it prevents condensation (formation of water droplets). Water repellent surfaces prevent accumulation of dust. Because the agent is transparent, vision through painted mirrors is not affected. Therefore, it is perfect for mirrors of vehicles, trains and other transportations.

IV. Antibacterial

The agent provides antibacterial function when it is applied on toilets and tiled floors in bathrooms. It is especially useful in food processing factories as it prevents harmful bacteria to stay and grow on tile surfaces. Application of this agent maintains good hygiene.

For the last three years, Japan Railways has been using this agent on their trains. The agent is highly appreciated as it protects their cars from dust and condensation, and passengers from excessive heat.

Technology Data

Conceivable applications

Heat cutting function added to local paint makes: Insulating paint which can be brushed on roofs, walls, tents, etc.

This product will reduce excessive temperature stress for people in buildings, households, factories will protect crops in (agriculture) warehouses, goods in containers, and passengers in buses, etc.

Dust repelling function (anti-static property) coated on painted surfaces will protect the heat cutting function and other functions as well from deterioration due to the force of elements (sunshine, etc.) or accumulation of dust, dirt or else that, otherwise blocs the function.

- This anti-static protection keeps solar panels clean & free from dust to maintain performance levels in power generation.

- Visible light penetration function added to this coating will increase power generation performance.

- Super hydrophilic function added will control condensation (droplets) on mirror surfaces that also attracts dust & affects vision in traffic mirrors.

- Hygienic function coated on toilets / W.C.’s bathrooms, tiled floors, etc. will provide anti bacteria protection also useful in food processing.

- Anti-static function coated on aircraft will reduce friction & save on fuel consumption.

- Heat cutting function mixed with airstrip surfaces will keep the tarmac firm in high temperatures.

The field for actual applications is immense. For conceivable applications the potential is even wider.

Tell us what you need. We’ll answer with the appropriate function.

Competitive advantage

Our products do not have any competition. There are no such manufacturing / production systems available.

Some finished products using this technology are on the market.

(but prices are prohibitively high)

The advantage of producing is unmatched. Full information will be provided with records.

Our mode of business is technology transfer to create a successful local industry.

We want to be part of our Partner’s success story.

First we provide the Heat cutting function that our Partner will mix with his local paint. (Then various functions follow).

The function carrying “Binder” or inorganic coating will be diluted with local water / alcohol, as soon as the Partner’s technical progress permits

Many of the functions or ingredients / contents will be replaced with materials available from sources close to our Partner’s area (less expensive). Any item, function or ingredient found favorable in terms of quality, price or else will be adopted. The advantage of this system is that it is composed of parts that can be changed at will to obtain a superior product. The Partner joins us in every way from testing what he produces with this technology to comparing with what is presently on the market.

Performance

・Heat cutting paint will bring down temperature by over 10℃ on roofs, gas / oil tanks & others.

・On solar panels visible light penetration function will up performance by 1 – 3 %.

・While anti-static function will prevent decrease in performance that often decreases by 15%.

・Outdoor infrared sensors are kept free from dust with anti-static function to maintain stable operation of train doors &

various automatic performances.

・In operation with Japan Railways for the past 3 years.

・Reports are available for several items & inspection tours regularly conducted with performance data provided.

※Notes

From October 2018, nanobubbles are introduced to coating materials to improve its functions.

Nano-Science Laboratory Corporation and Japan Nano Coat Co., Ltd. conducted joint research on the application of nano-sized bubbles(air or inactive gas) in coating agents to improve the adhesiveness and the dispersivity of silica-based particles in the agents.

As a result of this technical development, coatings with nanobubbles are able to have longer product life* than conventional coatings. Adhesiveness also gets better. In this point, The two companies are still evaluating the effectiveness by monitoring the used products.

*product life: duration of the multi-function(heat protection, insulation, water repellent, etc.)

Technical maturity / Past record of introduction

Above mentioned items are conventional with operation records for the past 4~5 years. Condensation control (Hydrophilic function) has kept clear vision on traffic mirrors for the past 3 years.

Conceivable risk

The greatest risk lies in the “lack of discipline” or lack of coordination in production process.

We conduct tests at every major step both in Tokyo (for counterparts , including embassies to follow) & at the Partner’s Headquarters according to reasonably established schedules to keep.

Normal exchanges of information on processes & results, are vital.

Information on patent related to this technology

Information is available according to field of interest.

There is a vast pool of Patents to choose from & the number increases yearly by 4~7.

Company Data

| Name |

Representative Company: Allied Company: Allied Company: Allied Company: Allied Company: |

| Address |

Kokusaikan Corporation Tokyo Office Japan Nano Coat Co., Ltd. Miyako Roller Co., Ltd. Main factory ef-initials Co., Ltd. Nano-Science Laboratory Corporation |

| Capital |

Kokusaikan Corporation Japan : JPY 10,000,000 |

| Contact person |

Kokusaikan Corporation Japan: Ms. Setsuko TIMUR |

| Number of employees |

Kokusaikan : 7 |

| Date of company foundation |

Kokusaikan : June 15, 1993 |

| The type of business |

Kokusaikan Corporation Japan Japan Nano Coat Co., Ltd. Miyako Roller Co. Ltd ef-initials Co., Ltd. Nano-Science Laboratory Corporation |

International operation

| Number of employees for international operation (including overseas operation, if any) |

Overseas Offices |

|

| Overseas offices* | City , Country | Name of company |

| Hong Kong China | JNC INTERNATIONAL TRADING LTD. | |

* Overseas offices of alliance members and/or consortium members are also accepted.

Modality of business transaction

Partnership

Technology Transfer to gradually create self-sufficient local industry, Provide technical know-how & some basic material to use with local resources for production. Introduce investment schemes & markets for those products.

(1)- START: According to a Basic Agreement with a local company we provide the know how technical assistance & part of the materials to be used (mix) with local resources in order to achieve / manufacture the finished product.

(2)- GRADUAL PROCESS: Elementary items, such as insulation (heat cutting paint) are mastered & finished products manufactured first before moving to more advanced items. (i.e. nanotechnology multifunction coatings ).

(3)- Hand work applications are mastered first before moving to equipment usage & mass production.

Export of product

Nanotechnology Multifunction coatings (dirt repellent function, super hydrophilic, insecticidal, hygienic, etc.) will at the Start be exported from Japan.

As mastery of the application technique improves dilution/mixing with local materials / resources (alcohol / water, etc.) will start. Where mass production starts with the usage of equipment / machinery local assembly of lines will be encouraged.

Licensing of patent

Licensing of patent is considered to be one of the main pillars of our mode of business to create: local self- sufficient industry & promote development in the long run.

Attachments

Schematic illustration of the technology

Order of production

STEP – 1 Hand work

STEP – 2 Equipment usage (mass production)

STEP -1 Hand work (no equipment)

Heat cutting function is provided (10 % material) to mix with Local Paint ( 90 % ) & create heat cutting insulating paint.

A-RESULTS: Paint reduces Temperature by 10 ℃.

Applications

Buildings, Households, Tents, Factories, Warehouses, Transport, Containers, etc.

B- PROTECTIVE FUNCTION

Antistatic property coated on painted surface will REPEL dirt, foreign elements to prevent accumulation of dust on painted surfaces & deterioration of heat cutting function.

The Video

Shows how the antistatic protective function coated on a solar panel repels dirt (powder) to maintain light absorption & power generation performance INTACT.

C- NEEDED FUNCTIONS are carried in the supplied nanotech coat to be simply applied on the desired surface.

Applications

Civil engineering & industrial use : from airstrips, traffic mirrors, water, gas, petrol tanks,

to electronics, computers, screens, lighting LED, sensors to food processing, hygiene , etc. Various

functions are CUSTOMIZED to meet NEEDS, designed & provided in a nutshell of nanotechnology

coating ready to be applied in a stroke of the brush.

Photo-1

Antistatic dirt / dust (powder) repelling function

Left side Not coated: (powder sticks)

Right side Coated: (powder does not stick)

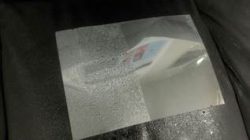

Photo -2

Super hydrophilic function. No mist clear vision function

Left side Not coated: (rain) Water makes

surface misty.

Right side Coated : (rain) Water spread

evenly. No mist. Surface clear.

Machine characteristics.

1)-Uniform coating function (additional).

2)-Customized functions (according to needs).

3)-Adjustment function to thick /thin coatings.

4)-Rollers with super hydrophilic function (uniform layer) .

5)-Antistatic function (prevents dust sticking to products.

STEP -2 Usage of equipment

Step 2 involves the usage of the most advanced equipment / machinery

adopted in all phases of industrial development & mass production from

print boards, films & electronics to heavy industries, plating & other

applied technologies.

Please see the following page;

http://www.miyako-roller.co.jp/englishsite/index.html

N.B

After the first step of Hand work is mastered, the second step of using equipment is approached gradually to enable local assembly to full production of the machines.

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Energy Technologies : Energy saving and energy storage

- Human Health Technologies : Public health