Elbic Series: Microbial Wastewater

Treatment Solutions for

Food Industry

In 1996, Hazard Analysis and Critical Control Points (HACCP) system was introduced in Japan. In this system, each step of food production process is scientifically analyzed for possible hazards to ensure product safety. This system, however, has increased the amount of detergents and pesticides used during food processing. The excessive amount of chemicals in wastewater resulted in weakening and killing of microbes, which decompose organic matters into carbon dioxide, water, and ammonia in the following activated sludge process. To address this issue, HINODE SANGYO Co., Ltd. has developed multiple solutions that enhance growth and use of microbes.

Major Features and Advantages

I. ElbicNEOTM

ElbicNEOTM is an agent that provides Bacillus subtilis strains to wastewater. Wastewater from food or beverage factories contains organic matters, detergents, pesticides, and rinse water. Microbes in this wastewater are unable to survive due to lack of dissolved oxygen. Organic matters are, therefore, left untreated. The microbes in ElbicNEOTM (ElbicNEO microbes) can survive in this harsh environment by forming spores to resist chemicals, heat, and pH. They grow fast and double their number every 20 minutes. Continuous injection of ElbicNEOTM allows stable and consistent treatment of wastewater, regardless of its characteristics. ElbicNEO microbes decompose proteins, lipids, and carbohydrates and inhibit the growth of coliforms. ElbicNEOTM is effective in wastewater of low oxygen concentration.

ElbicNEOTM is an agent that provides Bacillus subtilis strains to wastewater. Wastewater from food or beverage factories contains organic matters, detergents, pesticides, and rinse water. Microbes in this wastewater are unable to survive due to lack of dissolved oxygen. Organic matters are, therefore, left untreated. The microbes in ElbicNEOTM (ElbicNEO microbes) can survive in this harsh environment by forming spores to resist chemicals, heat, and pH. They grow fast and double their number every 20 minutes. Continuous injection of ElbicNEOTM allows stable and consistent treatment of wastewater, regardless of its characteristics. ElbicNEO microbes decompose proteins, lipids, and carbohydrates and inhibit the growth of coliforms. ElbicNEOTM is effective in wastewater of low oxygen concentration.

II. ElbicNEO IncubatorTM

The ElbicNEO microbes can be incubated in a fully automated device called ElbicNEO IncubatorTM. This incubator provides optimal conditions for the microbes to grow. It requires clean tap water to operate and increases the microbial population by 25 times. Growing ElbicNEOTM microbes in this incubator will significantly reduce the cost to purchase the strains. The microbes are automatically injected into wastewater treatment plants. ElbicNEO IncubatorTM is especially useful in treating wastewater containing a large amount of fat and chemicals because it can continuously provide a lot of microbes. For this reason, the incubator has been installed in dairy and other food processing factories, which extensively produce dairy cream and shortening.

The ElbicNEO microbes can be incubated in a fully automated device called ElbicNEO IncubatorTM. This incubator provides optimal conditions for the microbes to grow. It requires clean tap water to operate and increases the microbial population by 25 times. Growing ElbicNEOTM microbes in this incubator will significantly reduce the cost to purchase the strains. The microbes are automatically injected into wastewater treatment plants. ElbicNEO IncubatorTM is especially useful in treating wastewater containing a large amount of fat and chemicals because it can continuously provide a lot of microbes. For this reason, the incubator has been installed in dairy and other food processing factories, which extensively produce dairy cream and shortening.

III. Two-Step System: ElbicYoutry-1TM & ElbicBZ-OTM

A large amount of lipid (oils and fats) is found in wastewater from food and beverage factories. In wastewater treatment systems, however, decomposing lipids is challenging. Effective treatment of lipids proposed by the company involves two steps; 1) emulsification and dispersion, and 2) enzymatic hydrolysis. In the first step, ElbicYoutry-1TM, a specially developed non-toxic surfactant, is used. When the surfactant is injected into a water tank via Automatic Injection Device, it reduces the surface tension of water and quickly disperses lipids into small particles. In the second step, the wastewater is transferred to an aeration tank, and ElbicBZ-OTM is injected. ElbicBZ-OTM is a family of Bacillus subtilis and contains highly active enzymes (lipase and phospholipase). With the enzymes, lipids are broken down into free fatty acids and glycerin, which can be digested in the activated sludge.

The Elbic Series is a practical wastewater treatment solution in food processing industry.

Technology Data

Technology data

Conceivable applications

Since the beginning of 20th Century, activated sludge method has been widely used in domestic wastewater and industrial effluent treatment. However, food processing industry has been and are facing serious challenges in wastewater treatment since Hazard Analysis and Critical Control Points (HACCP) system was officially introduced in Japan in 1996.

Prevalence of the HACCP system forces food processing industry (i.e. food and beverage processing, dairy operations and meatpacking) to use much more detergents and pesticides, which are discharged in wastewater, than before. Excessive amount of detergents and pesticides in wastewater could weaken or exterminate microorganisms in the activated sludge which are to be used for decomposing organic matters into carbon dioxide, water and ammonia (i.e. hindering aerobic wastewater treatment).

Hinode Sangyo Co., Ltd. has developed practical solutions in terms of both cost and performance to address the foregoing challenges. Conceivable applications of our solutions are as follows:

1. Wastewater treatment for all-round food industry, including food and beverage processing, dairy operations, meatpacking, palm oil mill effluent (POME), cattle breeding, aquaculture.

2. Wastewater treatment for restaurants, hotels, condominiums, shopping malls and commercial facilities.

Competitive advantage

1. Food processing plants discharges wastewater having very high BOD with carbohydrate, oil/fat and/or proteins, sometimes with high density of detergents/pesticides. Our technology is designed to consistently reduce BOD to acceptable levels set forth by law.

2. Assuring stabilized and efficient wastewater treatment by proprietary highly effective microorganisms.

3. Making operation of wastewater treatment plants easier with reduced running cost, in particular, substantial cutback of excessive sludge (industrial waste) generation.

4. Safety.

5. Energy cost cut.

On top of the competitive advantages mentioned above, we also have developed a microbubble aerator, so-called “HINODE MICROBUBBLER™ (HMB)”, which enables dissolved oxygen (DO) rate to at least 160% of that of raw effluent even under difficult condition such as high viscosity, contained in shallow water tank or equipped with air blowers of insufficient capacity. HMB is designed to simultaneously and uniformly disperse microbubbles and Hinode’s microorganisms (i.e. ElbicNEO and ElbicBZ-O) and the surfactant (i.e. Yourty-1 agent) in water, which optimizes the efficiency of microorganisms and surfactant. HMB also minimizes electricity consumption. This wastewater treatment process is named “Hinode Microbubbler System.” Existing aeration blower requires highly-pressurized air at the bottom of water tank, while HMB suctions air by utilizing negative pressure, which enables HMB placed either inside or outside of water tank for generating microbubbles in water.

Performance

1. Elbic NEO™ (Concentration culture medium contents Bacillus Subtilis strain) System:

Wastewater of food/beverage processing plants contains high density of organic matters as well as detergents/pesticides and rinse water of Clean-in-Place (CIP) systems required by HACCP, which renders tremendous difficulty to conventional wastewater treatment systems. Microorganisms living in ordinary aeration tanks are unable to survive wastewater containing high density of organic matters due to lack of dissolved oxygen. Chlorine or invert soap contained in detergents instantly eradicates microorganisms, which leaves organic matters in wastewater untreated.

ElbicNEO microorganism survives such kind of harsh environment by sporulation, and starts growing as soon as nutrients are in place. Regardless of the characteristics of discharged wastewater, continuous injection of ElbicNEO ensures stable and consistent treatment of wastewater even in the conventional aerobic treatment systems.

ElbicNEO is highly-effective microorganism having the following remarkable advantages:

– High capability of decomposing protein, oil/fat, corbohydrates

– Suppressing growth of coliform;

– Highly dispersible, and staying active even under low resolved oxygen:

– Fast growth at an exponential rate through cell division every 20 minutes;

– Acting vividly to consume energy; and

– Sporulating to gain protection against detergents/pesticides, heat and pH.

2. ElbicNEO Incubator™:

Hinode Sangyo Co.,Ltd. has developed an incubator to incubate ElbicNEO microorganism on-site. ElbicNEO Incubator can proliferate ElbicNEO microbes by 25 times just by pouring clean (tap) water into the incubator. ElbicNEO incubator is operated fully automatically to control continuous injection of ElbicNEO into wastewater treatment plants in an appropriate manner. It also helps significantly reduce the cost of ElbicNEO microorganisms.

ElbicNEO incubators have been installed at the wastewater treatment facilities of dairy operations plants and food processing factories that extensively use dairy cream and shortening. Those plants and factories discharge high-fat effluent and a large volume of detergents/pesticides.

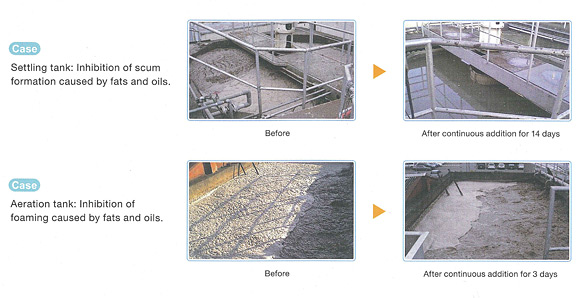

3. Two-Step System (ElbicBZ-O™ along with ElbicYoutry-1™):

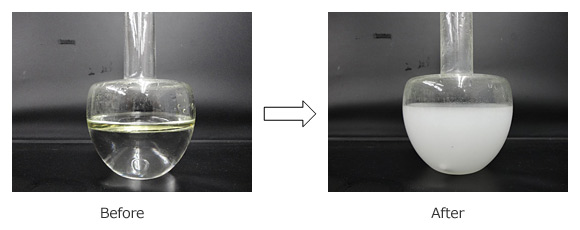

Step 1: Youtry-1 is injected in the adjusting tank through Automatic Injection Device for efficient emulsification and dispersion of oil/fat.

ElbicYoutry-1™

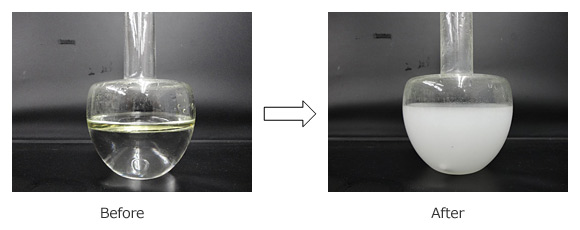

Oil/fat forms oil/fat layer in conventional wastewater microbial treatment systems find it difficult to remove oil/grease efficiently. Intensive aeration forces large clusters of oil/fat to float on the surface, which prevents contact with decomposing microorganisms in activated sludge. ElbicYourty-1 was developed to solve the foregoing problem. ElbicYourty-1, a sugar-family special surfactant agent, which is safe to humans, animals and plants. By virtue of its strong emulsifying capacity, Elbic Youtry-1 reduces surface tension of water, and quickly disperses oil/grease to small particles so that ElbicBZ-O can efficiently decompose oil/fat in the next step.

Step 2: Wastewater is transferred to aeration tank where ElbicBZ-O is injected to hydrolyze the lipids to fatty acid and glycerin by virtue of lipase generated by ElbicBZ-O. Free fatty acid is easily decomposed to water-soluble acetyl compound, and digested along with glycerin by activated sludge.

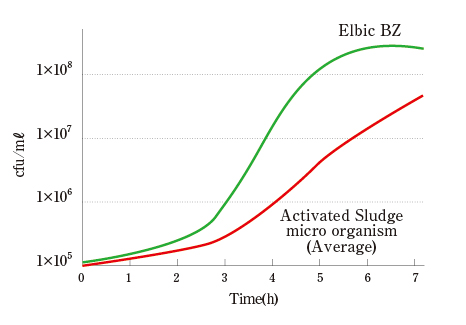

ElbicBZ-O™

ElbicBZ-O, family of Bacillus Subtilis, have the advantages as follows:

– Containing highly active lipase and phospholipase;

– Superb decomposition capacity of higher fatty acid;

– Fast proliferation;

– Sporulating to gain protection against environmental aggravation (poor nutrient, inflow of pesticides, acid and alkaline) and

– Bacillus Subtilis belongs to the same family of NATTO (Japanese food)bacterium, which has been proved to be safe over the past centuries. Bacillus Subtilis cohabits with microbes in activated sludge and enhances decomposition capacity.

Effluent discharged from food processing plants and beverage factories contains high concentration of oil and fat. Currently, oil and fat are flocculated and floated with pressurized resolved air, which results in generation of enormous amount of froth to constitute 50 to 80% of the total excessive sludge. This process is referred to as physical separation method, while Hinode Sangyo Co,,Ltd. offers microbial decomposition/degradation of oil/fat, whose advantage is to substantially reduce total excessive sludge without using flocculants.

Technical maturity / Past record of introduction

Hinode Sangyo has successfully developed state-of-the-art microorganisms solutions, having supply records in 2012 and in 2013 as follows:

1. ElbicNEO System™ (microorganisms with incubator): seven units

2. Elbic Twin Micro Bubble System™ : four units

Conceivable risk

Hinode Sangyo’s microorganisms, Bacillus Subtilis, pose no hazard to humans, animals, plants and environment.

Information on patent related to this technology

“Norvel Batillus Microbes and Use of Same”, Patent No. PCT/JP2013/055504 filed under Patent Cooperation Treaty (PCT).

Company Data

| Name | HINODE SANGYO Co., Ltd. |

| Address | 3854, Ikebe-cho, Tsuzuki-ku, Yokohama City, Kanagawa 224-0053 Japan |

| Capital | Japanese yen 20,000,000 |

| Contact person | Kaori FUJITA Tel: +81-45-507-3031 Fax: +81-45-507-3032 Email:k-fujita@hinodesangyo.com Corporate website: https://www.hinodesangyo.com/english/ |

| Number of employees | 12 (1 for international operation) |

| Date of company foundation | September 1976 |

| The type of business | Providing proprietary solutions (microorganisms) for waste water treatment |

Modality of business transaction

Partnership

HINODE SANGYO is looking for business partners, particularly trader and/or equipment fabricator. The company will provide them with comprehensive wastewater treatment solutions including supply of microorganisms and equipment, and operation training. Q&A service as well as customer support service will be undertaken and supported by Hinode Sangyo’s headquarters.

Export of product

HINODE SANGYO is looking for buyers of their product. The company believes that their products, Elbic Series, is the most practical solutions for wastewater treatment. Construction of wastewater treatment plant will be conducted from design to commissioning on a turnkey basis.

Licensing of patent

Patent licensing will be available in Thailand and Vietnam, where Hinode Sangyo has filed patents under Patent Cooperation Treaty (PCT).

Attachments

Schematic illustration of the technology

1. ElbicNEO Incubator™

2. Microorganism growth comparison between ElbicBZ and others

3. Cases of the impact of ElbicBZ on water treatment

4. Video 2: Elbic Youtry-1 (Oil/Fat Treating Agent)

5. Before and After: Elbic Youtry-1

6. Effluent Treatment Process and Elbic Series

7. Case Study of Hinode Microbubbler (1)

Electricity Consumption significantly reduced at the Wastewater Treatment Plant (Discharging Capacity: 700m3/day) at a Food-processing (noodle manufacturing) Factory which has installed HMB since June 2013.

Impact of HMB on Power Consumption for Aeration at Food Processing Factory

Before installation of HMB, the factory operated five aeration blowers with power consumption of 52.6KWh.

(Note) Power tariff: JPY20/KWh Power cost:JPY20/KWh

8. Case Study of Hinode Microbubbler (2)

A large-scaled processing plant for daily dish and side dish for lunch box introduced Hinode Microbubbler System (HMB and ElbicBZ microorganisms) for the purpose of eliminating unpleasant odors generated by hydrogen sulfide contained in its wastewater. HMB and ElbicBZ are used in the raw effluent tank.

Hydrogen Sulfide (average values) measured at the indoor treatment plant

N.D.= Not Detectable

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control / Circular Economy (3R)