Simplified & Low-Cost Water

Purification System

Water purification systems are essential in some areas. Many purification systems require electricity and can be expensive. The system developed by KAWATOKU CO., LTD. is a low-cost solution which requires no power. The system consists of a manual stir pump and flocculating agents. Heavy metals including iron, arsenic, and fluoride can be easily removed through a process called flocculation, in which sediments are collected at the bottom of the tank. The system can be used to purify well water as well as water from rivers, lakes, and marshes.

Major Features and Advantages

I. No special tank is needed

The system can be installed in a tank made of any materials including concrete, stainless steel, and polyethylene. There is no need to purchase a special tank for the installation. A tank is first filled with unpurified water, and the manual stir pump is placed inside the tank.

II. Amount of Treatable Water

The maximum amount of water to be purified in a single tank is five cubic meters (five tons) with a manual stir pump. The manual stir pump is not required when the water purified is a small amount.

III. Flocculating Agent

A flocculating agent is added to the unpurified water before the water is stirred manually. The amount of the agent must be precise (about 150 to 300 grams/m3 of water). The ingredients of the agent are determined through a water analysis, but they contain a special safe additive produced by Nippon Poly-Glu Co.Ltd. The additive is based on PGα21ca, which is produced using the bacteria called Bacillus natto.

IV. Easy-to-Use Manual Stir Pump

IV. Easy-to-Use Manual Stir Pump

The manual stir pump used in this system is specially developed by the company. It is durable and comes in different sizes depending on the size of the tank. The operation is easy. Even women, children and elderly can turn the handle. When the handle is turned, water is spiraled up and down with the help of screws. The stirred water dissociates into purified water and sediments. The accumulated sediments can be removed through a valve located at the bottom of the tank.

V. Cost

Cost depends on the quality of local water to be processed. Local water must be first analyzed for its contents, and the result will be used to determine the material composition of the flocculating agent. The cost of the manual stir pump for a 1,000-liter water tank is 250,000JPY, while that of a flocculating agent per 20kg is from 25,000 to 30,000JPY.

VI. Easy Maintenance

VI. Easy Maintenance

The entire system is simple and requires little maintenance.

The system is currently being used in various countries. In Tanzania, fluoride is removed from the well water so that its quality meets the WHO standards. In Myanmar, the system is used to purify water used in a medical facility.

Technology Data

Conceivable applications

Purification of turbid water into drinkable water by removing heavy metals, such as iron, arsenic, and fluorine.

Competitive advantages

To the best of our knowledge, there is no company offering a technology at this point that can remove iron, arsenic, and fluorine at a lower cost than our company can.

No need for electric power. Simple device.

Performance

This technology reduces heavy metal contents, such as iron, arsenic and fluorine, and purifies turbidity at low cost. The technology is based on flocculent settling, and can work without electricity. Turbid water can be agitated manually, by hand. This technology can be installed in existing tanks made of any materials.

The cost depends on the quality of the local water to be processed. Analysis of the local water is necessary. The element of the additive is determined according to the water analyses data.

Devices are simple and need very little maintenance.

Past records of the water treatment are as follows:

Turbidity; 4.5 ppm -> less than 0.5 ppm

Turbidity; 0.48 % -> less than 0.5 ppm

Iron contents; 10.7 ppm -> 0.27 ppm

Arsenic; 8 ppb -> 3 ppb

Fluorine; 4.92 ppm -> 1.31 ppm

There is no limit for the amount of water to be processed.

When there is little water to be processed, the manually operated stir pump is not necessary.

The upper limit for the amount of water in one tank is 5 cubic meters (5 tons) with a manually operated stir pump. If two or more water tanks are arranged and set up, our equipment can process more than 5 cubic meters (5 tons) of water.

Technical maturity

In Tanzania, fluorine content in the well water often exceeds the standard of the WHO, even when people are careful to select a location to dig a well. We keep making an effort so that people in Tanzania are helped by removing fluorine from the well water.

In Myanmar, a Non-Profit Organization requested our company’s help to secure enough water at a medical treatment facility. Our air lift stir machine and flocculating agents successfully operated to secure enough water for medical use, such as washing hands.

*Note: This technology does not guarantee that any kind of water can be purified with this system to meet the WHO “Guidelines for Drinking-water Quality” (fourth edition).

Conceivable risk

Flocculating agents are harmful if inhaled or swallowed beyond certain levels.

It is advisable to keep flocculating agents away from humidity. The sediments generated from this process should be treated as a waste according to local laws and regulations for waste treatment.

Information on patent related to this technology

Nothing

Company Data

| Name | KAWATOKU CO., LTD. |

| Address | 8-26, Kita-Okinosu, 1-chome, Tokushima-shi, Tokushima 770-0872, Japan |

| Capital | 300 million JPY |

| Contact person | Mr. Hirofumi SUGANO Tel: +81-88-664-8238 Fax: +81-88-664-6731 E-mail: kawatoku@ivy.ocn.ne.jp |

| Number of employees | 4 (1 for international operation) |

| Date of company foundation | September 2008 |

| The type of business | Simplified water purification system |

Modality of business transaction

Partnership

Technical guidance in cooperation with the local firm, establishment of a joint venture corporation, and business development.

Export of product

In a phased manner

Attachments

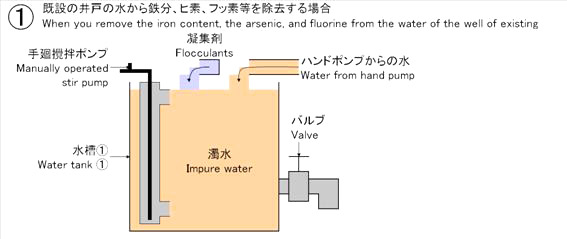

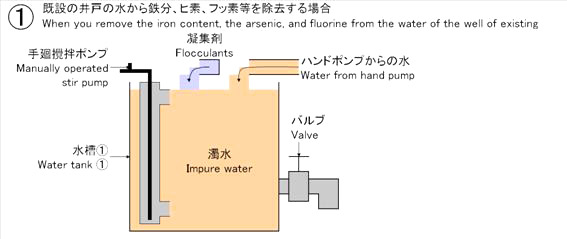

Overview of the system with equipment for the water treatment process

(in the case of the water in a well)

1) Please clean the inside of the water tank to get drinking water.

2) Please put the water in the water tank.

3) Our technology can operate with any kind of water tank. Please use the existing one.

4) There is no problem even if the water tank is made of concrete, stainless steel, or polyethylene.

5) Please choose the size of the manually operated stir pump and water tank according to the volume of water used.

6) Please put flocculants in the water tank with water in the proper quantity(Please put about 150-300 gram in the water of 1 cubic meter. ).

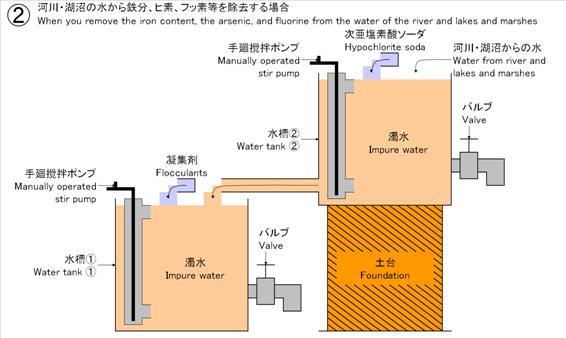

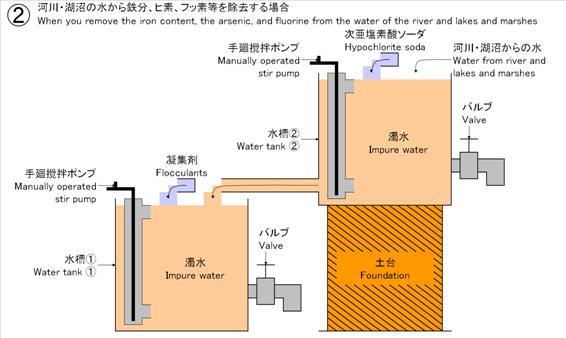

Overview of the system with equipment for the water treatment process

(in the case of the river water or lake water)

Steps 1) to 6) are the exactly same procedure to the case of the water in a well.

7) The hypochlorite soda sterilizes miscellaneous germs included in the water of rivers, lakes and marshes.

8) Please use the product normally used in each country as a sterilizer, though hypochlorite soda is generally used in Japan.

9) Please put flocculants in the water tank with water in the proper quantity(Please put about 150-300 grams in 1 cubic meter of water. ).

Picture of the pump

– Our company produces the manually operated stir pump as an apparatus to stir the water of the water tank.

– The water in the water tank is stirred by turning the handle of the manually operated stir pump.

– In the pump, water is spiraled up or down with the help of a screw.

– Even women, children, and the elderly can easily turn the handle.

– It is very hard to be broken.

– The pump can be prepared according to the size of the water tank used.

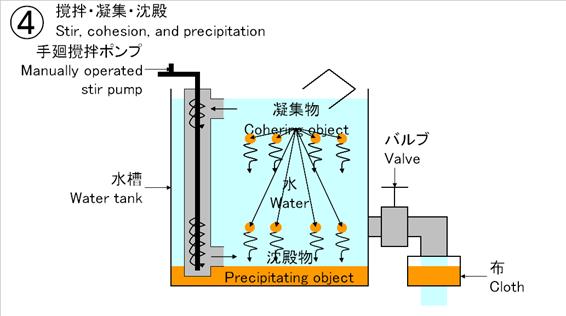

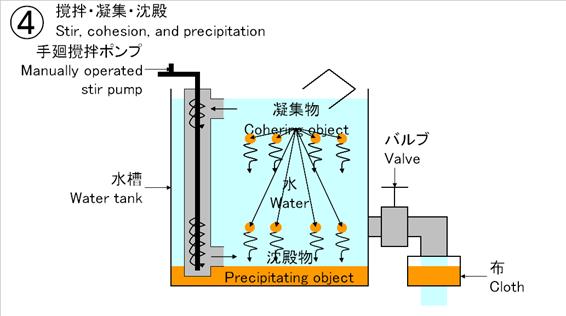

Stir, cohesion, and precipitation

1) Please stir the water in the water tank with the manually operated stir pump.

2) After a few minutes, the stirred water is separated to purified water and sediments.

3) Please dip the purified water for use.

4) The accumulated sediments can be removed through the valve on the bottom of the tank.

5) Please process sediments as waste when iron, arsenic, and fluorine are contained.

6) The sediments generated from this process should be treated according to local laws and/or regulations for waste treatment.

About flocculating agents

Our flocculating agents are manufactured by adding a safe additive as food based on PGα21ca made from the bacillus natto that is a product of Nippon Poly-Glu Co.,Ltd. Because of the iron, the arsenic, and fluorine cannot be removed, and other flocculating agents cannot be used.

About the cost

It is not predicable because it depends on the quality of local water. For reference, a manually operated stir pump for a 1000-liter water tank costs 250,000 yen. The flocculating agents for 20 kilograms cost from 25,000 to 30,000 yen. However, this is the price for delivery in Japan.

Comparison of original turbid water with treat water

Contact Person(s)

*Please mention that you saw UNIDO's website when making the first contact with the company.

Registered Category

- Environmental Technologies : Pollution Prevention and Control